Food microbiology testing is essential to ensure the quality of food products. Every food industry must be able to ensure the hygiene and safety of its products and avoid microbiological contamination of foodstuffs. In this article we explain what food microbiology is and the importance of testing in quality processes.

What is food microbiology?

Food microbiology is the study of the microorganisms that inhabit, produce or contaminate food. Its purpose is based on detecting and determining the germ content, minimizing the risks of contamination and preventing outbreaks of foodborne diseases. However, it covers not only the study of microorganisms that cause food spoilage, but also those that are necessary for food production, such as cheese, yogurt, bread, wine and other fermented foods.

In recent decades, special attention has been paid to understanding the different facets related to food production, quality and supply. In particular, the emergence of more powerful and precise molecular technology has provided us with the necessary tools to improve knowledge about the safety of the food products consumed. In this sense, the study of food microbiology has been fundamental in the improvement of the food industry in order to prevent food poisoning, detect critical points of microorganisms and other residues, as well as to develop new properties and improvements in food and its production.

Fundamentals of food microbiology in quality processes

Testing the microbiological activity of a food product on the one hand, evaluates the antimicrobial properties of food disinfection devices and, on the other hand, prevents foodborne diseases. If pathogenic organisms are detected in the early stages of food distribution, it is possible to prevent them from being ingested and infecting the gastrointestinal tract of their consumers. For this reason, the importance of microbiology in food has been increasing and has become a key element in quality, hygiene and safety, ensuring regulatory compliance. Similarly, forensic engineering analysis can be carried out on food to determine the origin that led to contamination, so that it can be prevented, hazards can be analyzed and critical control points can be identified.

Certain external factors can increase the risk of contamination of a food, such as temperature, humidity and exposure to oxygen and carbon dioxide. However, at the microbiological level, internal factors can also alter the composition of a food. For example, the pH level of a food itself can modify its bacterial content and enhance or diminish its growth. Therefore, it is essential to go deeper into food chemistry and perform quality control tests to ensure food safety. In this sense, food microbiology laboratories using molecular biology are able to carry out the necessary tests to detect bacteria such as salmonella, listeria or E. coli, among others, throughout the different stages of industrial production processes.

Food microbiology tests

The tests provide vital information about the manufacturing process, product properties and processing environment, such as the antimicrobial properties of a surface. They also provide information on whether or not the process follows regulatory guidelines.

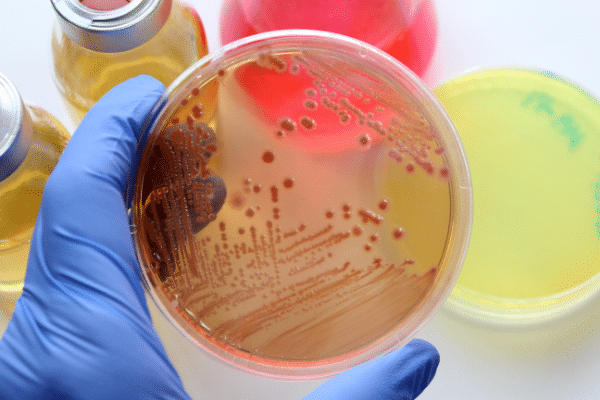

The most common test methods used in food microbiology laboratories are culture media, immunoassays and polymerase chain reaction. While culture media are used to identify and detect different types of microorganisms by culturing or growing them, immunoassay is used to measure the concentration of a macromolecule in a solution by using an antibody or immunoglobulin and polymerase chain reaction (PCR) test to identify DNA or RNA sequences of microorganisms.

In short, microbiology analysis in the food industry is an integral part of it and must be carried out to ensure food quality and hygiene, since its fundamental purpose is to identify and restrict harmful microorganisms that can spoil food and ensure safety against foodborne diseases. At Infinitia we have the best laboratories to carry out the fundamental food microbiology analysis in the industry. Contact our quality and testing team to offer you the best solution.