What is the charpy impact test?

The Charpy pendulum impact tester is an essential piece of equipment in the field of mechanical testing , designed to assess the resistance of materials to impact loads and in material approval processes.

It is used to measure the toughness and energy absorption capacity of different materials before fracture, providing crucial information about their behaviour under real-use conditions.

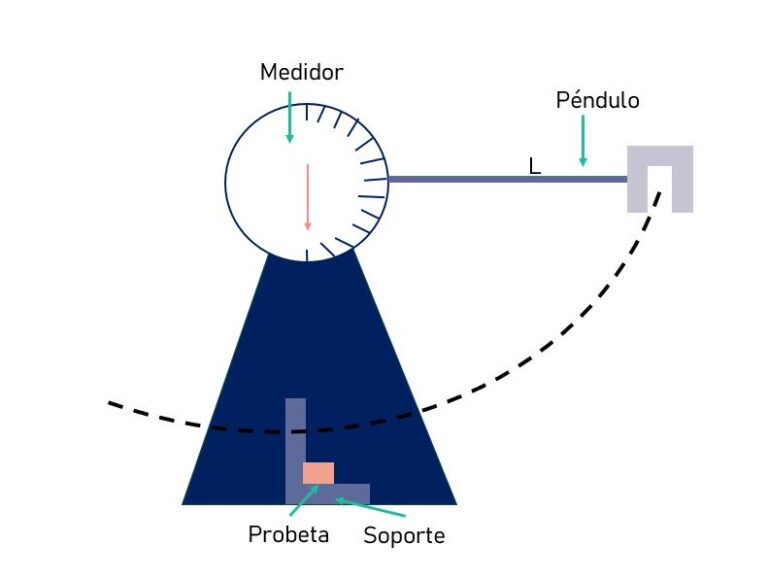

The Charpy impact test is based on a pendulum that strikes the sample with a predefined energy, allowing to determine the amount of energy absorbed by the material during the fracture .

This equipment is widely used in quality control and research laboratories, as well as in the field of failure analysis and forensic engineering. This test is essential in sectors such as metallurgy, automotive and construction, where impact resistance is a determining factor in the safety and quality of materials.

How does the charpy impact test work?

The operation of the Charpy impact machine begins with the preparation of the sample, which is machined with a standardised notch to ensure comparable results. Once placed on the machine stand, the pendulum is released from a set height and strikes the sample at its centre point.

The amount of energy absorbed by the material is measured as a function of the height reached by the pendulum after impact. This procedure allows the fracture toughness and ductility of different materials to be evaluated, helping in the selection of materials for specific applications.

The interpretation of Charpy impact test results is simple and is based on the amount of energy absorbed by the sample before fracture. If the material absorbs a large amount of energy, it is considered tough and impact resistant, while a low energy absorption indicates a brittle and failure prone material.

Key steps include sample preparation, correct alignment on the machine, execution of the test and analysis of the values obtained, which can be compared with international standards to validate performance.

Benefits of the charpy impact test

A key benefit of the Charpy impact test is its ability to simulate realistic impact conditions, allowing the suitability of materials to be assessed in demanding environments.

This test is widely used in industry to improve the safety of structures and components by ensuring that the selected materials perform adequately under dynamic loads.

Moreover, its speed and reproducibility make it an efficient tool for quality control in the manufacture of materials.

Equipment of the charpy impact test

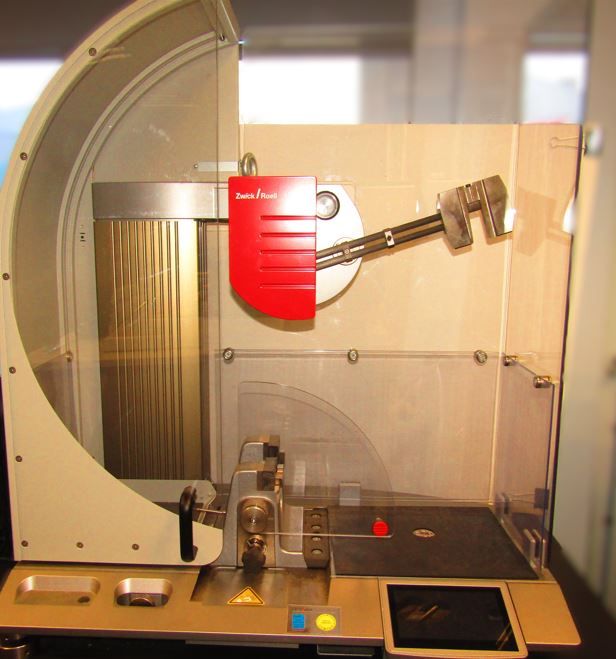

The Zwick/Roell HIT5.5P, used at INFINITIA, is a high precision pendulum impact tester designed for Charpy and Izod testing of plastics and metallic materials.

This equipment has an impact capacity of up to 5.5 joules, which makes it ideal for evaluating the toughness and strength of materials under controlled dynamic loads, and can follow norms and standards such as

Its digital measurement system provides accurate records of the energy absorbed during fracturing, ensuring precise interpretation of the results.

In addition, the HIT5.5P incorporates an automatic sample alignment mechanism and an optimised damping system to reduce vibrations, improving test reproducibility.

Equipment applications

The Charpy pendulum is used in a wide variety of industrial and research sectors to assess the impact resistance of materials. Some of its most relevant applications include:

- Comparison of material performance under impact loading: Used to evaluate how different materials react to dynamic loading, facilitating the choice of the most suitable material for specific engineering and manufacturing applications.

- Material selection in engineering applications: The Charpy impact test helps engineers determine which materials have the best combination of strength and ductility for use in critical structures such as bridges, vehicles and aircraft components.

- Quality control in manufacturing processes: In industrial production, this equipment makes it possible to verify that the materials used meet the requirements of mechanical strength and durability, ensuring the quality of the finished products.

- Verification of compliance with material standards: The Charpy impact test is required by multiple international standards, such as ASTM and ISO, to validate the quality and safety of materials in various industrial applications.

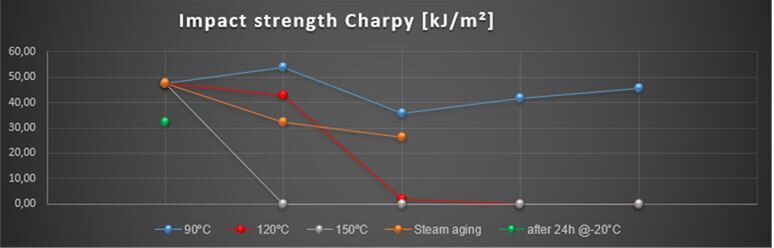

- Assessment of the suitability of materials for extreme environments: Used in industries such as aerospace and petrochemicals to test materials that must withstand severe temperature and pressure conditions without compromising their structural integrity.

In conclusion, the Charpy impact machine is an essential tool for the mechanical characterisation of materials, providing key information on their strength and behaviour under dynamic loading.

Its accuracy, speed and versatility make it an indispensable piece of equipment in materials research and quality control in industry.

At INFINITIA, this equipment is used to ensure that the materials analysed meet the highest safety and performance standards, contributing to the development of innovative solutions in multiple sectors.

Here are some examples of the use of the charpy impact test at INFINITIA:

Recyclability and re-use of aluminium swarf to obtain new high quality raw material