Thermal properties

What are the thermal properties of materials? Why is it that materials such as steel are chosen for the design of a given product and wood is not considered? Thermal properties are present in all product development, since the most diverse parts will have to face requirements such as being subjected to intense heat for a short period of time or, on the contrary, resisting temperature changes outdoors for a long period of time.

Indeed, when heat is supplied to a solid, liquid or gaseous body, some of its properties change. Thermal characteristics are associated with a material-dependent response and basically all material properties(physical, chemical, mechanical, electrical, magnetic and optical) are temperature-dependent, although there are materials specifically designed to resist extreme heat.

Among the thermal characteristics we find some related to heat transport (thermal conductivity, thermal diffusivity, heat capacity…), phase changes, such as first order transitions (boiling and melting), or physical properties, which are altered when a body is subjected to a heat source.

If you need to perform tests to check the thermal properties of materials, in Infinitia Industrial Consulting we offer you the possibility to perform high precision tests, with the most qualified personnel, who will analyze aspects such as melting temperature or thermal stability.

Types of thermal properties

Some of the most important thermal characteristics of materials in engineering, such as heat capacity, thermal conductivity, thermal expansion, fusibility and weldability, are as follows:

1. Heat capacity

Heat capacity is a property that indicates the ability of a material to absorb heat and change its temperature, thus measuring the external energy required to increase one unit of temperature. In mathematical terms, heat capacity (C) is the rate of change of heat (Q) with respect to temperature (T):

C= dQ ÷ dT

In practical terms, heat capacity expresses the greater or lesser difficulty a body has in undergoing change when exposed to heat. For example, the heat capacity of the water in a swimming pool will be much greater than that of a glass of water, which we can easily heat in a microwave oven.

This should not be confused with the concept of specific heat (represented by the lower case c), which refers to the heat capacity per unit mass. Thus, this capacity of a body to “store heat” is the quotient between the heat capacity and the mass of the object. The unit of specific heat in the International System is J/(kg∙K). Thus, it is possible to calculate the amount of heat in joules needed to increase the temperature of a given kilo of substance by 1 degree.

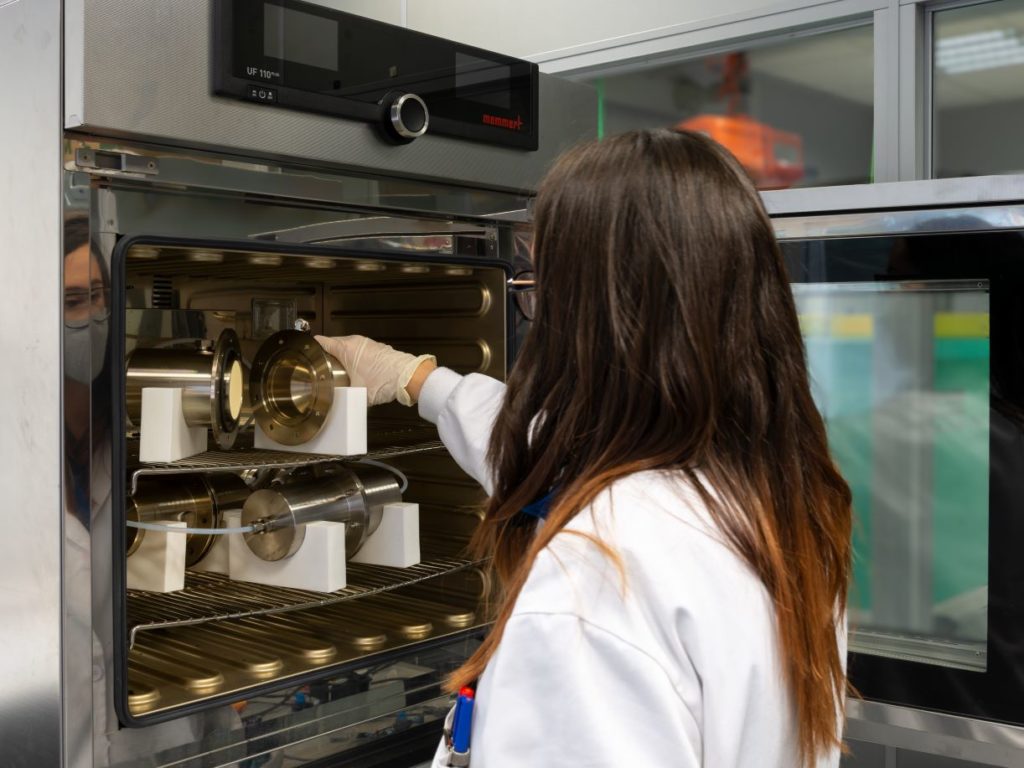

Product development cannot overlook thermal properties and one of the tests performed on materials to determine their aging is to subject them to a climatic chamber that mimics the behavior of a material over a period of 0 to 10 years under defined climatic conditions.

Here you can see a practical example of its use in the accelerated aging of materials to detect critical corrosion failures.

2. Thermal conductivity

Thermal conductivity is the ability of a material to transfer heat. Thermal conductivity is expressed in International System units as W/(m∙K). Metals, which are so capable of being extremely hot or icy, do not boast the highest thermal conductivity; diamond does. It is followed on the list by silver, copper, silicon carbide, graphite, iron and steel.

The reason is that the atoms of metals have free electrons in the outermost layers, something that allows them to move easily and transport thermal energy (as happens with electricity). This is not the case with many plastics, insulating materials or, for example, wood. It is therefore never a good idea to cover radiators with furniture.

3. Dilatation or thermal expansion

Most materials expand when heated and contract when cold. Thermal expansion of materials represents their expansion when heated. It can be in length, volume or some other metric dimension. It can be measured in different ways such as:

Linear dilation: when variation in a single dimension predominates.

Cubic expansion: the coefficient of volumetric expansion compares the value of the total volume of a body before and after the temperature change.

Area or surface dilation: when the body increases its dimensions in the same proportion.

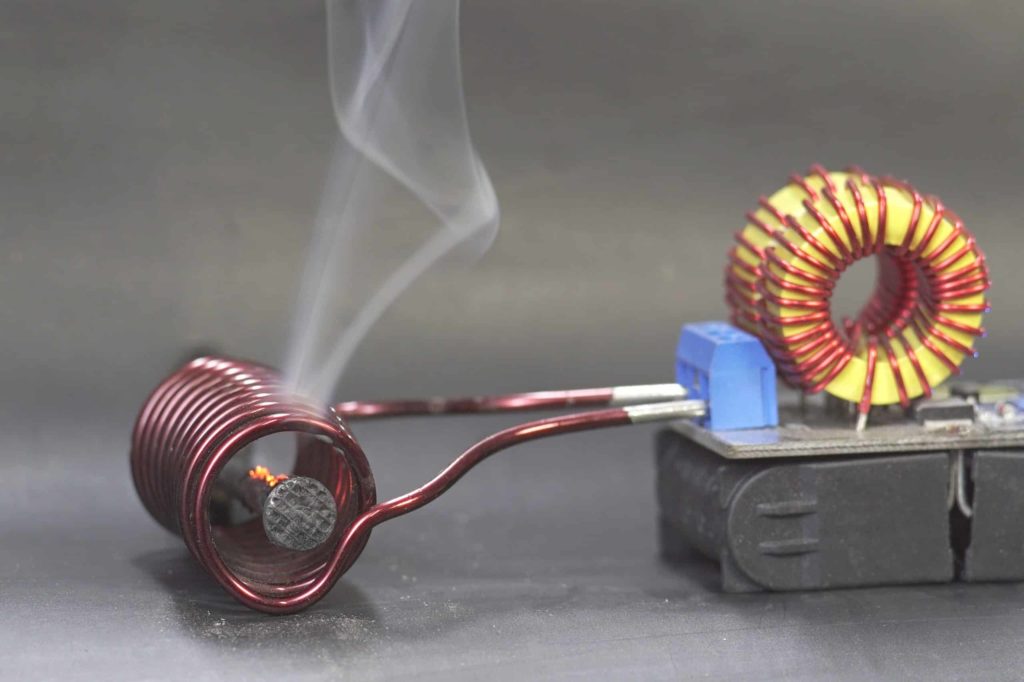

4. Fusibility

Meltability is the ease with which a material can melt or fuse. It is clear that some materials, such as metal, glass or plastics melt easily when heated, but this is not always the concern when selecting materials for a product.

Knowing this ease or resistance to melting is essential for processes such as soldering, where the alloy used for soldering must have a low melting temperature compared to the materials to be soldered. For soft soldering, lead and tin alloys are usually used, while for hard soldering, materials such as silver, copper or zinc are used.

On the other hand, there are refractory materials – which can withstand high temperatures without decomposing – such as aluminum, silicon and magnesium oxides, which are used in smelting furnaces and incinerators.

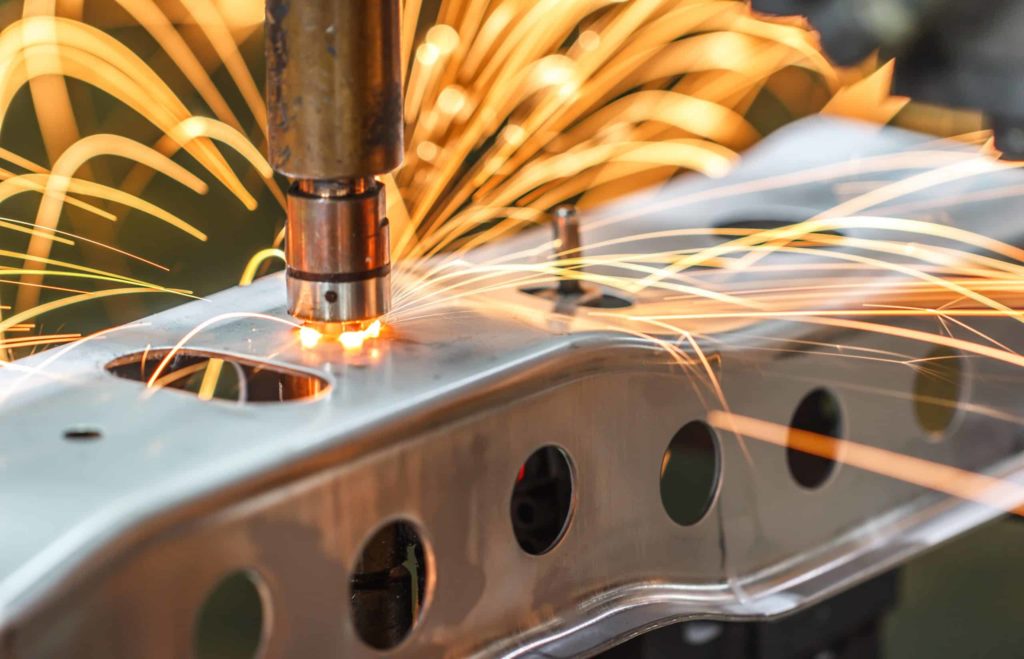

5. Weldability

It is the ability of one or more materials to adhere two of its parts with a homogeneous and quality weld, so that they meet the needs for which they were designed. It can be done by applying heat until the melting temperature is reached or by using an intermediate material for its adhesion. Steel, aluminum, nickel, copper or titanium and their alloys are metals that are commonly used for welding.

In this practical example, through material innovation, the Infinitia team solved the challenge of finding the ideal material for sustainable corrosion-resistant coatings, which also had high temperature, high humidity, weld-compatible and cost-effective requirements.

Contact with us

Contact us for more information or, if you prefer, you can use one of our other technical consultancies with complementary services to boost your project.

Materials testing and analysis: Thermal stability and melting temperature

Having seen the main thermal properties of materials, in this section we will study two of the main tests in this field, thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC).

Thermal stability (TGA)

Thermogravimetric analysis, known by the acronym TGA, is one of the most popular tests in the manufacturing and materials industry, as it allows to approach different compositions, from metals to polymers, glass and ceramics.

This is a thermal analysis method in which the mass of a sample is measured over time as the temperature changes. It is used to analyze material characteristics and composition, decomposition and evaporation rates, oxidation, material purity and other properties.

Among its main uses is the measurement of the thermal stability of a material. In this sense, thermogravimetric analysis will subject a product to the range of temperatures to which it will be exposed during its use, in order to ensure that it meets expectations during its normal application.

Melting temperature (DSC)

Differential Scanning Calorimetry (DSC) is another thermal analysis technique, in this case, focused on studying the effects of temperature on the variation of the heat capacity (Cp) of a given material. For this purpose, a sample with a specific mass will be subjected to cold and heat, in order to observe the changes caused by temperature variations in its heat capacity.

With this technique it will be possible to identify, for example, transitions such as those related to the melting point or melting temperature, which is when a material changes its state from solid to liquid.

In Infinitia Industrial Consulting we are experts in materials and we help dozens of companies and organizations to solve specific problems from this approach. Contact us for more information.

Contact with us

Contact us for more information or, if you prefer, you can use one of our other technical consultancies with complementary services to boost your project.