What is differential scanning calorimetry (DSC)?

Differential Scanning Calorimetry (DSC) is an essential analytical technique in the study of the thermal properties of materials. It is widely used in the research and development of new materials, as well as in quality control, forensic engineering cases, and in various industrial sectors.

DSC measures the amount of energy a sample absorbs or releases during a heating or cooling process, providing crucial information about thermal transitions such as melting, crystallization and glass transition. This technique is especially valuable for the analysis of polymers, as it allows determining the degree of crystallinity, thermal stability and thermal history of materials. In addition, DSC is essential in the characterization of metallic materials, foods, adhesives, thermal insulators, and organic and thermoelectric materials. The accuracy and reproducibility of the results obtained with DSC make this technique an indispensable tool in the advancement of materials science.

How does the DSC work?

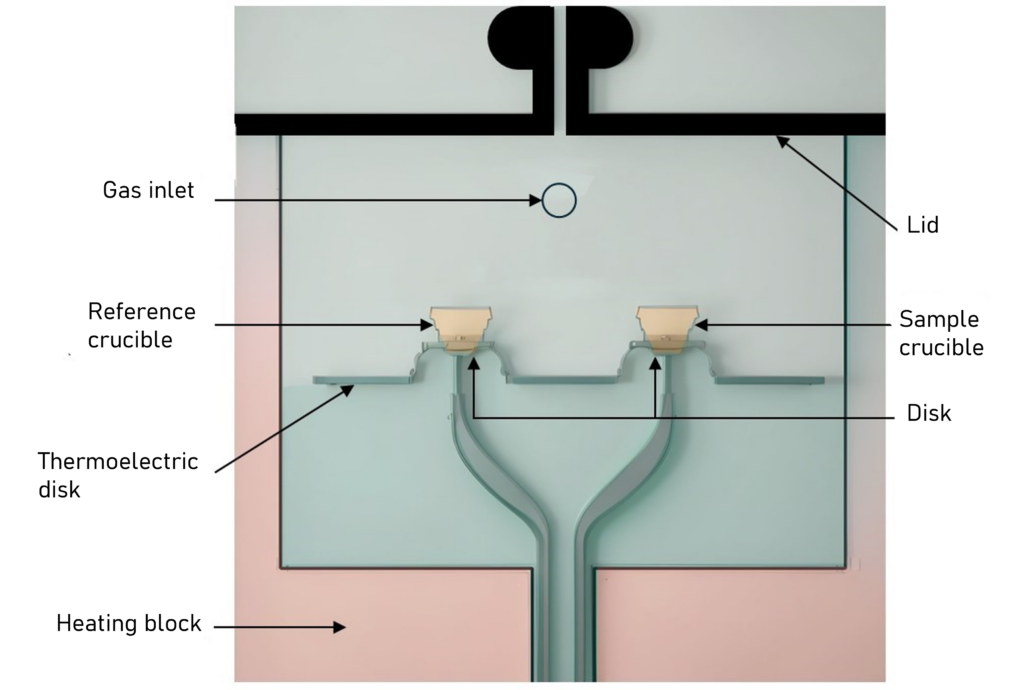

The operation of DSC is based on the measurement of the difference in heat flow between a sample and an inert reference when both are subjected to the same controlled temperature regime. The process begins with the preparation of the sample, which is placed in a small vessel or crucible. This crucible, together with an empty reference crucible, is inserted into the DSC. A temperature program is then established which may include heating and cooling cycles at controlled rates. As the temperature of the system changes, the equipment records the difference in heat flux between the sample and the reference.

The principle behind this technique is that thermal transitions in the sample (such as melting or crystallization) will require or release energy, which is detected as differences in heat flow. These differences are plotted on a thermogram, where peaks and valleys indicate specific thermal events. Interpretation of these graphs allows scientists to deduce the thermal properties and composition of materials. Detailed analysis of these results provides valuable information about the purity of the materials, their thermal stability and their behavior under different temperature conditions.

Benefits of DSC

The use of DSC offers multiple benefits in both scientific research and industrial applications. One of the key benefits of DSC is its ability to provide detailed and accurate information on the thermal properties of materials in a short period of time. This is especially useful in the research and development of new materials, as it allows scientists to quickly evaluate the thermal characteristics and stability of materials under various conditions.

Another significant benefit of DSC is its ability to perform nondestructive analysis. This means that analyzed samples can be examined without altering their structure, allowing for repeated and comparative studies. In addition, DSC is extremely versatile and can be adapted to a wide range of materials, from polymers and metals to foods and chemicals. This versatility makes it an essential tool in a variety of industrial sectors, including plastics manufacturing, the food industry, adhesives production and advanced materials research.

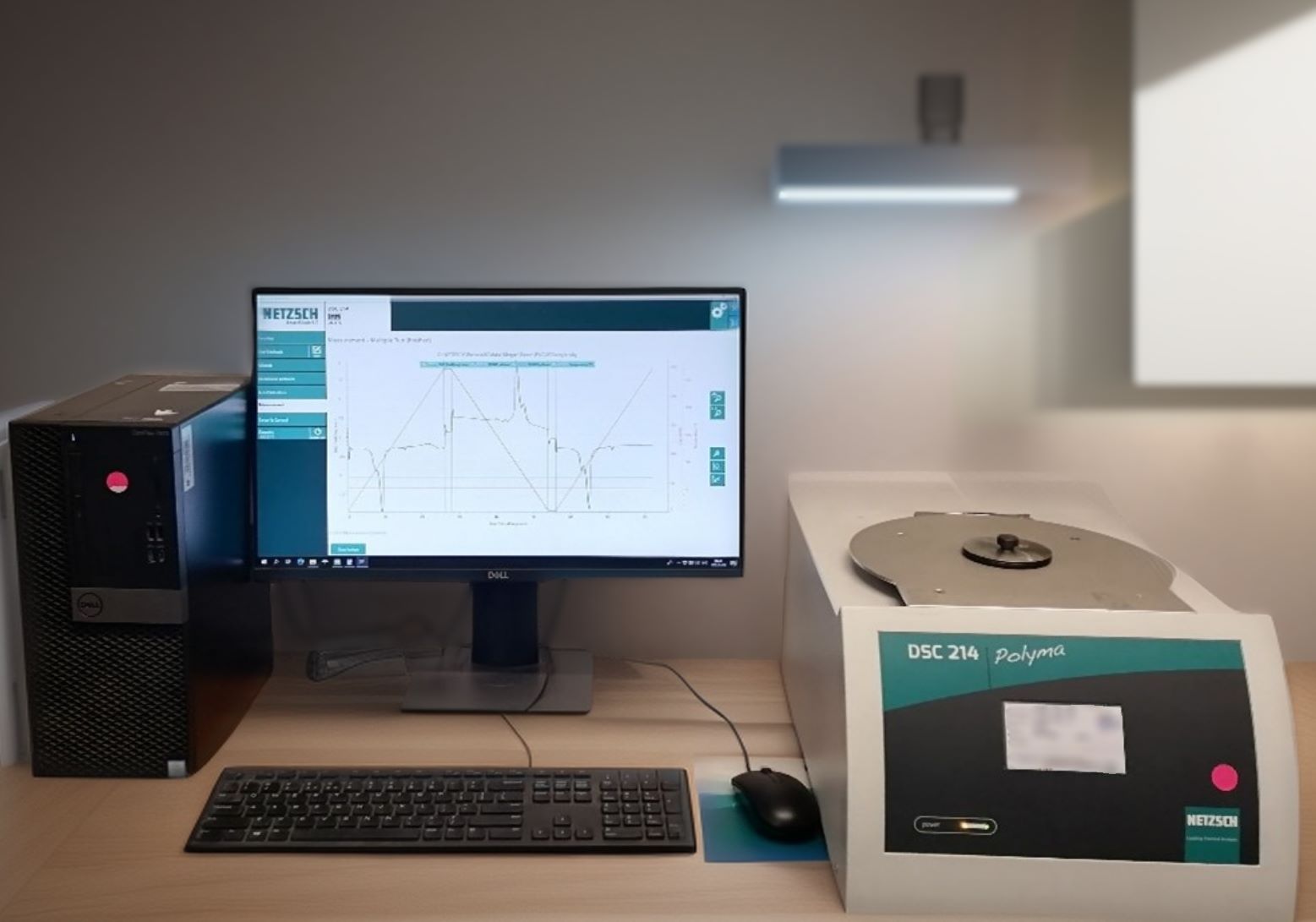

Equipamiento DSC

At INFINITIA we have the DSC 214 Polyma, which represents a significant advance in differential calorimetry technology. This model offers high sensitivity and accuracy in heat flow measurement, along with an intuitive user interface and advanced software capabilities that facilitate data analysis. The DSC 214 Polyma is especially valued in polymer and other materials research due to its versatility and robustness.

DSC applications

DSC has extensive applications in various research fields and industrial sectors. In the field of polymers, it is used to study the aging and degradation of materials, identify grades and blends, evaluate the thermal (processing) history, determine the glass transition (Tg), melting point and recrystallization temperature, as well as the degree of crystallinity. In addition, it is crucial to evaluate the stability of materials against oxidation and aging.

Polymers:

- Material Aging/Degradation: DSC allows identification of how polymers age and degrade over time, providing critical information to improve product durability.

- Grade and Blend Identification: Facilitates accurate identification of different grades and blends of polymers, which is essential to ensure quality and consistency in production.

- Thermal History Evaluation (Processing): Allows evaluation of the thermal history of polymers, identifying previous heating or cooling processes that may affect the final properties of the material.

- Glass Transition (Tg), Melting Point and Recrystallization Temperature: Provides accurate data on glass transition, melting point and recrystallization temperature, fundamental aspects to understand the thermal behavior of polymers.

- Degree of Crystallinity: Helps determine the degree of crystallinity of polymers, a property that influences the stiffness and strength of the material.

- Stability against Oxidation and Aging: Evaluates the stability of polymers against oxidation and aging, ensuring product longevity and performance.

Other Sectors:

Metals and Alloys: DSC is used to study the thermal properties of metals and alloys, including melting, solidification and phase transitions.

Food: In the food industry, DSC is used to analyze the thermal properties of food, helping to improve production processes and final product quality.

Adhesives: The analysis of adhesives by DSC allows optimizing their formulation and performance under different temperature conditions.

Thermal Insulation: DSC is used to evaluate the efficiency of thermal insulation materials, contributing to the development of more energy-efficient products.

Organic and Thermoelectric Materials: This equipment also finds applications in the analysis of organic and thermoelectric materials, providing essential information for the research and development of new materials with specific properties.

These applications highlight the relevance of Differential Scanning Calorimetry (DSC) in the development of science and technology, offering practical and effective solutions to various challenges in research and industry. DSC has become an essential tool for those who need accurate and detailed data on the thermal properties of materials, allowing process optimization and product quality improvement.

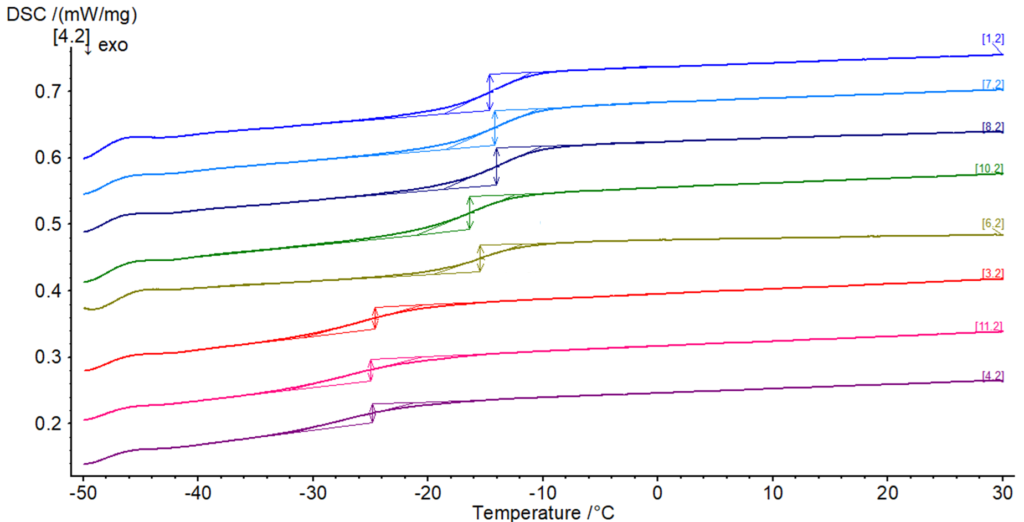

Here are some examples of the use of DSC at INFINITIA:

If you need to apply this equipment in one of your projects, do not hesitate to contact us. At Infinitia we are here to help you.