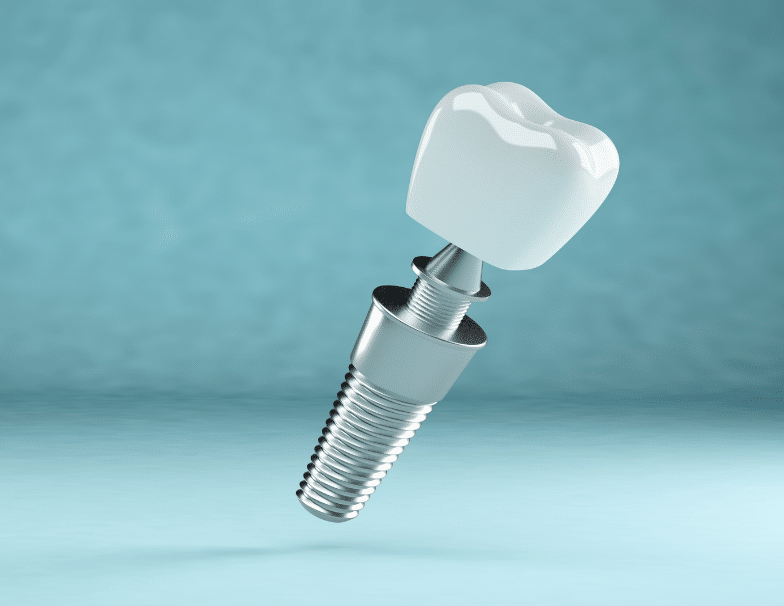

Biocompatibility is described as the ability of a material to generate an acceptable biological response during the time and contact mode of a specific application. Therefore, it should be known that a biomaterial is a material that will be in contact with some part of the body.

The design of the most appropriate test strategy is selected based on different factors involved in a company’s production processes such as product material, manufacturing methods and the purpose of the study.

What is a biocompatible material?

A biocompatible material is an element of synthetic or organic origin that can interact with biological systems. It is important to know the conditions of the recipient and to have information about the chemical and mechanical properties of the biomaterial to know if it will be a good support.

Examples of biocompatible materials are titanium, cobalt-chromium and its alloys or ceramic materials based on alumina, zirconia and magnesium oxide.

Types of biocompatibility tests

To determine the biocompatibility or toxicity of a material, different tests, trials and studies need to be carried out. Factors such as the general description of the material, its function or possible application, as well as its degree of contact with living tissue, the chemical nature and bioavailability of each chemical compound in the material must be considered. Thus, biocompatibility testing can be distinguished as follows:

- Analytical chemical tests

- In vitro tests

- Animal tests

Biocompatibility studies are a basic requirement to ensure compliance with legal regulations and are based on the basic biocompatibility standards published by the International Standards Organisation (ISO).

INFINITIA and the quality and material component checks

From INFINITIA’s technical team we develop different actions to check the quality and components of each material in the production process.

The actions that we carry out from our company cover a wide range of studies, tests and controls that cover the different phases of the production process and that respond to the different needs of the projects and business initiatives of our clients:

- Material failure analysis: this is used to determine the mode and cause of failure in areas such as production, product or market claims.

- Quality control and testing: physico-chemical, nutritional and microbiological analyses are incorporated to develop tests in accordance with international standards and thus define in-house tests to replicate operating conditions.

- Reverse engineering: analysis of market products with the aim of understanding their composition, operation, possible interactions between components and the best designs or selection of materials.

- Technical consultancy: advice and resolution of doubts with a prior assessment and a series of proposals for improvement.

Biocompatibility in forensic engineering?

Innovation is Infinitia’s main hallmark in the different services it provides to its clients. In the field of biocompatibility, it is necessary to talk about the relationship between quality controls and forensic engineering, a discipline that deals with investigating the causes and consequences of a failure in a certain product.

The purpose of forensic engineering is to investigate the origin of the error in order to prevent it from occurring in the future.

The most common failures include those that influence the loss of functionality, the quality of the final product or the condition of the raw materials.

INFINITIA applies forensic engineering to the investigation of biocompatible materials.

At INFINITIA we apply forensic engineering to the investigation of materials, structures, components or systems. In short, our work consists of finding out, asking questions, performing a materials test, carrying out an analysis in the laboratory or reproducing a simulation of the failure. With this, we define the incident and offer a solution, which can also be related to biocompatibility.

Thanks to the work, experience and professionalism of our Forensic Engineering team, Infinitia provides you with an efficient and tailor-made service in the resolution of material-related problems.

Would you like to count on the help of our laboratory to evaluate the biocompatibility of your materials? Contact with our team.