3D printing

Discover the 3D printing service that we carry out in the INFINITIA laboratory. We use the most cutting-edge technology to offer quality work to our clients. No matter the type of company or sector, at INFINITIA we can help you.

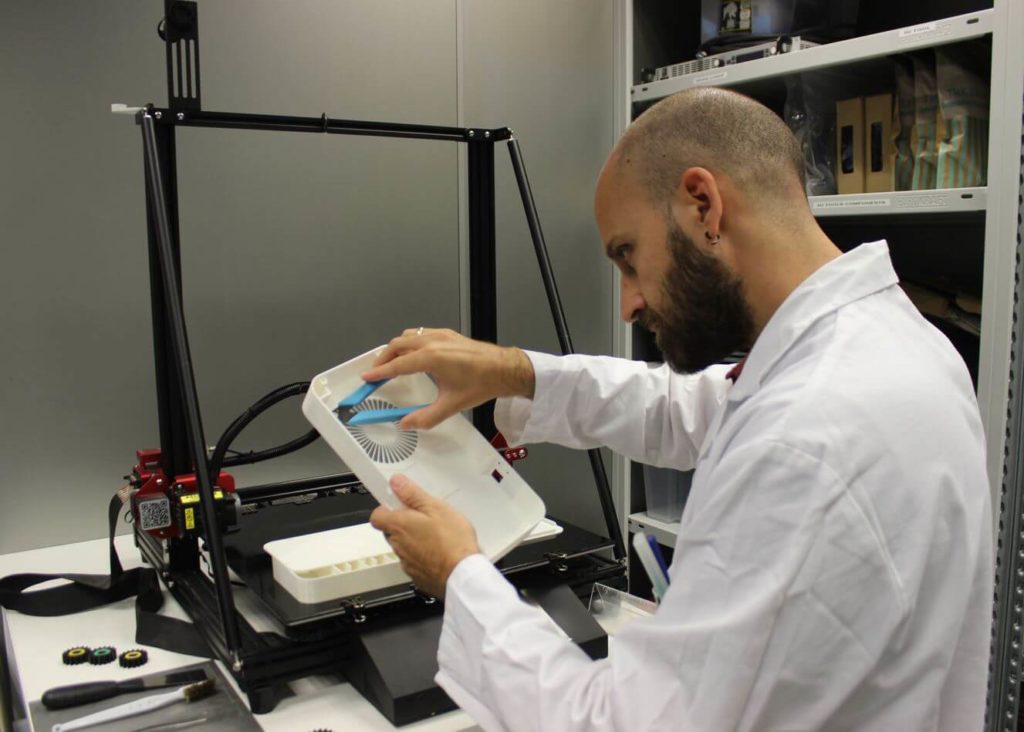

In addition to a fully equipped laboratory we are a group of professionals trained and experienced in 3D printing. Different specialists come together to create this type of prototypes that allow parts to be validated with greater efficiency and operability. Find out about 3D printing at INFINITIA now!

What is 3D printing?

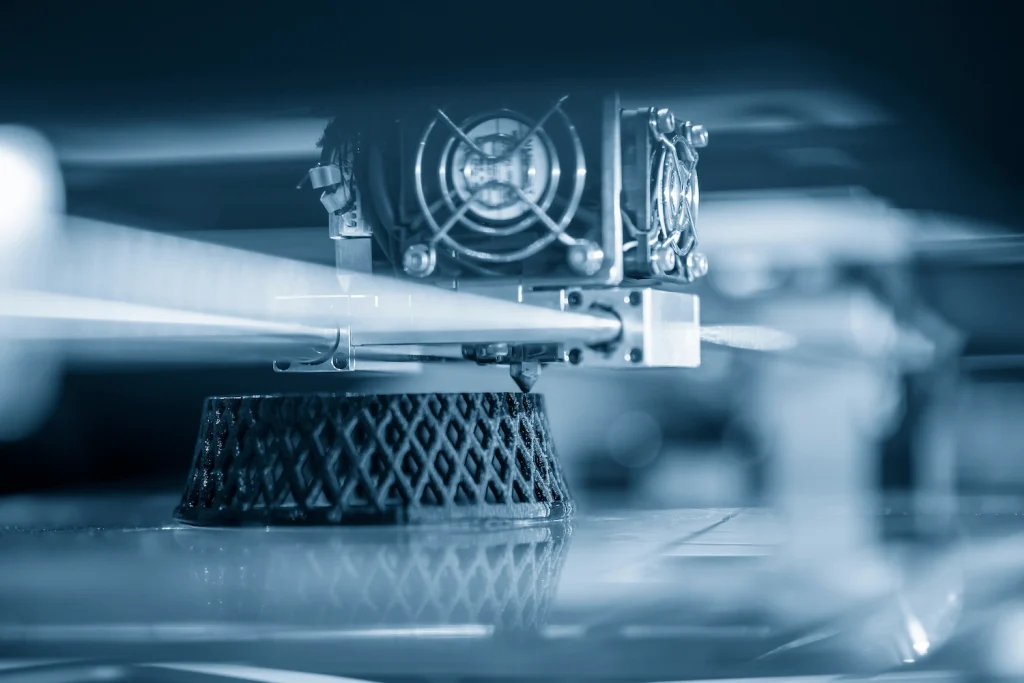

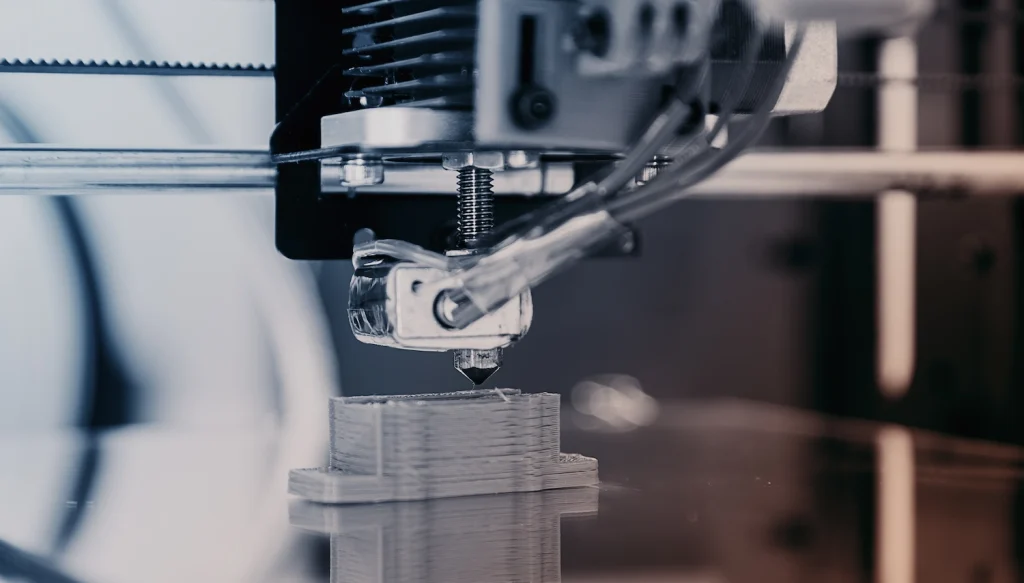

Nowadays, there are different types of prototyping. One of them, and widely used, is 3D printing. 3D printing is a technique that allows the creation and adaptation of three-dimensional elements.

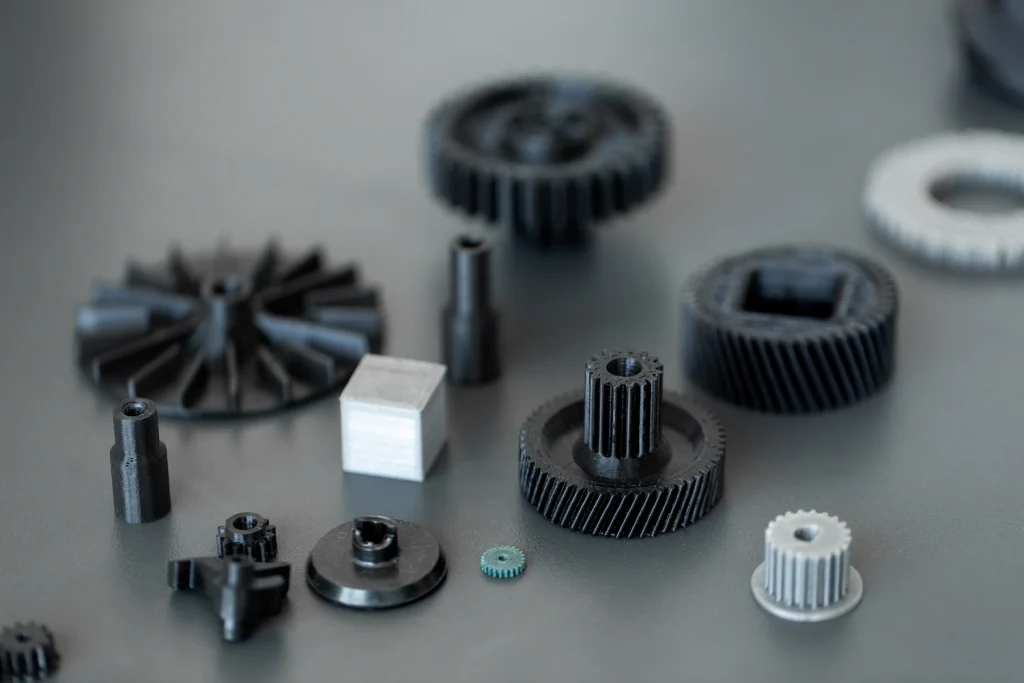

These objects are created by adding material layer by layer. This is usually plastic or metal, although depending on the type of 3D printer, different raw materials can be used, such as living tissue or concrete.

Estos objetos se crean añadiendo el material capa a capa. Este, normalmente, se trata de plástico o metal; aunque dependiendo del tipo de impresoras 3D se pueden encontrar diferentes materias primas como tejidos vivos u hormigón.

Contact with us

Contact us for more information or, if you prefer, you can use one of our other technical consultancies with complementary services to boost your project.

3D printing parts to validate concepts

With the 3D printing in resin or any other material such as thermoplastic, we validate and redefine a new concept, model design or even allows us to prepare tooling. A key fact for carrying out the development of a product in a fast and efficient way.

In this way, from the INFINITIA laboratory we first validate the prototype of the future product. Only when the product has been approved by the client, we manufacture it industrially. This means that we not only optimize time, but also a large amount of economic resources.

3D Printing Service Applications

Any sector, industry or company can benefit from 3D printing. This technique generates transversal products, parts and components that adapt perfectly to customer demand.

In this way, both the Aerospace, agriculture, and automotive industries may need 3D printer designs. But the food sector has also been opting for this technology for food printing for years. If you want to know more about this, the INFINITIA team can help you.

Advantages of validating your product before manufacturing

Why opt for 3D printing? Here are some of the reasons to choose this service:

- Reduce costs: Taking a part directly to industrial manufacturing entails a very high economic risk. If the part or component presents some type of fault, which could not be considered during the validation of the prototype, it will mean a great loss of resources.

- Quality: The iteration that 3D printing allows is synonymous with greater performance, efficiency and quality in the final parts and components.

- Personalization: Since costs are lower than in industrial manufacturing, 3D printing allows for the creation of custom parts, jobsad hocfor different industries.

- Ecology: Working with an industrial 3D printer also helps to optimize material resources and, therefore, avoid wasting materials.

Examples of our 3D printing work

Here are some examples of our industrial 3D printing work:

- 3D metal printing using Binder Jetting technology: It is worth noting this first example where we carry out three-dimensional pieces through the 3D Binder Jetting printing technique, which allows generating pieces in an additive manner through a binding agent.

- 3D printing to detect design flaws in sealed parts 3D printing can also be used to redesign parts that require specific characteristics. In this example, these are 3D parts with internal sealing requirements to prevent leaks.

- 3D printing for the presentation of a new product at a trade fair: In record time, we created 3D parts that had to incorporate the hardware inside an aesthetic casing to be displayed at a trade fair. Hence, these designs for 3D printers had a dual purpose, both aesthetic and functional.

- 3D printing and testing of a laser engraving robot: In this case, given the short lead times and the lack of final parts, we carried out rapid prototyping to test with the robot on site.

Contact with us

Contact us for more information or, if you prefer, you can use one of our other technical consultancies with complementary services to boost your project.