Testing of electronic components

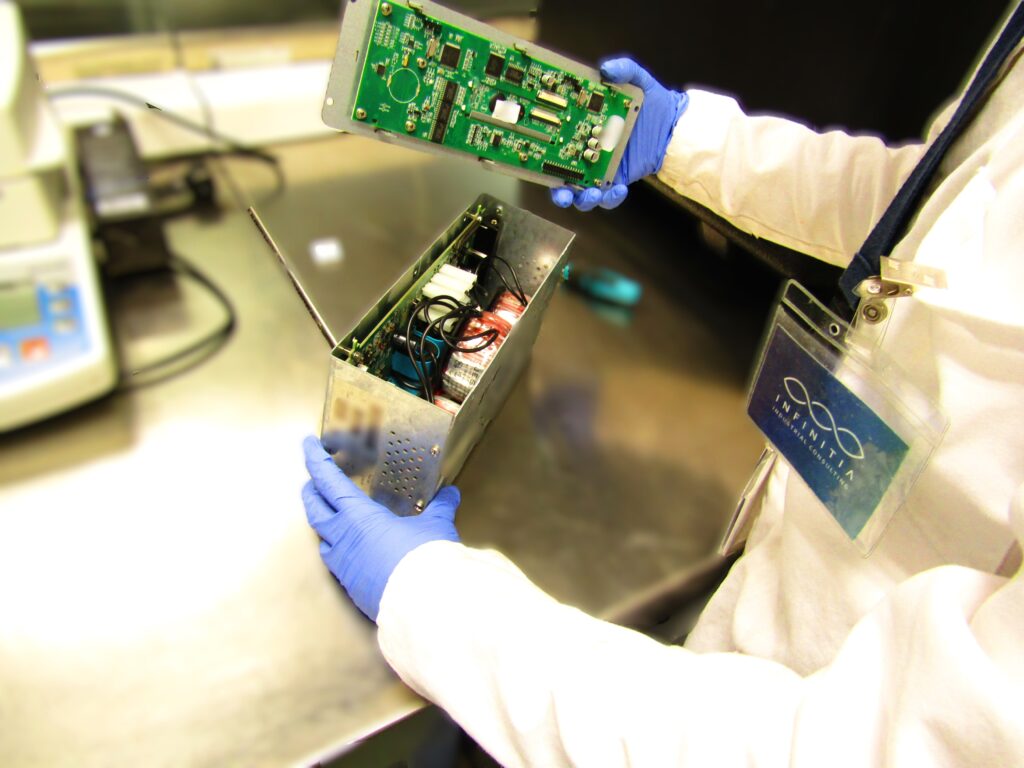

A guarantee of quality and safety in electrical and electronic products. That is the goal we set ourselves from Infinitia’s laboratory, where we carry out a wide variety of tests on electronic components.

We measure the performance, resistance or durability of electronic components, through different analysis methodologies. Discover what we can do for your business.

What is the testing of electronic and electrical components at Infinitia?

We perform different types of tests for electronic and electrical components, which allow us to provide solutions to our customers to create the most reliable parts in the market. We adapt to the different needs of each one of them, so that we can even carry out customized tests.

It doesn’t matter if the elements are complex, of large dimensions or have difficult geometries. In Infinitia we are qualified professionals and we want to help you.

Electronic component testing services

These are the different testing services for electronic and electrical components that we carry out in Infinitia’s laboratory. Discover them below:

Carrying out IP tests allows us to check the degree of sealing of electronic components against liquids such as water or solids such as dust, among others.

Cell phones or watches are usually the type of electronic product that requires this type of testing. These products consist of a casing and an electronic element and require water resistance.

Corrosion or extreme environments

Corrosion causes wear of a multitude of elements, especially metals. Metals which, on the other hand, are one of the main electronic components. Hence the importance of this type of test.

We check the degree of corrosion resistance of the different electrical and electronic components, in order to improve their quality and, consequently, to guarantee safety and quality in the parts as well as to save costs.

Temperature or thermal shock

We perform radical temperature changes to electronic components. The objective is to weigh different scenarios, always maintaining the quality of the parts. To do this, in our Infinitia laboratory we use, compared to conventional climatic chambers, specific machinery that allows us to subject the parts to very abrupt temperature changes, and in an instantaneous way.

In this way we analyze the thermal properties of electrical and electronic products, as well as their aging.

Reverse engineering

We reverse engineer the manufacturing process of electronic and electrical parts and equipment down to the electronic components to improve their performance. Reverse engineering allows us to detect counterfeits in components or electronic parts such as microchips.

We analyze in detail the different components and discover their technological principles of design and manufacture.

Failure analysis

We apply forensic engineering to the testing of electronic and electrical components. And one of its methods is failure analysis. This allows us to check the failures in the different types of soldering, as well as to observe and check if the plastic components or the metals that are part of these electronic and electrical products are of lower quality, etc.

In our electronic components testing laboratory we perform a rigorous quality control on the components. We perform an analysis of the failures to prevent their recurrence.

Contamination during the manufacturing process

Within the testing of electronic components, it is very important to perform an analysis of contaminants. If the environment where the different manufacturing and production processes are carried out is not controlled, it is very easy for external factors to contaminate the parts, causing their failures.

Moreover, in our laboratory, we are aware of its importance. Contamination of components can affect quality standards and regulations.

Component homologation

At Infinitia, we are also your technical consultancy. We provide real solutions adapted to every business need; being one of the most demanded services the homologation of components.

With this, we give you the keys to avoid counterfeit electronic components, as well as to offer you other suppliers. Alternatives that adapt perfectly to the circumstances of your business and that allow you to create electrical and electronic products with total security.

To whom they are addressed

We avoid defective materials, guaranteeing the quality of electronic components. For this reason, many electronics manufacturers or assembly companies rely on Infinitia, among other organizations in the sector.

Our laboratory, in addition to being equipped with the latest cutting-edge technology, is formed by a team of professionals. Therefore, we offer all our experience and knowledge during the testing of electronic and electrical components. Our mission is to provide each of our customers with excellent work, so that they continue to trust us.