Thermography analyzes have become a very common method in the industry thanks to their effectiveness in preventing breakdowns and the wide variety of applications they offer. In this post we explain what this technology consists of, what its main advantages are and in which areas it is usually used.

What is thermography and how does it work?

Thermography is a technique used to measure the temperature of objects, places and living beings from a distance. For this, thermal or thermovision cameras are used. These equipments capture the wavelength of infrared radiation emitted by the molecules of the bodies and analyze the data obtained, together with other physical properties of the surface and the environment, to calculate the values accurately.

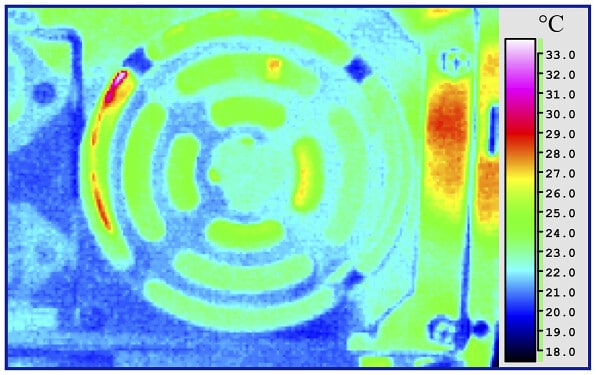

The result of infrared thermography is a two-dimensional radiometric image of objects, in which each pixel defines the temperature of an area. Thus, the global and local thermal characteristics are obtained, being able to diagnose possible pathologies in materials and buildings.

Advantages of infrared thermography

Thermography has a number of distinctive features that are very beneficial for organizations that decide to incorporate it into their procedures. These are some of its most outstanding features:

Non invasive

Thermographic analyzes are non-destructive tests that do not produce any type of damage on the studied components. This means that, unlike what happens with destructive tests, the materials retain their physical and functional characteristics intact, and can continue to be used as normal.

Specific

Thermal cameras provide an accurate display of the thermal values of each zone, since temperatures are represented graphically by color coding within heat maps. In this way, the spatial location of problems such as leak points in pipes, overheating of components or loss of insulation in electrical wiring is unequivocally identified.

Fast

It is a technique that can be performed quickly, comfortably, and systematically, showing thermal changes and thermoregulation of objects in real time. In addition, by not needing direct contact with the surfaces, it is not necessary to stop the processes for a long time, allowing companies to continue with their activity without major setbacks.

Multidisciplinary

Apart from prevention and maintenance tasks, infrared thermography collects thermal patterns and statistics on the evolution of temperatures. Given its capabilities, it is very useful in a wide variety of sectors, such as construction, architecture, aeronautical engineering, automotive, medicine, meteorology, food production or the preservation of monuments.

Industrial applications of thermography

As we have seen, the applications of infrared thermography in industry are very numerous. Next, we review some of the most common:

Building thermography

The purpose of building thermography is to make a diagnosis of the energy efficiency of the facilities by studying their insulation conditions and their thermal behavior. In this way, it helps to optimize the use of energy, limiting spending and reducing pollution in cities by rehabilitating buildings based on environmental sustainability criteria.

Predictive maintenance of machinery and electrical installations

The temperature measurement makes it possible to periodically monitor the status of the devices, being able to prematurely detect breakdowns in their parts, as well as faulty connections in the electrical installation. This is vital to extend the useful life of the equipment and prevent the appearance of failures in the machinery, saving costs in repairs and periods of inactivity.

Life tests of materials and products

Infrared thermography is also used to examine the behavior of materials under ordinary and extreme environmental conditions. These types of tests are used to estimate the useful life of the components that are going to be used in the manufacturing processes of machines, infrastructures and products, thus controlling the quality of the elements that pass through the production chain.

Failure analysis

The visualization of the temperature changes in the different zones helps to determine the exact place where the faults that prevent the normal operation of the equipment have occurred. The analysis of errors is an opportunity to optimize the design of materials and buildings for the future, facilitating greater efficiency.

Considering what has been seen, it seems clear that the potential of thermography to guarantee quality and optimize processes must be taken into account by any company. If you want to stay informed about the most used technological procedures in the industry, we invite you to follow our blog closely.