What is the Climatic Chamber?

The climatic chamber is an essential piece of equipment in the field of product research and development, used to simulate controlled environmental conditions and reproduce various temperature and humidity scenarios. This tool is key to recreate different temperatures and humidity levels in order to evaluate the behavior and resistance of materials and products to adverse climatic factors. From the automotive to the pharmaceutical industry, its application ensures that products can withstand.

How does the climatic chamber work?

The operation of the climatic chamber is based on a precise control system that regulates the temperature and relative humidity within its internal space, allowing test objects to be subjected to a wide variety of conditions. These tests are essential for predicting how products will perform in different geographic environments or extreme situations,

such as high temperatures, intense cold, or high humidity.

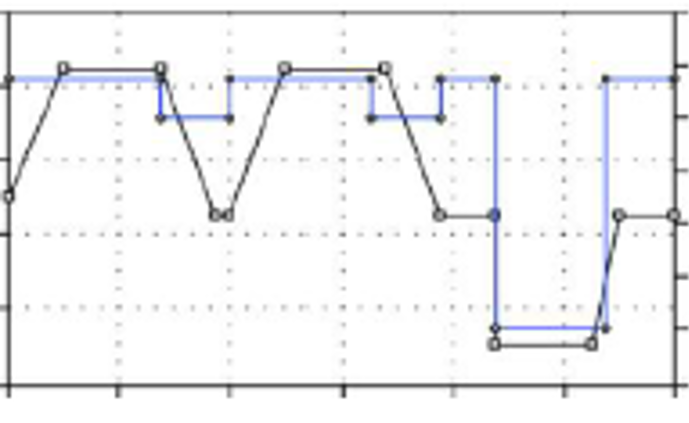

The testing process within a climatic chamber is systematic and highly controlled. First, a cycling program is defined that establishes the environmental conditions to be replicated, as well as the exposure times at each stage. Next, the product or material is placed inside the chamber, ensuring that the sensors are well positioned to monitor changes in temperature and humidity.

After running the test program, the collected data is analyzed to identify how the object has reacted to the simulated conditions. This analysis makes it possible to determine whether the product meets durability standards or is susceptible to failure under certain environmental conditions. Climatic chambers, therefore, are essential tools in quality control and in the development of products that must be reliable and durable.

Benefits of the climatic chamber

A key benefit of the climate chamber is its ability to perform accelerated aging tests. Rather than waiting months or years to see how a product deteriorates under natural conditions, the chamber can simulate these effects in a matter of days or weeks. This is essential in industries such as automotive, electronics and aeronautics, where resistance to environmental conditions can be a decisive factor in a product’s success in the market place.

In the pharmaceutical industry, for example, climatic chambers are used to perform stability tests on drugs, simulating extreme conditions that the products might face during storage and transport. These tests ensure that drugs will remain safe and eficient under various climatic conditions.

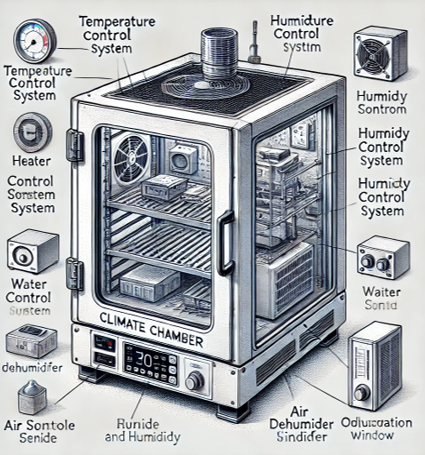

Climatic Chamber Equipment

The WEISS Technik ClimeECO model, used by INFINITIA, is an advanced climatic chamber designed for precise and controlled testing under extreme environmental conditions. This specific version of the climatic chamber stands out for its ability to adjust both temperature and humidity accurately, allowing a wide range of climatic scenarios to be simulated with high fidelity. Thanks to its state-of-the-art technology, it is possible to perform ramps of variation in temperature and humidity, simulating both gradual and abrupt changes in the environment. This makes it an essential tool for industries that need to evaluate the durability and resistance of their products under different environmental stress conditions.

On a general level, climatic chambers such as the ClimeECO are used in a variety of industrial sectors, including automotive, electronics, and pharmaceuticals, where products must meet stringent quality standards. The ability of this equipment to replicate exact climatic conditions makes it indispensable for ensuring that products not only comply with regulations, but also offer long-term fiability and durability.

In particular, the WEISS Technik ClimeECO has established itself as one of the most robust and accurate options in its class. This equipment not only allows standardized temperature and humidity tests to be. The system also offers the option of testing with demineralized water, ensuring that internal components are not damaged during the testing process. This feature is especially useful in sectors such as forensic engineering, where it is crucial to replicate the exact conditions under which material or product failures occur. With the ClimeECO, it is possible to accurately identifice these failures, facilitating improved design and product quality.

Equipment applications

The climatic chamber has multiple applications in various industrial and research fields, where it is required to simulate environmental environments to test products or materials. Some of the most relevant applications are detailed below:

- Accelerated environmental testing: This is one of the most common applications. The climatic chamber is used to subject products to accelerated aging tests. These tests make it possible to simulate the effects of the passage of time on a product by subjecting it to extreme conditions in repeated cycles. This is key in the electronics and automotive industries, where products must be able to withstand the wear and tear caused by sudden and prolonged climatic changes.

- Standard temperature and climate tests: Climatic chambers are also used to carry out tests according to regulations and standards that establish specific temperature and humidity ranges. These tests are necessary to certificate that a product complies with international regulations and is suitable for distribution in global markets. These tests are crucial for the aviation industry, which evaluates how aircraft react to transitions between different altitudes and climates.

- Cycle programming with ramp design: Another important use of the

climatic chamber is the possibility of programming customized climatic cycles, including controlled variations of temperature and humidity over time. This makes it possible to simulate environments with abrupt or gradual climatic changes, evaluating how they affect the behavior of materials or products. - Temperature and relative humidity testing: The climatic chamber is capable of monitoring both temperature and relative humidity (RH) with high accuracy, which is essential for analyzing how the combination of these factors affects the integrity of a product. These tests are especially important in the pharmaceutical industry, where it is crucial to ensure the stability of drugs and products under specific climatic conditions.

WEISS Technik’s ClimeECO climatic chamber model at INFINITIA incorporates all these functionalities, offering precise control over the environmental conditions inside the chamber. This equipment is ideal for companies that need to simulate extreme environments to validate the quality of their products prior to commercialization, as it guarantees fiable and consistent results that allow decisions to be made based on accurate data.

Conclusion

Climatic chambers are essential tools in the development and quality control of products that must withstand extreme environmental conditions. Their ability to simulate different environments and perform accelerated aging tests makes them a vital resource for the automotive, aerospace, electronics and pharmaceutical industries.

The Climatic Chamber model and its advanced version ClimeECO the WEISS Technik, used at INFINITIA, offer precision and reliability in environmental testing, ensuring that products meet the highest standards of durability and quality.

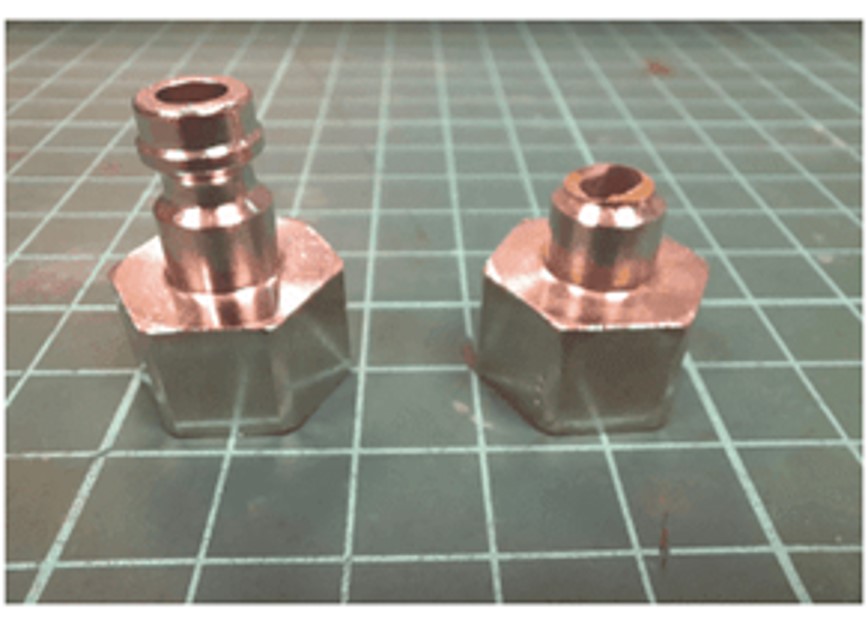

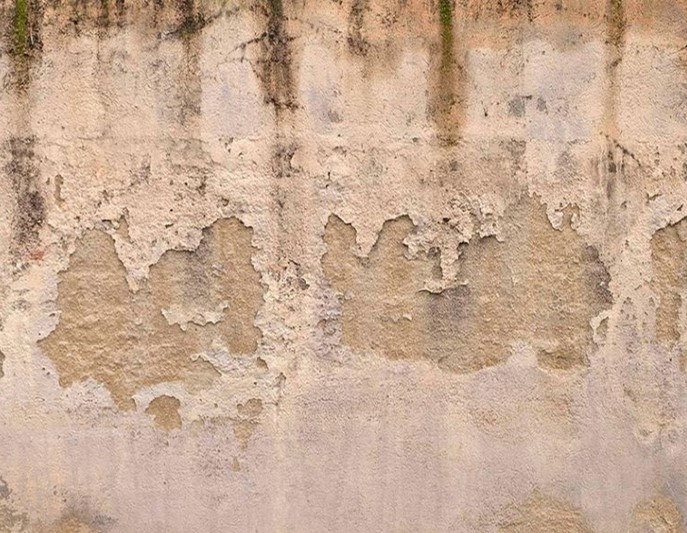

Here are some examples of the use of the INFINITIA Climatic Camera:

Customized moisture testing of insulating materials for supplier approval