Definition of raw material quality parameters

At INFINITIA, we understand that the quality of raw materials is the first fundamental step in ensuring the excellence of final products in any industrial process.

The correct definition of quality parameters for raw materials allows companies to optimise their production processes, improve the reliability and durability of their products, and comply with the most stringent international regulations.

At INFINITIA, we have a team of highly qualified specialists who work with the latest material characterisation and advanced testing technology, ensuring accurate and reliable results for all industries.

What is the definition of raw material quality parameters?

Defining raw material quality parameters involves evaluating and analysing the physical, chemical and mechanical properties of materials before they are used in production.

This process includes identifying key characteristics such as strength, durability, reliability and adaptability to the specific conditions of each sector.

At INFINITIA, we address this challenge through detailed testing and a thorough review of applicable ISO standards, ensuring that raw materials meet technical requirements and are optimal for use in product manufacturing.

Service benefits

The main benefit of defining raw material quality parameters is the ability to anticipate and prevent failures in the manufacturing process, which significantly improves the efficiency and safety of the final products.

In addition, by identifying the most suitable materials and their specific properties, companies can reduce production costs and improve product reliability.

This service also enables compliance with ISO standards, ensuring that all materials are evaluated according to international standards of quality and safety.

The definition of raw material quality parameters at INFINITIA

At INFINITIA, we carry out the definition of raw material quality parameters with a detailed and personalised approach, using the best techniques and equipment available on the market.

Our tests include mechanical, thermal, chemical and accelerated ageing analyses, all tailored to the specific needs of each customer and sector.

In addition, we ensure that all materials evaluated are aligned with ISO standards and other international regulations, guaranteeing the quality and performance of the final products. And in cases where there is no specific ISO standard to follow, we design custom setups and tests with the aim of reproducing real operating conditions.

Types of tests to define raw material quality parameters

At INFINITIA, we perform a variety of tests to define and validate the quality parameters of raw materials used in industrial processes.

These tests allow us to evaluate the resistance, durability, reliability and behaviour of materials under various conditions of use, ensuring that they meet industry expectations and regulations.

Below, we describe the main tests we carry out:

Chemical composition and structure tests

These tests are essential for identifying the elements and compounds present in a sample and how they are organised at the molecular level.

We use advanced techniques such as infrared spectroscopy (FTIR), atomic absorption (AAS), X-ray fluorescence (XRF) and nuclear magnetic resonance (NMR) to analyse the composition of raw materials. These tests allow us to verify the purity of compounds and detect contaminants.

For example, at INFINITIA, we use techniques such as FTIR infrared spectroscopy, gas chromatography (GC-MS) and liquid chromatography (HPLC-MS) to identify unknown additives in technical polymers intended for automotive components, ensuring that customer specifications are met.

Microscopy tests and morphological analysis

Microscopy testing is crucial for observing the microstructures of materials and detecting possible defects or irregularities in their internal structure.

We use optical microscopy, scanning electron microscopy (SEM) and atomic force microscopy (AFM) to generate detailed images of the surface and internal structure.

A typical case is the identification of microcracks and defects in welds for the electronics industry, using SEM to study surfaces after different processes and optimise welding parameters to prevent failures.

These tests allow us to evaluate how raw materials behave under mechanical stresses such as traction, compression, torsion or fatigue.

At INFINITIA, we perform hardness, resilience, elastic modulus and impact resistance tests in accordance with international standards such as ISO and ASTM.

A common example is the validation of plastic housings, where we perform drop and impact tests to determine the durability of parts under real-world conditions and thus ensure structural integrity and safety.

Thermal analysis measures how a material reacts to temperature variations, which is crucial for determining its thermal stability.

We use techniques such as differential scanning calorimetry (DSC), thermogravimetric analysis (TGA) and thermomechanical analysis (TMA) to evaluate the glass transition, mass loss and thermal resistance of materials.

For example, in the development of new electrical insulation materials, we apply TGA and DSC to ensure that a polymer maintains its properties, guaranteeing its performance under extreme conditions.

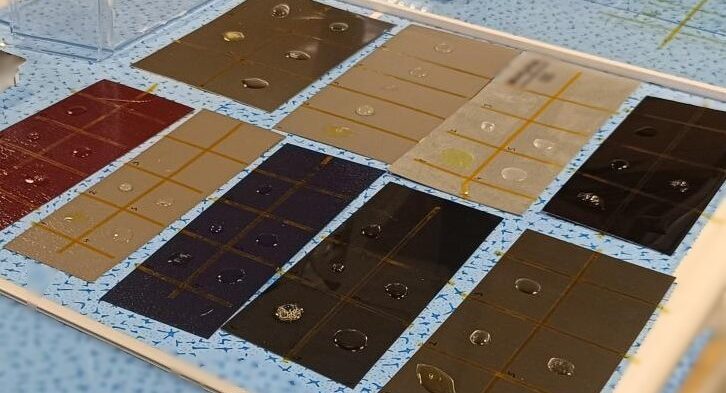

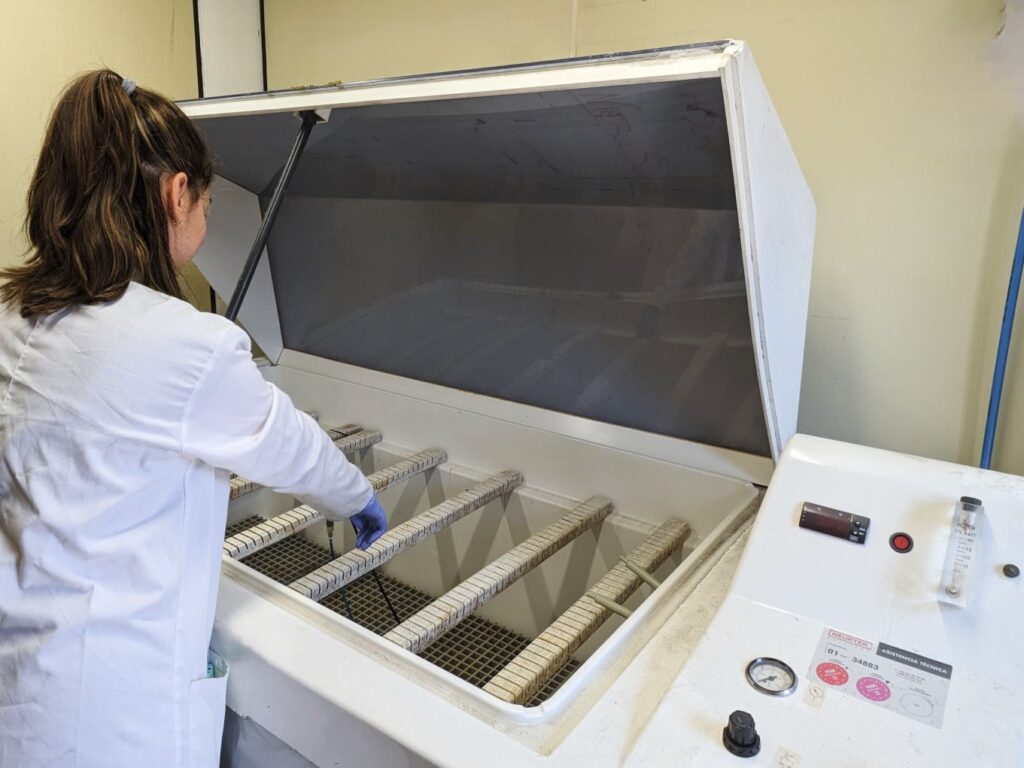

These tests simulate extreme conditions to predict the durability of materials against factors such as corrosion, humidity and ageing.

We use salt spray methods, climatic chambers and electrochemical tests to evaluate oxidation resistance and long-term behaviour.

An example of this application is the comparison of metal coatings, subjecting them to extreme humidity and temperature conditions to select the most resistant option to oxidation. This allowed the manufacturer to select different material qualities according to the product range and thus optimise production costs.

Using gas chromatography (GC-MS) and liquid chromatography (HPLC-MS) techniques, we analyse the migration of compounds and residues present in materials.

These tests are essential in sectors such as food packaging and medical devices, where safety is a priority.

At INFINITIA, we have used GC-MS to measure the presence of volatiles in different components subjected to certain operating conditions, in order to determine the maximum TLV values and select the optimal material for that application.

Applications of the definition of raw material quality parameters

The definition of raw material quality parameters has crucial applications in many industrial sectors. Through physical, chemical, thermal and mechanical testing, at INFINITIA we help to validate products, select raw materials and anticipate possible failures under real conditions of use.

Below are some of the sectors where this service is key:

Automotive industry

In the automotive industry, the materials used must withstand vibrations, mechanical loads and extreme conditions. The characterisation of materials allows us to select lightweight, resistant and durable solutions for structural components, plastic housings, metal coatings or parts subject to fatigue.

We are able to define parameters for:

- Impact resistance and thermal stability in plastic housings, by validating their behaviour under thermal cycles and impacts in extreme conditions.

- Corrosion resistance in metal coatings, through salt spray tests that allow the most durable option to be selected for aggressive environments.

Food industry and packaging

The materials used in food packaging must guarantee food safety and preserve the properties of the product. The characterisation of materials validates thermal resistance, barrier behaviour and possible migration of substances, complying with European and sectoral regulations.

We define quality parameters using:

- Contaminant migration tests on food packaging using chromatography (HPLC and GC) to ensure food safety and compliance with European and industry regulations.

- Thermal analysis of films to validate their resistance to pasteurisation processes.+

Medical devices

Medical materials must withstand sterilisation processes, maintain dimensional stability and not release toxic compounds. The characterisation of materials guarantees the safety, functionality and service life of polymers, coatings and implantable or disposable parts.

We help define parameters for:

- Thermal stability of polymers for use in steam or gas sterilisation, guaranteeing their functionality.

- Chemical purity in medical devices, using liquid chromatography (HPLC) aimed at detecting residues to ensure patient safety.

Energy and electronics sector

In electronic and energy systems, materials must offer thermal stability, dielectric strength and predictable behaviour under load cycles. Characterisation ensures their reliability in encapsulants, insulators and components for power electronics or electric mobility.

We help define parameters for:

- Dielectric strength of insulating ceramics used in batteries and power systems to ensure their performance under load cycles

- Thermal stability in encapsulants for electronic circuits, using techniques such as DSC and TGA, to determine their maximum operating temperature.

Construction industry

Construction materials must retain their structural integrity in the face of moisture, loads, abrasion and chemical agents. Material characterisation allows us to anticipate their long-term behaviour and validate solutions in accordance with technical regulations and environmental requirements. We help define quality parameters through:

- Accelerated ageing tests on facade panels to evaluate their response to moisture and UV radiation.

- Measurement of surface wear and abrasion resistance of industrial flooring.

Technical textiles and functionalised materials

Technical textiles and functionalised surfaces must maintain properties such as fire resistance, antimicrobial effect and thermal comfort. At INFINITIA, we characterise these materials to validate their effectiveness and durability under real conditions of use. We support you in defining parameters through:

- Tear and fire resistance tests on technical fabrics used in workwear.

- Analysis of antimicrobial coatings applied to hospital uniforms through microbiological tests for bacterial growth inhibition.

Guaranteeing excellence in the selection of raw materials

At INFINITIA, the precise definition of raw material quality parameters is essential to ensure the reliability, durability and performance of products in various industrial sectors.

Through our advanced testing and state-of-the-art equipment, we help companies select the most suitable raw materials for each application, ensuring compliance with the most stringent international regulations and quality standards.

The benefits of this service are numerous: from optimising production costs to reducing the risk of premature failure in end products. By anticipating and preventing problems throughout the manufacturing process.

INFINITIA contributes to improving efficiency, safety and customer satisfaction. Our ability to perform customised testing tailored to the specific needs of each customer ensures that the materials selected are the most suitable for each application and that their properties are best suited to the environment in which they will be used.

As industrial sectors continue to evolve, the role of material characterisation and the definition of quality parameters will remain crucial. Technological innovations will continue to provide new opportunities to improve materials and manufacturing processes.

With INFINITIA, companies can be confident that they have a reliable partner to ensure the quality of their products and comply with industry standards.