Adhesion tests

Did you know that adhesion tests are essential to assess and guarantee the quality of adhesive bonds in materials? A type of test that is especially important in sectors such as the automotive, construction, aerospace and industrial product manufacturing industries, where materials are subject to high levels of safety.

In the INFINITIA laboratory we determine the effectiveness of adhesives and coatings, as well as the characterization of adhesion to materials. We ensure their resistance, durability under demanding conditions of use, and minimizing failures.

We approve materials and develop new products, always using the most advanced techniques. Find out what we can do for your project. Contact us without obligation.

What are adhesion tests on materials?

Material adhesion testing consists of a series of tests designed to evaluate the ability of an adhesive or coating to bond to a surface, and maintain that bond under various conditions. These tests are essential to validate adhesion strength and ensure that materials meet quality and safety standards.

In our laboratory we carry out surface adhesion tests to analyse how adhesives and coatings interact with different base materials (metals, plastics, glass and composites). This analysis is crucial for applications where adhesive bonds must withstand mechanical forces, temperature changes and prolonged chemical exposures.

Contact with us

Contact us for more information or, if you prefer, you can use one of our other technical consultancies with complementary services to boost your project.

Types of adhesion tests

There are different types of adhesion tests to measure the quality and strength of adhesive bonds and coatings. The most common methods include:

Pull-off test

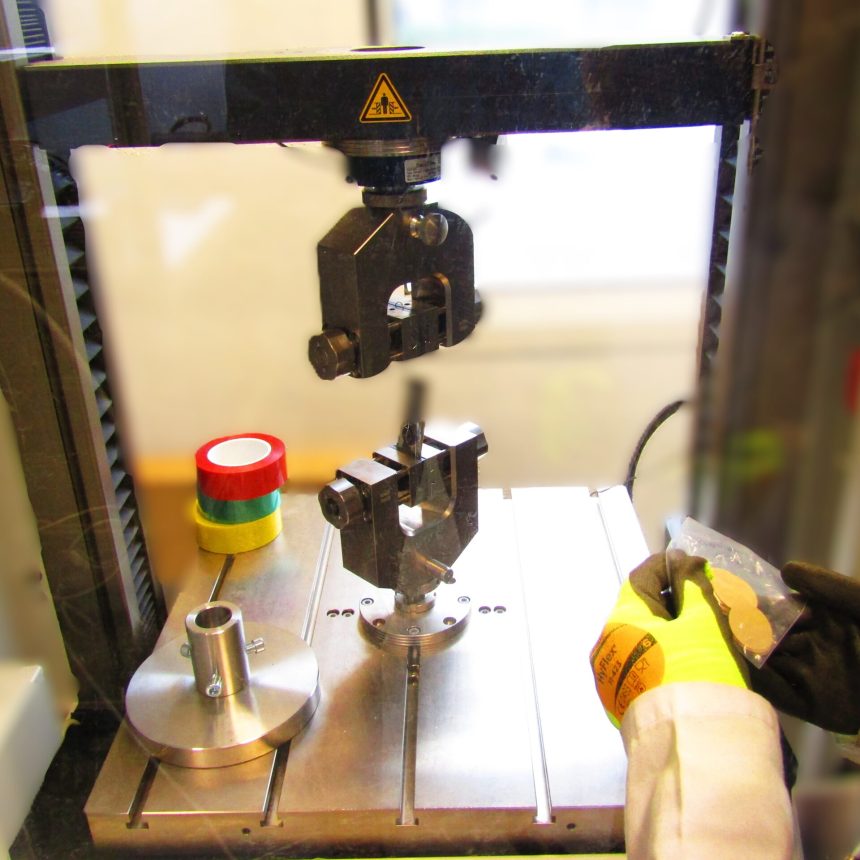

This method measures the force required to separate an adhesive or coating from the surface to which it is adhered. Using specialized equipment, we apply a load perpendicular to the surface until the bond breaks. This provides critical information on the ultimate adhesion strength, which is useful for evaluating structural adhesives and coatings in industrial applications.

Shear test

These glue and adhesive resistance tests are used to calculate the slip resistance between two surfaces joined by an adhesive. Glues and adhesives, which act as mechanical assemblies and laminated structures, are subjected to forces parallel to the bonding surfaces.

Peel test

We perform the evaluation of adhesion strength. By performing tests in which the adhesive is peeled off a surface at a specific angle. This test is used to evaluate flexible adhesives such as adhesive tapes or plastic films, as well as in decorative and functional coating applications.

Adhesion testing on surfaces using scratch tests

This test is performed to determine the adhesion of coatings on metallic and plastic materials. At INFINITIA we use an instrument that applies a progressive force to the coated surface to identify the point at which adhesion failure occurs.

What are adhesion tests on paints and coatings?

Adhesion tests on paints and coatings are a guarantee of quality and durability. These surface adhesion tests are essential to maintain the integrity and functionality of these materials over time. This occurs, for example, with protective coatings applied to metal infrastructures, pipes and industrial products subjected to aggressive environments.

Some of the specific tests performed include:

- Cross-cut test: This is a method of evaluating adhesion strength, specifically for coatings applied to metal and plastic surfaces. Grid-shaped cuts are made in the coating, followed by a visual assessment to determine whether the coating remains adhered or is peeling off.

- Impact resistance tests: This type of adhesion test simulates the effect of impacts and drops on coatings and adhesives to evaluate their resistance to separation or peeling under dynamic conditions. This is what we did to improve enamelling processes using induction heating.

Adhesion evaluation of coatings by thermal testing: To analyse the thermal properties of materials, these tests we carry out at INFINITIA simulate extreme temperature cycles. In this way, we analyse how coatings respond to thermal expansion and contraction. An essential durability test in critical applications such as automotive and aerospace.

Adhesion tests on plastic and metallic materials

Adhesion assessment of coatings and adhesive bonds is particularly relevant for plastic and metallic materials due to their specific properties and applications. These analyses are crucial for industrial applications where adhesive bonds must withstand demanding conditions. This is the case in the manufacture of automobiles, heavy machinery and aerospace components.

Adhesion tests on metallic materials

Metals, on the other hand, often require strong adhesive bonds for structural applications. Our adhesion tests evaluate the strength of bonds under different conditions such as exposure to corrosive environments, high temperatures or dynamic loads, ensuring their performance and durability.

Adhesion tests on plastic materials

Plastics present unique challenges due to their low surface energy and difficulty in achieving good adhesion. Our adhesion testing includes pretreatments such as primer application or plasma surface treatments to assess the impact of these processes on adhesion quality. And discover this example of materials innovation through Atmospheric Plasma technology.

Applications of adhesion testing in industrial materials

We work with all types of industries. These are some of the sectors where we carry out adhesion tests for industrial materials:

- Automotive: We evaluate the strength of adhesives used in joining panels, glass and internal components in the automotive sector. To ensure the safety and durability of joints, we include the characterization of adhesive joints.

- Construction: Adhesion tests are essential for validating the quality of protective coatings and structural adhesives in the construction sector, i.e. facades, windows and thermal insulation elements.

- Electronics: We carry out specific tests for adhesives used in the encapsulation of electronic components. The aim is to ensure their resistance to extreme temperatures and corrosive environments.

Medical industry: Adhesives used in medical devices must meet strict safety and biocompatibility requirements. Our adhesion tests verify the quality of these adhesives under controlled conditions.

Benefits of adhesion testing at INFINITIA

Why trust INFINITIA for adhesion testing on materials? Here are some reasons to choose our laboratory:

- Accurate and detailed results: In the INFINITIA laboratory we use advanced techniques to evaluate the quality of adhesive bonds and coatings, providing reliable data that allows us to optimize products and processes.

- Optimization of manufacturing processes: We improve quality and reduce costs associated with defects. The data obtained from our adhesion tests helps manufacturers to adjust their production processes.

- Adaptation to international regulations: We ensure that all tests comply with international standards such as ISO and ASTM. This ensures that the tested materials are suitable for the global market.

Support in homologation of materials: Our adhesion tests are key to validating adhesives and coatings in critical sectors, ensuring that they meet the highest quality and safety standards.

Rely on INFINITIA for adhesion testing for materials innovation

At INFINITIA we specialise in innovation in materials. And these adhesion analyses on industrial materials are a good example of this. We work with you throughout the entire process, from the first stages of development to validate and approve adhesives and coatings.

We carry out tests on joining materials, including mechanical, thermal and chemical resistance tests, to ensure that the joints meet the most demanding performance requirements. This is how we carry out this laser welding of polymers.

We offer innovative and high-quality adhesion solutions. Our approach enables customers to improve their products and ensure their success in the market. Choose our adhesion testing service now. Choose INFINITIA.

Contact us

If you need a service in adhesion testing, contact INFINITIA Industrial Consulting. An expert team and a fully-equipped laboratory await you. We achieve precise and relevant results for your project. Find out more!

Contact with us

Contact us for more information or, if you prefer, you can use one of our other technical consultancies with complementary services to boost your project.