Catalysts

Learn about our advanced services in industrial catalyst characterization. At INFINITIA Industrial Consulting we are experts in catalyst testing. We work to ensure that these meet the activity, stability and efficiency requirements in the processes in which they are used.

In the quality control and testing process, catalyst testing provides a detailed insight into their chemical, structural and performance properties, allowing our customers to maximize their effectiveness and optimize the lifespan of their products. We perform a complete physical-chemical analysis of catalysts, as well as exhaustive performance tests so that each catalyst is optimized for its industrial application. Find out more about our catalyst testing service now!

What is industrial catalyst characterization?

Within the characterization of materials, it is worth highlighting the characterization of industrial catalysts. The latter gives its name to the set of techniques and tests used to analyze the composition, structure and chemical properties of catalysts. Thus, at INFINITIA, we carry out an in-depth analysis of the composition of catalysts, both physical and chemical, which helps us understand their behavior in specific reactions.

Catalyst testing is used to identify the catalyst’s ability to facilitate reactions, as well as its stability and durability under real-life conditions. At INFINITIA, this type of testing includes everything from an analysis of catalyst composition to the evaluation of chemical properties and performance. All of this allows us to provide critical data to improve production processes and ensure optimal performance in our customers’ products.

Catalytic activity and performance tests: definition

Did you know that catalytic activity tests are essential to measure a catalyst’s ability to accelerate a chemical reaction? At INFINITIA, we therefore carry out performance tests on catalysts that allow us to measure the catalyst’s efficiency in terms of its ability to reduce reaction time and increase the conversion of reagents. This information is crucial to optimising industrial processes and maximising production efficiency.

On the other hand, our catalyst efficiency tests are designed to determine the performance of the catalyst under specific conditions, allowing us to identify the necessary adjustments to improve its effectiveness in industrial applications.

In addition to being able to carry out tests in accordance with standards, we can carry out customised, ad hoc tests and benches, through which we can reproduce real conditions. With these catalyst tests, we ensure that each catalyst is ready to operate at its maximum potential and meet the client’s production objectives. Do you want to know more? Ask us any questions you may have.

Structural characterization of catalysts and stability tests

We analyse the structure and arrangement of the elements in the catalyst. Structural characterisation is undoubtedly an essential phase in the catalyst tests that we carry out with total precision in the INFINITIA laboratory. We use advanced techniques to evaluate the structure and composition, identifying aspects such as pore size, distribution of active phases and specific surface area. These factors directly influence the activity and durability of the catalyst. This is how we ensure that performance expectations are met in the industrial process.

In addition, our catalyst testing includes catalyst stability tests that verify the catalyst’s resistance under extreme temperature and pressure conditions, as well as its ability to maintain catalytic activity over time. This evaluation of catalyst life allows us to anticipate their performance and plan their replacement, optimizing costs and resources in production processes and approving new components.

We use innovative catalyst chemical characterization techniques

Spectroscopy, X-ray diffraction, thermal analysis, electrochemical tests… all of them allow us to offer a detailed view of the chemical and physical properties of the catalyst. At INFINITIA we use various chemical characterization techniques for catalysts that allow us to analyze the elemental composition, molecular interactions and reactive properties of the catalysts.

We identify the active components and their distribution through the analysis of catalyst composition. This allows us to confirm the effectiveness of the catalyst in specific applications. With these techniques, our clients obtain precise information on the composition and reactivity of the catalyst, allowing them to make adjustments to improve its performance and effectiveness. And you, do you need our services? At the INFINITIA laboratory we can help you.

Catalyst life evaluation

Another fundamental aspect of our catalyst testing service is knowing what their useful life evaluation consists of. Catalyst useful life evaluation allows us to predict the durability and optimal operating time of the catalyst under real-life conditions.

We perform studies that simulate catalyst wear and aging, allowing us to predict its long-term behavior and plan its replacement efficiently. This type of physical-chemical analysis of catalysts helps our clients optimize their resources and maintain uninterrupted process efficiency. Our catalyst tests also include the evaluation of the catalyst’s resistance to deactivation, which helps predict its performance in long cycles and under variable operating conditions.

Benefits of catalyst testing at INFINITIA

Having experienced professionals like those who are part of the INFINITIA team is synonymous with success for your business. These are the advantages that our clients have for the characterization of industrial catalysts:

- Detailed analysis of composition and structure: Our advanced analytical techniques allow us to carry out detailed evaluations of the chemical properties of catalysts. We have a deep understanding of the properties as well as the structure of each catalyst, optimizing its performance.

- Activity and efficiency tests under real conditions: In the INFINITIA laboratory we carry out tests on specific catalysts to evaluate the catalytic activity and efficiency of the catalyst in industrial applications.

- Life cycle planning and cost optimization: With catalyst stability and durability testing, our customers can plan their catalyst replacement and reduce long-term operating costs.

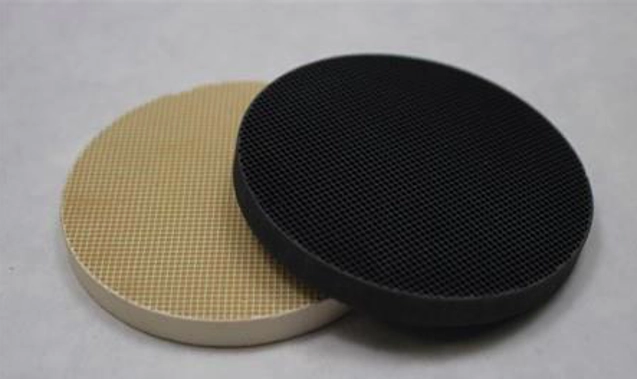

Development of filters with catalysts: With our experience in catalyst testing, we are able to prospect and optimize commercial catalysts. We are also able to develop new catalysts for a custom application where higher performance is required. This is what we did with this development of catalyst filters to eliminate gases and bad odors.

INFINITIA, your testing laboratory for the characterization and chemical analysis of catalysts

From structural characterization to catalyst efficiency testing, at INFINITIA we offer a comprehensive approach that enables our customers to improve their production processes for product enhancement. The goal? Ensuring catalyst performance.

In our laboratory we are committed to innovation and the most cutting-edge techniques, but under an experienced and expert eye. We support our clients in the industrial sector in the testing phase of catalysts for characterization and chemical analysis, so that each catalyst is optimized for its specific application. Discover what we can do for you.

Contact us

Are you looking for experts in physical-chemical analysis of catalysts and efficiency testing? At INFINITIA we are here to help. Our team of specialists and our experience allow us to ensure the required quality and performance standards.