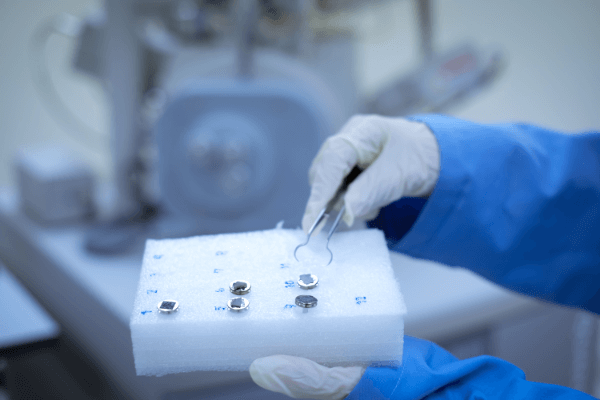

Nanomaterials: the materials of the future

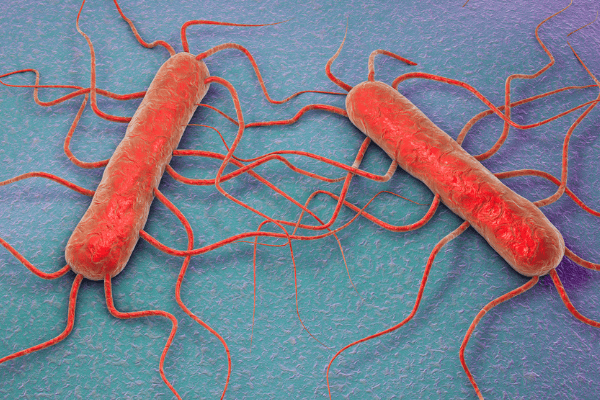

Nanotechnology and the development of nanomaterials have had a great impact on the fields of science and engineering, influencing future technologies and improving industrial solutions. In this article we explain what nanomaterials are, how they are obtained and their applications. What are nanomaterials? Nanomaterials are materials that are tiny in size and smaller in scale