What is the abrasion tester?

The abrasion tester is a specialised piece of equipment that allows the wear resistance of materials to be evaluated by means of controlled abrasion tests. Its operation is based on simulating real-use conditions by applying friction or scraping to the surface of a sample using specific abrasive materials. This provides key data on the durability and mechanical strength of coatings, paints, plastics, textiles and other materials.

One of the unique features of the abrasimeter is its ability to test both dry and wet, and even with chemicals to assess a wear effect by combining, adapting and being able to perform customised tests to reproduce and simulate the requirements of different industrial and research sectors.

This team is essential in fields such as quality control and testing, characterisation of materials in innovation projects, and in approval for new materials and suppliersprocesses .

How does the abrasion tester work?

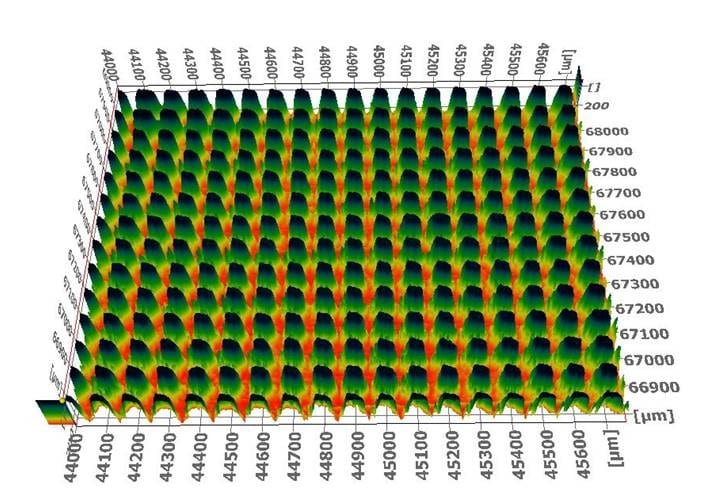

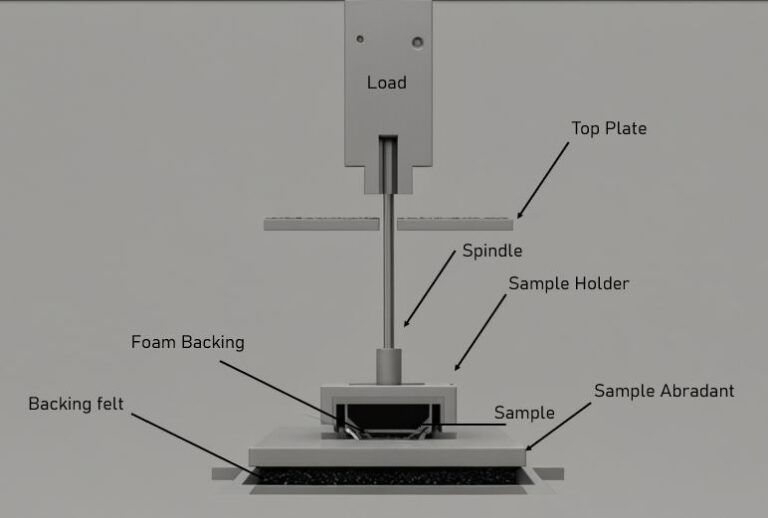

The abrasion tester works by means of a rotating or linear displacement system that applies a standard abrasive to the surface of the material to be tested. During the process, sensors record data such as mass loss, depth of abrasion or visual wear on the surface. These results are processed by specialised software that generates detailed reports with graphs and tables for easy interpretation. The equipment allows parameters such as speed, pressure and the type of abrasive used to be adjusted, ensuring the accuracy and reproducibility of the tests.

The interpretation of the results begins with the preparation of the sample, ensuring that it has optimal dimensions and conditions for the test. Once placed in the abrasion tester, the test parameters are set according to the regulations applicable to the material.

After completion of the abrasion cycle, alterations in the sample are assessed by visual observations, weight measurements or surface analysis by microscopy. The data obtained helps to determine the wear resistance of the material and its suitability for specific applications, enabling improvements in processes manufacturing and product development.

Benefits of the abrasion tester

A key benefit of the abrasion tester is its ability to simulate real-life conditions with very good reproducibility, providing accurate and relevant information to ensure product quality and durability.

In addition, its flexibility to adapt to various international standards, such as ISO 11998, makes it an indispensable tool for companies looking to market their products in global markets. The ability to perform abrasion tests on a wide variety of materials extends its usefulness, from textiles and paints to plastics and construction materials.

Abrasimeter equipment

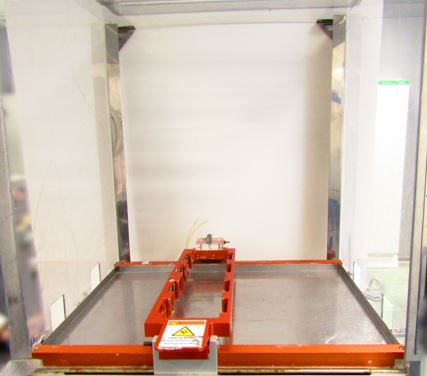

The Elcometer 1720 Abrasion & Washability Tester, used at INFINITIA, is a high precision abrasion tester designed to evaluate the wear resistance and washability of various materials. This equipment has an adjustable system that allows the configuration of key parameters such as applied pressure, abrasion speed and the type of abrasive used, adapting to the specific needs of each test.

Its robust and compact design ensures reliable performance even under heavy use, while its wet and dry testing capability makes it ideal for a wide range of applications.

In addition, the Elcometer 1720 is equipped with an automated data logging and control system, facilitating analysis of results and ensuring reproducibility of tests.

This equipment has established itself as an indispensable tool in research and quality control laboratories.

Equipment applications

The abrasion tester has a wide range of applications in industrial and research sectors, making it an essential tool for ensuring the quality and durability of materials. Some of its most relevant applications include:

- Abrasion resistance and adhesion testing: This equipment is essential for assessing the ability of materials to resist mechanical wear caused by friction or scraping. This type of test is commonly used on coatings, paints and construction materials, ensuring their suitability for specific applications.

- Washability testing: In the coatings industry, the abrasion tester is used to simulate repeated cleaning processes, assessing how coatings resist the action of cleaning agents and associated friction. This ensures that products maintain their appearance and functionality over time.

- Evaluation of cleaning processes: In sectors such as food and healthcare, the abrasion tester allows the effectiveness of different cleaning methods and products to be analysed without damaging the surface of the material. This is essential to ensure hygiene and safety standards.

- Textile analysis and garment : In the textile industry, the abrasion tester is used to measure the wear resistance of fabrics and garments, ensuring their durability. This is especially important for highly demanding products such as uniforms, sportswear and technical textiles.

- Quality control in plastics: Plastics manufacturers use the abrasion tester to assess the wear resistance of their products, such as packaging, electronic components and automotive parts. This material characterisation analysis is crucial to ensure that products are reliable and comply with applicable regulations.

- Automotive sector: In vehicle manufacturing, abrasion tester is used to ensure that materials used in interiors and exteriors withstand the wear and tear associated with daily use, improving the durability and aesthetics of vehicles.

- Furniture industry: Furniture manufacturers use the abrasion tester to assess the resistance of surfaces to scratches, friction and other types of wear, ensuring quality and customer satisfaction.

- Building materials: In this sector, it is essential that materials such as flooring and cladding have high wear resistance to ensure durability and safety. The abrasion tester accurately assesses these properties.

- Materials research and development: R&D laboratories use the Abrasimeter to develop new materials and coatings with improved wear resistance properties, contributing to innovation and sustainability in various fields.

In summary, the abrasion tester is an advanced and versatile tool that plays a crucial role in assessing the wear resistance of materials in numerous sectors. Its ability to simulate real-life conditions , together with its accuracy and adaptability, make it an essential piece of equipment for ensuring the quality and durability of products

At INFINITIA, this equipment is used to perform detailed analyses that enable companies to develop innovative and reliable solutions, meeting the most demanding market standards.

We show you some examples of the use of the abrasimeter in INFINITIA: