Tests on glass, enamels and ceramics

One of the types of analysis we carry out in the Infinitia laboratory is testing glass, enamels and ceramics. Tests where we measure chemical and physical resistances of these materials, with the aim of create products with optimal components.

These resistance tests and chemical characterisations are not only functional, but also have an aesthetic purpose. Do you want to know more? Find out more now with Infinitia.

What is a glass, enamel and ceramic test?

We employ both physical and chemical tests to create a highly resistant glass or ceramic. And in these tests on glass, enamels and ceramics we measure material properties such as resistance, physical and chemical abrasion, hardness, scratching or acid-base resistance.

Thus, physical tests allow us characterize the coatings of glass, enamels and ceramics; while in chemical tests we analyze compatible materials. This is the case of silkscreen printing, which we check with these tests if there are defects caused by the interaction with basic or acidic compounds, as well as identifying possible aesthetic defects or wear failures.

Do you have any questions about this? Please contact us without obligation.

Contact with us

Contact us for more information or, if you prefer, you can use one of our other technical consultancies with complementary services to boost your project.

Types of tests on glass, enamels and ceramics

We carry out the different tests according to standard regulations for glass, enamels and ceramics. However, at Infinitia we seek to go further. We carry out usage tests, we certify the resistance of materials and we adapt these types of tests to the consumer’s conditions of use. We have a proactive approach to our work.

Below are some examples of products that require our glass, enamel and ceramic tests:

- Glasses: That require an anti-dirt or anti-reflective treatment, for example.

- Coatings: With anti-fog properties, anti-limescale, anti-dirt or antiscratch, among others.

- Functional ceramics: Those intended as insulators. This is the case of the electrical industry.

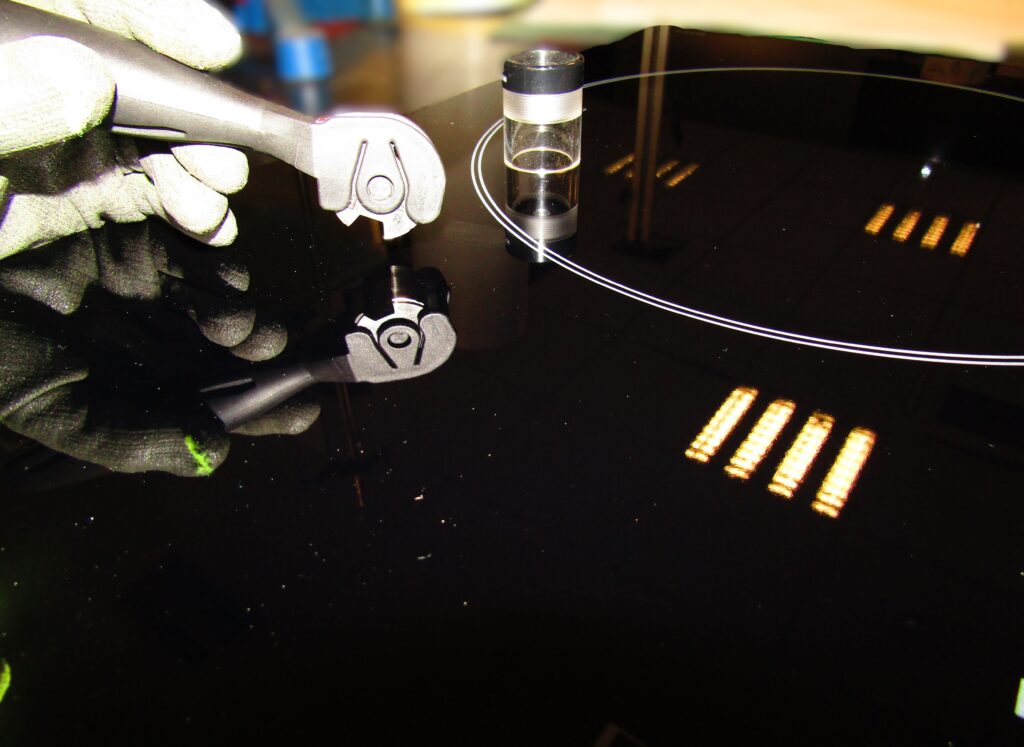

- Systems or new product development lines. for example the improvement of enamelling processes by induction heating.

What are the advantages of testing glass, enamels and ceramics?

The main task of these tests on glass, enamels and ceramics is to achieve that the materials have optimal characteristics, which means the longest possible service life. Thanks to these analyses, we are able to improve the resistance of the glass or ceramic; which allows the customer to experience less wear on the material and, therefore, the product made with these glass ceramics lasts as long as possible without being damaged.

Infinitia’s work is also synonymous with safety for manufacturers. Our clients have a full guarantee for their own clients or end consumers. With our tests on glass, enamels and ceramics we ensure that the material is in perfect condition, avoiding possible damage or accidents.

In which industries are glass, enamel and ceramic testing applied?

These tests on ceramic materials and glass can be applied to various industries. Firstly, to the household appliance industry, where there is a large presence of ceramic glass. For example, in the manufacture of a glass ceramic. In this type of product, at Infinitia we measure both the chemical and physical resistance of its components. Likewise, in the construction industry are also important.

On the other hand, these tests for ceramic and glass products are interesting for manufacturers of glass surfaces or even for bottling glass manufacturers. And despite being different types of glass, they must also be created according to regulations.

At Infinitia we have experience in testing glass, enamels and ceramics.

Our team of experts in materials innovation is made up of specialists in mechanical and chemical engineering. This cross-disciplinary approach allows us to not only provide solutions to our clients’ demands, but to go one step further.

For this purpose, these tests on glass, enamels and ceramics are carried out with cutting-edge equipment and methodologies. Thus, among other means, in our Infinitia laboratory we have an optical microscope and an abrasimeter for analysis of physical and chemical resistance of glass, enamel and ceramics; even going through the scanning electron microscope (SEM).

And if you want to know more about our work, here is a success story about glass testing:

New materials through modifications to the surface finish of glass: Through laser texturing we make glass easier to clean, as well as providing it with antibacterial properties to achieve a cleaner and more hygienic product.

Contact with us

Contact us for more information or, if you prefer, you can use one of our other technical consultancies with complementary services to boost your project.