Diagnosis of the root cause of failure

The diagnosis of the root cause of failure is an essential service for industrial companies seeking to accurately identify the source of problems in materials, equipment or processes.

At INFINITIA Industrial Consulting, we approach this activity with a technical and methodological approach that allows us not only to detect the failure, but also to understand its causes and apply effective solutions to prevent its recurrence.

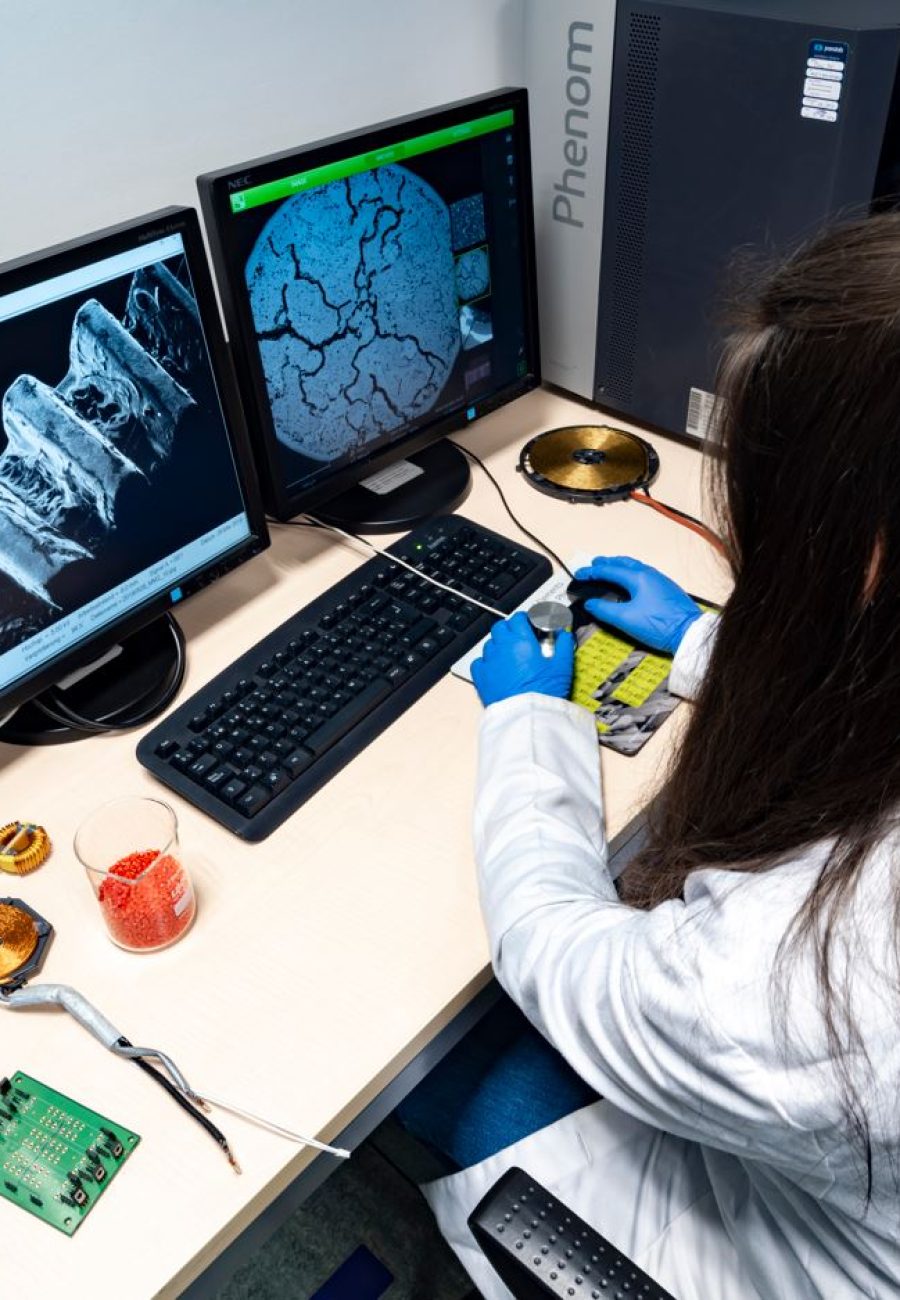

In our industrial laboratory, we have specialists in forensic engineering and failure analysis who work with the latest technologies to carry out comprehensive, rigorous and results-oriented studies, integrating techniques such as comparative sample analysis, failure simulation and hypothesis validation through specific tests.

What is root cause failure diagnosis?

Root cause analysis, also known as RCA, is a structured process for investigating and determining the underlying factors that cause a particular failure in components, systems or industrial processes.

At INFINITIA, we use tools such as the Ishikawa diagram to establish hypotheses, which are then subjected to testing and laboratory analysis, prioritising the most likely ones. This approach provides in-depth knowledge of how and why the failure occurs and provides a solid technical basis for making corrective decisions.

The process can include both the analysis of NOK materials against OK samples and specific simulations of the failure under controlled conditions, ensuring accurate identification of the problem.

Benefits/Advantages of root cause analysis

One of the main benefits of root cause analysis is the prevention of recurring failures, which translates into significant savings in time, production costs and quality losses. For example, a company in the automotive sector managed to avoid unplanned downtime thanks to a root cause diagnosis of the failure in some components carried out in our laboratory.

Another relevant case was the identification of incompatibilities between materials in a production machine, which was solved thanks to diagnosis, simulation of the problem and testing of viable alternatives.

At INFINITIA, we add value not only by resolving the current failure, but also by anticipating its recurrence, facilitating continuous improvement and decision-making based on objective data.

Diagnosis of the root cause of failure at INFINITIA

At INFINITIA, we take a comprehensive approach to industrial fault diagnosis. We start with an initial hypothesis based on a functional analysis of the affected component or system and, from there, we design a validation plan that includes material characterisation techniques, simulation tests and comparative sample analysis.

We work with advanced technologies in spectroscopy, microscopy, thermal and mechanical analysis, which allows us to detect even faults that are not visible to the naked eye. In addition, we can repeat tests with different raw materials or equipment configurations to propose robust technical solutions. Our approach is focused on the customer and their problems, adapting to each case with tailor-made solutions.

Types of root cause failure diagnosis

At INFINITIA, we develop different diagnostic approaches to accurately analyse the causes of failure in components, materials and industrial systems.

We apply structured methodologies such as RCA, 8D or Ishikawa, combined with technical tests, to validate hypotheses and propose specific solutions. Our goal is to identify the source of the failure and prevent its recurrence by optimising processes, materials and technical decisions.

Diagnosis using Ishikawa diagrams and hypothesis formulation

This approach starts with a collaborative assessment with the client to build a cause-and-effect diagram (Ishikawa), which classifies the possible sources of the failure (materials, methods, machinery, workforce, environment, measurement). From there, hypotheses are proposed and a technical validation plan is established.

At INFINITIA, we have used this approach with various clients and industrial sectors to identify the interaction between metal coatings and certain chemicals that were causing premature corrosion.

Diagnosis through hypothesis validation tests

Once the possible causes have been identified, we design and carry out laboratory tests (thermal, chemical, mechanical, etc.) to validate or rule out hypotheses. This methodology allows us to refine the diagnosis in an empirical and objective manner.

A common example at INFINITIA is the analysis of cracks in plastic parts using impact and ageing tests, which has enabled us to reformulate materials in consumer products to increase their durability.

Simulation of failure under controlled conditions

When the failure is complex or does not occur systematically, the conditions of the industrial process are replicated in the laboratory to induce the failure in a controlled manner. This allows the actual failure mechanism to be observed and critical factors to be evaluated.

In a project for industrial machinery, INFINITIA simulated humidity and friction conditions that allowed failures in components to be reproduced, optimising the design of the sealing system.

Comparison between OK and NOK samples

This comparative analysis between defective (NOK) and correct (OK) samples allows us to detect critical variations in physical, chemical or structural properties that explain the failure.

For example, for a client in the industrial sector, we identified a difference in the degree of curing of a resin between OK and NOK parts that was causing structural failures in the housings after assembly.

Diagnosis using 8D methodology and follow-up of corrective actions

In cases where diagnosis is part of a structured quality process (e.g. in response to customer complaints or audits), INFINITIA applies the 8D methodology, documenting each stage and establishing verifiable corrective actions.

We have collaborated with automotive companies on 8D analysis to resolve serial defects, with hypothesis validation and solution finding through pilot testing prior to implementation.

Applications of root cause failure diagnosis

Root cause failure diagnosis is essential in many industrial sectors, especially where product reliability and process continuity are key. At INFINITIA, we help identify and eliminate the causes of failure, promoting continuous improvement and informed technical decision-making.

Automotive industry

In the automotive sector, quality requirements are extremely demanding. A production failure can lead to significant financial losses, affecting reputation and operational continuity. Diagnosis allows recurrences to be prevented, components to be redesigned and production processes to be optimised.

- Diagnosis of cracks in electrical connectors subjected to thermal cycles.

- Prevention of failures in ventilation system components with moisture present.

- Comparative analysis of injection parts to detect variations in their composition.

Appliances and consumer goods

The durability and resistance of consumer products is key to minimising returns and complaints. Diagnostics allows design errors or faults due to material incompatibility to be detected. This contributes to product improvement and cost reduction.

- Study of breakages in plastic components during transport.

- Identification of incompatibility between materials in welding processes.

- Diagnosis of deformations due to thermal stress.

Food and packaging

In this industry, any failure in packaging can compromise food safety or shorten the shelf life of the product. Diagnostics can detect faults in materials, sealing processes or contamination, ensuring regulatory compliance.

- Evaluation of sealing faults in multilayer films.

- Analysis of undesirable migration detected in audits.

- Simulation of storage conditions to validate new packaging materials.

Energy and electronics sector

Failures in power electronics or energy storage system components can lead to critical shutdowns or safety incidents. Diagnostics helps to understand the failure mechanisms associated with temperature, humidity or electrical voltage.

- Evaluation of failures in dielectric materials.Study of accelerated oxidation in electronic components.

- Simulation of load cycles and thermal stress.

Medical devices

In the medical field, materials must meet strict biocompatibility and stability requirements. Fault diagnosis ensures device functionality, detects deviations in manufacturing processes and validates changes in suppliers.

- Diagnosis of cracks in components after sterilisation.

- Comparative analysis of NOK vs OK plastics that show yellowing and aesthetic defects.

- Simulation of repeated use in disposable devices to validate service life cycles.

The future of failure prevention starts with a good diagnosis

Root cause failure diagnosis is an essential strategic tool for companies in the industrial sector seeking to guarantee quality, reduce costs and optimise their processes.

Through a structured technical approach based on methodologies such as RCA, 8D or the Ishikawa diagram, it is possible to identify the real source of a failure, validate it through specific tests and apply effective corrective solutions. This ability to understand the problem in depth is key to preventing its recurrence, improving decision-making and increasing product reliability.

At INFINITIA Industrial Consulting, we offer a comprehensive diagnostic service that integrates expertise in forensic engineering, materials analysis and failure simulation. Our experience allows us to tackle complex problems in sectors such as automotive, food, electronics and medical devices, adapting each study to the client’s requirements.

We have a laboratory equipped with advanced technologies and a specialised technical team capable of proposing hypotheses and validating solutions through customised testing.

In addition, we are seeing a growing trend towards the automation and digitalisation of failure analysis, the integration of predictive models and the automation of validation processes.

In this context, having INFINITIA on your side is not only a technical guarantee, but also a strategic asset. We help you turn failures into opportunities for improvement, anticipating problems before they occur.

Trust INFINITIA to carry out root cause failure diagnosis with precision, rigour and a results-oriented approach.