Nanotechnology and the development of nanomaterials have had a great impact on the fields of science and engineering, influencing future technologies and improving industrial solutions. In this article we explain what nanomaterials are, how they are obtained and their applications.

What are nanomaterials?

Nanomaterials are materials that are tiny in size and smaller in scale than 100 nm, i.e. up to 100,000 times smaller than the diameter of a human hair.

Nanomaterials can be of natural origin, such as smoke, soot and blood proteins, or they can be man-made. These engineered nanomaterials are designed to achieve certain specific functions, such as increasing strength, chemical reactivity or conductivity. This field of study has exploded in the last decade, as it presents enormous possibilities in engineering, industry, robotics, biomedicine and the energy sector, and occupies a fundamental place in the design of many materials, devices and structures.

Properties of nanomaterials

Nanomaterials can be created from minerals or chemicals and their physicochemical properties are different than when they are micro- or macro-sized. The composition, particle size, shape, surface coatings and bond strength of the particles change. Why?

As the size is reduced at the nanometer scale, the exposed surface area increases, which favors greater interaction between nearby atoms and molecules, leading to various attractions and repulsions that cause surface, electronic and quantum effects, affecting the optical, electrical and magnetic behaviors of the materials. This means that a small amount of nanomaterial can significantly modify and improve the properties of other materials. An example of this are polymers with carbon nanotubes, which make the doped material lighter, mechanically stronger and more functional than a metal.

Classification of nanomaterials

Nanomaterials, as we will see below, are classified according to their dimensions:

Nanomaterials of dimension 0

Nanomaterials of dimension 0 are considered nanoparticles and all their dimensions are within the nanoscale. Fullerenes, inorganic nanomaterials such as gold and silver nanoparticles, nanowires, nanodiamonds or quantum dots (semiconductor crystals) belong to this group.

One-dimensional nanomaterials

Two dimensions are within the nanoscale. This classification includes carbon nanotubes and carbon nanofibers. The latter are applied as additives, for example, in polymer matrices to improve their properties, as well as improve electrical conductivity in adhesives and paints without modifying their rheological properties and prevent corrosion of the materials they coat.

Two-dimensional nanomaterials

One of the three dimensions is within the nanoscale and they are in the form of a sheet. They include graphene, which has great potential for application in different fields such as electronics, nanoparticles and nanocoatings.

Three-dimensional nanomaterials

Materials that have no dimensions at the nanoscale, so that electrons are not confined and can move freely. Within this typology are nanostructured materials, nanoparticle dispersions and multilayers.

How nanomaterials are obtained

Nanomaterials have always existed, but techniques for creating, manipulating and engineering materials at this scale have only been developed in the last few decades thanks to technological innovations, such as the scanning tunneling microscope, which allow work at the nanoscale. So how are nanomaterials manufactured? Mainly, there are two processes:

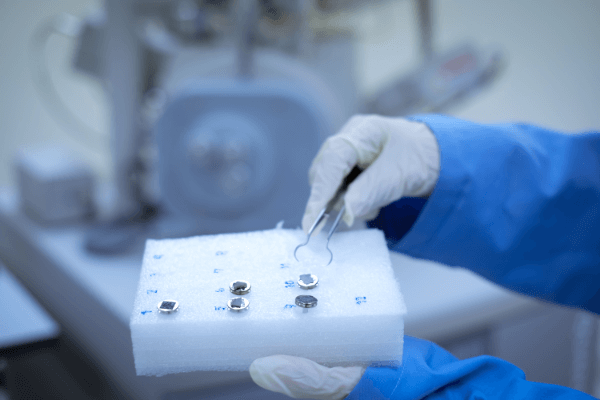

Top-down method or top-down fabrication:

This technique consists in the fabrication of nanomaterials from larger scale materials that are scaled down to the nanometer scale. It starts with large pieces of material and thanks to physicochemical processes they are decomposed until the desired nanomaterial is achieved. Depending on the substance, this process can be relatively simple. Some metallic nanoparticles, for example, can be crushed from microparticles.

Bottom-up or bottom-up manufacturing method:

The second group of fabrication processes involves the construction of nanostructures, atom by atom or molecule by molecule. Despite being more complex, the degree of precision achieved with this technique is greater than that which can be achieved with the previous one, because thanks to microscopes it is possible to place and assemble individual atoms and molecules in a specific place.

Uses of nanomaterials and their technological, innovative and business importance

The use of nanomaterials spans a wide range of sectors, from healthcare and cosmetics, electronics and transportation to environmental conservation and the energy industry. Nanoengineered materials are designed to have increased structural strength, chemical sensitivity, conductivity and improved properties as a whole, generating great potential in materials innovation.

One of the most important applications is offered by carbon nanotubes, a nanomaterial that has the highest strength-to-weight ratio of any known substance, also has higher thermal conductivity than diamond and better electrical conductivity than copper and are extremely light, making them the perfect material for aircraft construction. Similarly, the enormous surface area of carbon nanotubes allows them to be used as electrodes in batteries and capacitors, providing greater electrical and mechanical stability than other materials.

Nanomaterials can also be used as lubricant additives, as they have the ability to reduce friction in moving parts, and even worn parts can be repaired with self-assembled nanoparticles. Advances like this give us more control over the materials we work with, unlocking new capabilities that can change the way we approach forensic engineering problems.

The structures and properties of materials can be improved through these nano-fabrication processes. For example, cooling properties can be improved thanks to nanomaterials or stronger, lighter, durable, water-repellent, anti-reflective, self-cleaning, UV-resistant, infrared-resistant, anti-fog, anti-microbial, electrically conductive, etc. materials can be created and different types of materials such as metal, glass or plastics can be processed. Taking advantage of these properties, current products made with nanomaterials range from tennis rackets, catalysts for refining crude oil to the detection and identification of biological and chemical toxins.

In the bio-health sector, nanomaterials are used for the administration of chemotherapy drugs to directly eradicate cancerous growths. They also offer solutions for diagnosis, thanks to the detection of biomarkers by means of nanoprobes, and provide a breakthrough in genomic studies.

On the other hand, in the cosmetics industry, titanium oxide nanoparticles are capable of providing better protection against UV rays than traditional sunscreens. Nanomaterials are also set to introduce a number of advantages in the electronics and computer industry. Their use will make it possible to increase the precision of electronic circuit construction at the atomic level, which will help in the development of numerous electronic products. Currently, many high-performance electronic devices are based on nanotechnology, such as Quantum Dot (QD) technology for LED displays and smartphones.

Nanomaterials have also improved the energy sector, thanks to energy savings. For example, solar panels use nanoparticles to improve their efficiency. In the case of wind turbines, the larger the blade the more electricity can be generated, so stronger and lighter nanomaterials are used. They can also fulfill essential environmental functions, for example, it has been discovered that graphene can filter common salts from water to make it drinkable, a solution that could lead to the desalination and purification of seawater for consumption.

Nanotechnology and nanomaterials are one of the fastest growing and potential markets in any sector. Do you want to apply this technology in your business? Contact our materials innovation team, our experts will study your case to offer you an effective and innovative solution.