The performance of the products being marketed must be tested during the prototyping phase to avoid possible future failures. In this sense, if a car brand announces the sale of a new type of steering wheel, before bringing it to the market it will be necessary to check that there will be no short- and long-term problems in its use. The same applies to brands of furniture, household products, kitchen and bathroom materials and a wide range of articles from all possible sectors.

From Infinitia’s Prototyping team, we prepare a prototype or improve it for its industrialization, both those already on the market and those new ones that are being developed. Therefore, in this article we explain what this service consists of and our working method.

In coordination with the Forensic Engineering department, our role is to investigate mechanically, chemically and electronically to test all aspects that influence a final product to obtain an optimal result. “When we receive a new prototype, we establish a correct or expected performance and, from there, we start testing it to find out the faults and be able to offer a solution,” explains Rubén Gotor, Quality Specialist at Infinitia.

The types of tests are diverse. They can be tested for wear resistance, deformation of both plastic and metal parts, operation in different environments, transport, connectivity (whether it is connected via wifi or Bluetooth), chemical resistance…

Regarding the latter, Javier Sanz, our CEO, points out: “Materials have a theory of greater or lesser resistance, but it always has to be checked. Before launching a product that is going to be placed in a kitchen or a bathroom, for example, it is necessary to carry out a test. In other words, a detergent or degreaser test – to continue along the same lines – must be carried out to validate the functionality of these devices. If the material does not withstand bleach, we need to find one that does.

These tests of life and operating circumstances are recreated in a limited space of time. “You have to get the failure that occurs in years, in a week or in a day,” notes Gotor. “Every possibility, we accelerate it. We reproduce real conditions on a laboratory scale.” In this way, the processes are repeated continuously until the desired result is reached.

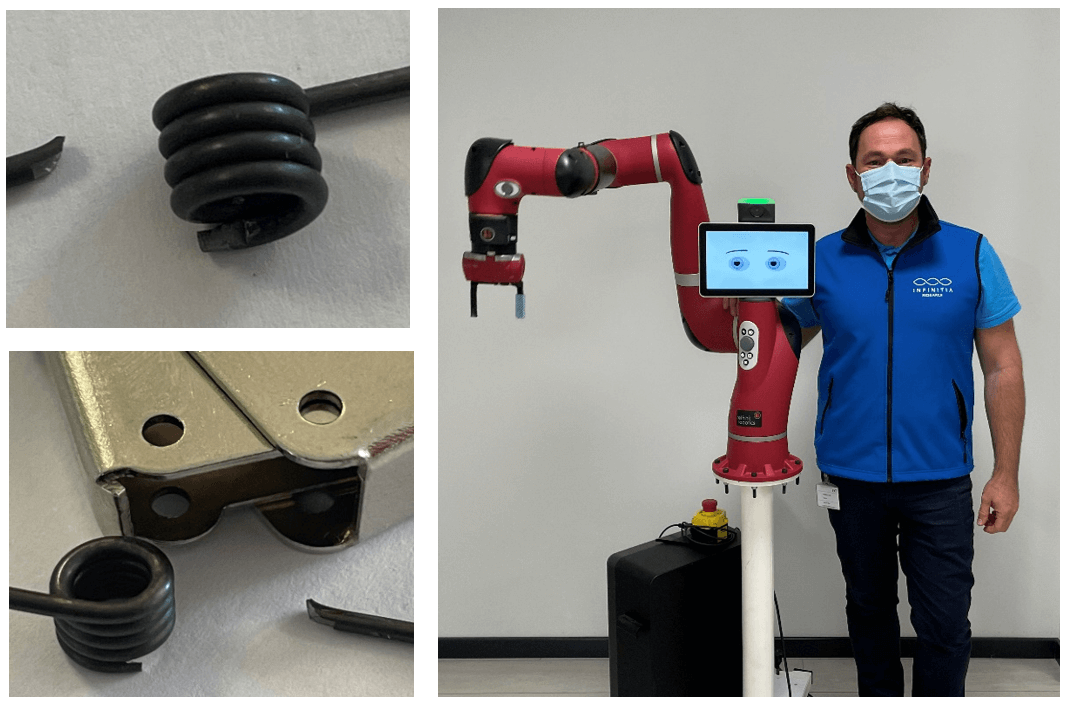

“Our most recent project was to test the opening system of a machine, as problems had been detected in its components. The opening and closing mechanism had an aluminum alloy lever that had cracks in its construction. By repeating the same cycle endlessly and testing the same part from different suppliers, we were able to achieve a ranking of the best to be able to give it the go-ahead,” says Gotor. “However, before that, we detected that some parts were breaking at cycle 0 and others at cycle 500. With a programmable robotic arm, we put the device into operation during phases of 3,500 cycles, having established the optimum figure for those that exceeded 11,000 cycles,” he concludes.

Ultimately, the Prototyping team is able to recreate the lifetime of the potential device in a limited period of time, to detect faults and give the customer an option to remedy them.