Homologation tests

Homologation tests are those in which we evaluate the physicochemical properties of materials (such as metal, glass, plastic or paints) and component functionality, facing validate whether they meet the technical requirements of the product in which they will be used.

The homologation tests allow us they allow obtaining reference values of the key parameters of the material or the part, that allow us to predict their behavior during the product’s life cycle, it is possible to optimise raw materials in terms of functionality and cost in the final component, as well as document their quality in the event of market failures; using this as an argument in claims to the raw material supplier.

We analyze and evaluate the properties of materials and components taking into account the product’s service conditions and the failure modes that may occur. At INFINITIA we are specialized in homologation of materials and components. Find out how get unique pieces that are fully adapted to your industry.

Materials homologation test. What is it for?

We optimize the costs and durability of the parts. The homologation tests of a raw material help us to know which material and with what characteristics should be used in a specific part, as well as to validate more economical alternatives that meet the same requirements. We select the materials by checking their mechanical properties, their resistance to corrosion or wear, among others.

From scientific rigor, we characterize the materials and evaluate them according to current standards at an international level and those specific to the sector or region of interest, taking into account the service conditions of the part in which the materials to be approved will be used. These approval tests also allow us to anticipate the failure mechanisms that may arise, detecting the critical parameters of the material itself and allowing changes in the design of the components that prevent failure.

Contact with us

Contact us for more information or, if you prefer, you can use one of our other technical consultancies with complementary services to boost your project.

In which sectors are they applied?

While it is true that the approval of materials is important for any industrial sector, in automotive, where vehicle quality and safety standards are very strict and severe; the correct definition and execution of this process is essential. That is why homologation at both raw material and component level is very common in this sector.

However, at INFINITIA we carry out approval tests for all types of companies. And that is because manufacturing industries in the domestic appliance industry, where mass production is involved, it is essential to optimise costs without compromising quality. Material approval tests are therefore in high demand.

Specific homologation tests at INFINITIA

In addition to carrying out approval tests of materials and components according to regulations, if necessary, at INFINITIA we carry out specific approval tests or customised tests. We adapt to you and not the other way around. Contact us and together we will see how we can help you define an approval process that meets the specific requirements of your products.

We analyse all the details, because we are specialists in Forensic Engineering. We are prepared for failure mechanisms and can anticipate them. We work under the protection of knowledge and experience, as well as with thoroughness and rigour, providing this added value to focus on what will be critical in the material and the part.

Advantages of a homologation test of parts or components

Once the product requirements are known, we help you choose the most suitable materials for each component. In addition to being able to approve the product according to current regulations, approval tests allow us to choose the optimal material for its manufacture.

We save companies time and costs, as we anticipate failure mechanisms. Thanks to this INFINITIA service, we can anticipate possible future problems or failures by optimizing materials for their applications.

Another advantage of this type of tests that we carry out in our laboratory is the approval of new suppliers. Through this process, we advise you to jointly search for new suppliers that fully meet your needs. Find out more now!

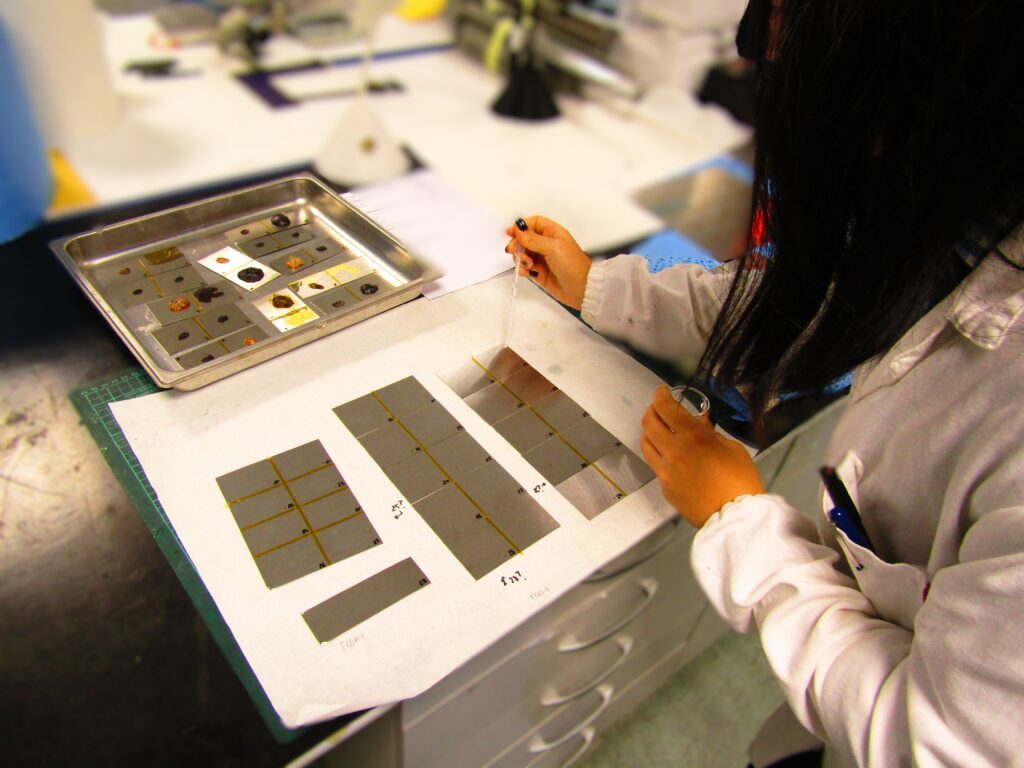

Examples of our homologation testing work

INFINITIA is your homologation laboratory. We are experts in the approval of materials and components, through the definition and execution of different validation tests.

Below are some examples of homologation tests that we have carried out:

In this case, using Reverse Engineering we analysed the properties of a steel so that our client could decide on the search for a new supplier for its parts with high technical requirements.

For this work, we adapt and apply the relevant standards for the sector to set up a suitable testing environment, and evaluate the behaviour of these materials under adverse humidity conditions. In this way, we ensure the quality and reliability of the insulating materials.

To achieve a more resistant and safe product, it is necessary to carry out this type of approval tests, which allow us to know the durability and reliability of the components and materials in the face of extreme thermal variations without suffering significant damage.

In this case, the products to be approved were surgical implants. The approval of these materials had to be done under the ISO 10993-1 standard in order to guarantee their safety and efficacy for clinical use. The Forensic Engineering team not only carried out approval tests on the materials, but also reviewed the manufacturing and sterilization processes of the implants.

Contact with us

Contact us for more information or, if you prefer, you can use one of our other technical consultancies with complementary services to boost your project.