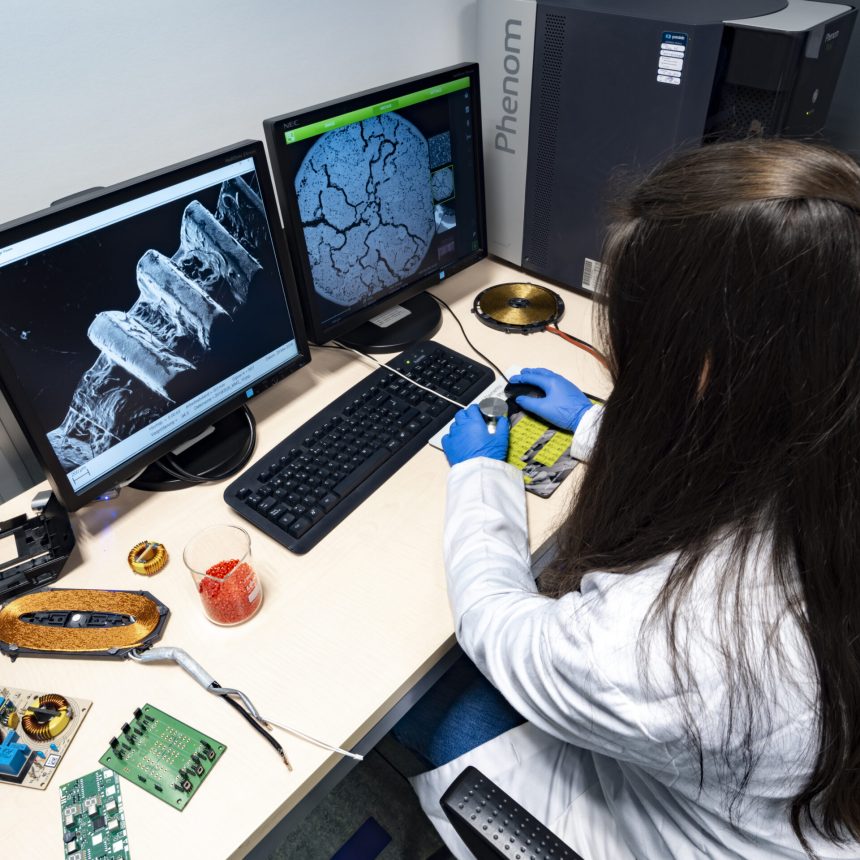

Fractography and microscopy tests

At INFINITIA, we research and carry out failure analysis of materials. Therefore, we are experts in fractography and microscopy testing. We study fracture surfaces and provide a detailed analysis of the conditions that caused the breakage. In addition to our experience and knowledge, the use of advanced techniques such as the scanning electron microscope (SEM) allows us to examine microscopic features that are not visible to the naked eye.

With our analytics, we help companies like yours identify failure modes and improve product design and performance. Find out what we can do for you.

What is fractography?

Fractography is the study of the fracture surfaces of materials, which is used to determine the causes and modes of failure. In the INFINITIA laboratory we analyze the characteristics and patterns that form on the fracture surface to identify whether the breakage was caused by a brittle fracture, ductile fracture, shear fracture or fatigue fracture. These analyses are key to preventing future failures and optimising materials and manufacturing processes in sectors such as the automotive, aeronautics and construction industries.

Contact with us

Contact us for more information or, if you prefer, you can use one of our other technical consultancies with complementary services to boost your project.

Types of fractures in materials

Brittle fracture

It is characterized by rapid failure without appreciable plastic deformation. Materials that fail in a brittle manner usually break suddenly when a critical stress is reached, and without prior warning.

Brittle fracture analysis shows flat, shiny surfaces, often with conchoid patterns similar to those seen in glass fracture. This type of fracture is common in ceramic materials or metals at low temperatures and can be dangerous in critical applications, as lack of pre-failure deformation can lead to catastrophic failures.

Ductile fracture

In this type of fracture the material suffers considerable plastic deformation before breaking. Analysis shows rough surfaces with cavities and stretch marks indicating that the material was able to absorb energy before failing. This behaviour is preferred in many industrial applications as it provides visible signs before failure, which in turn allows preventive measures to be taken.

In addition to brittle and ductile fractures, our analyses also evaluate other failure modes such as shear fracture and fatigue failure.

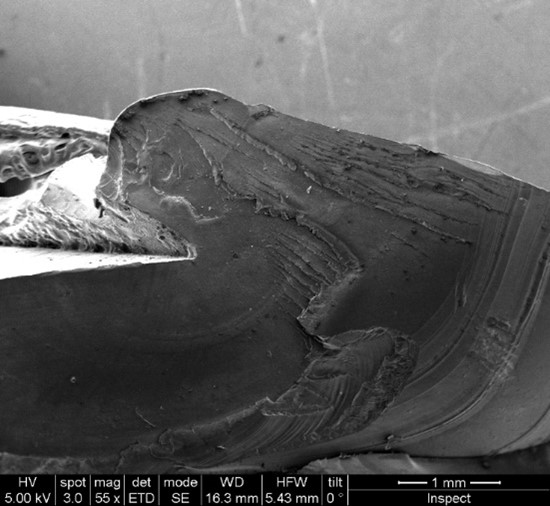

Shear fracture

A shear fracture occurs when the material breaks due to shear or sliding forces in parallel planes. In fractographic analysis, fracture surfaces often show striations or step-like marks; indicating that shear stresses were responsible for the failure. This is common in applications where materials are subjected to torsional loads or shear stresses, such as in machine shafts or components subjected to multi-directional stresses.

Fatigue fracture

Fatigue fracture occurs when a material is subjected to repeated cycles of loading and unloading, even if the applied stresses are below the breaking limit of the material. Fatigue fracture is a dangerous phenomenon because it develops slowly, over time, and can go unnoticed until the material fails completely.

In our tests we use an electron microscope to identify the characteristics of a fatigue fracture, such as beach marks and striations, which indicate how the crack propagated before total failure.

Electron microscopy: what it consists of

The use of electron microscopy is essential in failure investigation, as it provides us with critical information about the behavior of materials at a microscopic level. This level of detail helps us improve our customers’ designs and select materials that are more suitable for their applications, preventing future failures.

To perform detailed analyses of fracture surfaces, we use various microscopy techniques, as well as the electron microscope: an advanced tool that allows us to examine the microstructure of materials with great precision.

Through this type of microscopy, we can observe details at a microscopic level that would not be visible using conventional optical techniques. For example, observing fracture surface features such as fatigue striations, conchoid patterns in brittle fractures, and cavities in ductile fractures.

Why are fractography tests important in failure prevention?

Thanks to fractography and microscopy tests, we prevent future failures in industrial products. This involves a detailed analysis of fractures, which helps us to identify weak points in materials or manufacturing processes, facilitating the implementation of improvements. We increase product durability, reduce the risk of failure and optimize production costs.

We know the causes of failure and can therefore improve materials, manufacturing processes or even operating conditions. This is crucial in sectors such as aeronautical engineering and automotive, where a brittle fracture or fatigue failure can have serious safety consequences.

In addition, fractography testing can pinpoint potential design or manufacturing issues that are not detected by standard tests, providing a detailed and accurate view of how materials fail under real-world conditions. This information is essential for optimizing product life and improving long-term performance.

Benefits of fractography and microscopy testing at INFINITIA

Why choose this fractography and microscopy testing service from INFINITIA? Here are some of the main reasons:

- Precision and detail: We employ advanced and innovative techniques to provide a detailed analysis of fracture surfaces and thus determine the exact causes of failure. We did this, for example, with this failure analysis of flexible circuits and electronic components.

- Professionalism and rigor: We are specialists in fractography and microscopy. Scientists from different branches who combine experience and knowledge. We always work with rigor and professionalism.

- Failure prevention: We prevent future failures in companies, thanks to early identification of materials and manufacturing processes. An example is this case of reverse engineering of metal waste, where the origin of said waste could be determined.

- Product improvement: We optimize both the product design and the processes that encompass it. We increase the durability and reliability of the materials used. An example? This success story about the detection of defects in paints by microscopy.

Implementing electrochemical testing early in product development significantly reduces development times, improves product durability and reliability, and ensures optimal performance in harsh environments. Contact us and let us know how we can help you.

We are specialists in fractography and microscopy tests

INFINITIA’s fractography and microscopy testing is present from the earliest stages of new product development. The aim is to identify potential failure modes from the earliest stages of design in order to improve the product, save costs and reduce risks.

Because we know that there is no better guarantee than a job well done. We are specialists and we work with the latest in media and methodologies. Write to us and together we will see how to improve your project.

Contact us, contact INFINITIA

Do you need specialized services in fractography or electron microscopy analysis? At INFINITIA Industrial Consulting we help you improve the quality and reliability of your product. We ensure its success in the market!

Contact with us

Contact us for more information or, if you prefer, you can use one of our other technical consultancies with complementary services to boost your project.