What is the goniometer or tensiometer?

The goniometer or tensiometer is a tool used to measure the contact angle or surface tension. It is used to study the interaction properties between liquids and solids, especially on surfaces.

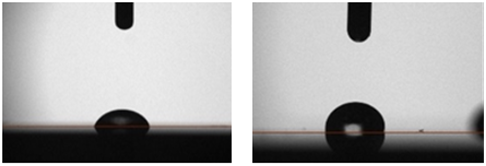

This equipment measures the angle of a liquid droplet in contact with a solid surface, providing key information on properties such as hydrophobicity, wettability and surface energy.

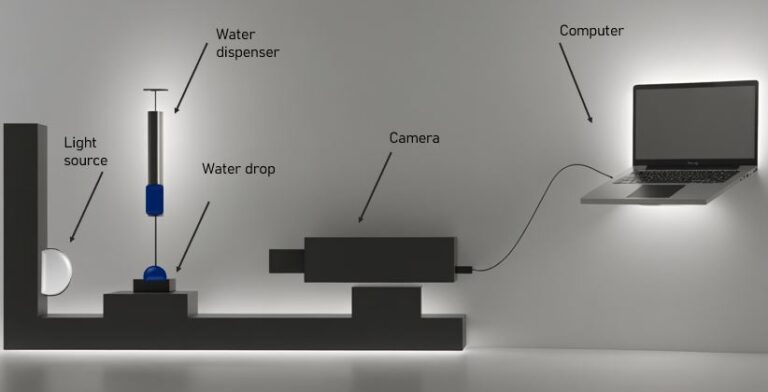

The operation of the equipment is based on the capture and analysis of images of the droplet on the surface, using advanced algorithms that calculate the angle with high precision.

This analysis is essential in fields such as quality control and testing, where liquid-solid interaction affects the functionality or quality of products, such as coatings, adhesives and textiles.

How does the goniometer or tensiometer work?

To obtain results, the equipment uses an illumination system and high-resolution cameras that capture the shape of the droplet from different angles. The collected data is processed by specialised software that calculates key parameters such as static and dynamic contact angle, surface free energy and interfacial tension. This approach ensures detailed and repeatable analysis of surface properties, allowing accurate assessments to be made even on samples with complex geometries.

Interpretation of the results involves looking at the contact angle values and their relationship to the surface properties of the material. A small angle indicates good wetting, while a large angle reflects hydrophobic properties. The steps to perform a measurement include sample preparation, placement of a controlled droplet on the surface, image capture and automated analysis using software. These results are essential for processes such as coating characterisation, material selection or adhesive improvement.

Benefits of the contact angle

A key benefit of contact angle equipment is its ability to perform non-destructive analysis, allowing samples to be evaluated without altering their physical properties or chemical . This makes it a versatile tool for research and quality control laboratories that need to characterise surfaces with high accuracy.

In addition, its ability to analyse dynamic and static angles, as well as advanced parameters such as interfacial rheology, positions it as an essential piece of equipment in sectors such as energy, biomedicine and advanced coatings.

Goniometer or tensiometer equipment

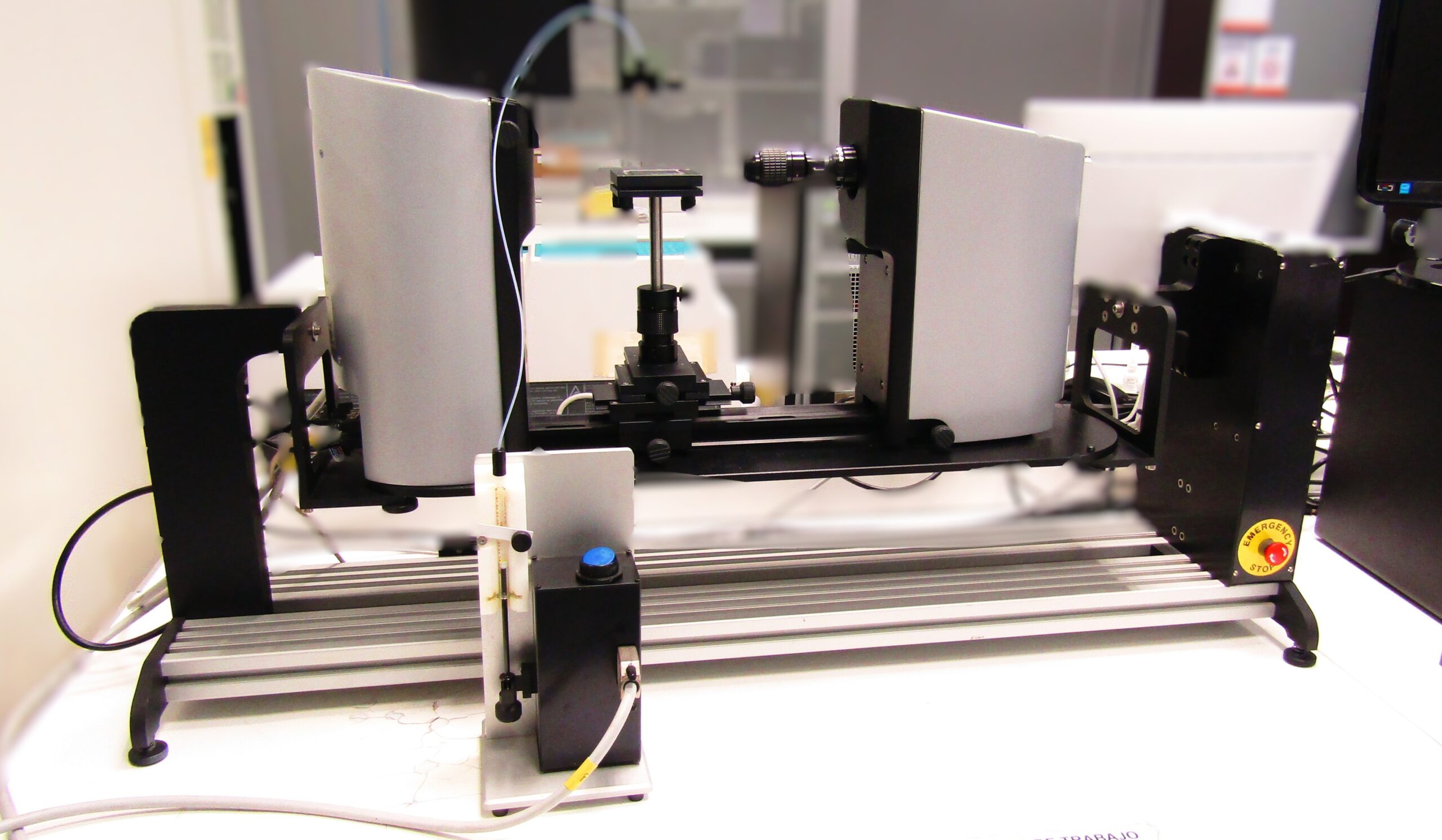

The Theta Flex model used at INFINITIA is a state-of-the-art equipment designed to perform accurate measurements of contact angle, surface tension and surface free energy. This model stands out for its ability to perform advanced analyses, such as dynamic and static contact angles, as well as interfacial rheology. It incorporates a high-resolution optical system and integrated software to capture detailed images of the interaction between liquid and solid, ensuring reliable results.

In addition, Theta Flex features modular accessories that allow customisation of tests to meet specific research needs, from material homologation to biomedical surface analysis. Its ergonomic and compact design makes it easy to use in laboratories, while its intuitive interface optimises real-time analysis, significantly improving workflow efficiency.

Equipment applications

Contact angle equipment has a wide variety of applications in industrial and research sectors. The most relevant ones are highlighted below:

- Static and dynamic contact angles: This equipment measures both static and dynamic contact angles, which is essential for assessing the stability and wetting properties of surfaces under different conditions. This is applied in sectors such as the coatings and adhesives industry, where wetting properties directly affect product performance.

- Surface energy assessment: The ability to measure surface free energy is crucial for characterising materials with specific properties, such as water-repellent coatings or surfaces designed to improve adhesion. This analysis is widely used in advanced materials research and in the development of technologies such as self-cleaning paints.

- Surface and interfacial tension: This equipment allows the measurement of tension at liquid-solid and liquid-liquid interfaces, providing key information for the formulation of emulsions, coatings and pharmaceuticals. This type of analysis is essential in industries such as cosmetics and food.

- Interfacial rheology: In advanced applications, the contact angle equipment also evaluates viscoelastic properties at interfaces, which is relevant in the development of thin films, functional coatings and membranes. This analysis is particularly useful in biomedical and renewable energy research.

- Optimisation of adhesives and coatings: In sectors such as automotive and construction, the equipment is used to analyse and improve the adhesion and coating properties of materials, ensuring their durability and efficiency under real-use conditions.

- Glass, enamel and ceramics testing: This equipment is also applied in the evaluation of the properties of materials such as glass, enamel and ceramics, helping to optimise their design and functionality for various industrial and architectural applications.

- Textile industry: In the textile industry, the contact angle is used to evaluate the water and grease repellency (hydrophobicity and oleophobicity) of fabrics, allowing the development of products with specific performance characteristics, such as waterproofing or stain resistance,

- Characterisation of biomedical materials: In biomedical research, the equipment is used to analyse the interaction between surfaces and biological fluids, helping to optimise medical devices and implantable materials.

- Forensic engineering: This equipment can also be used in the field of forensic engineering to analyse surfaces and materials in cases of failure or technical investigations, providing key data to identify causes and improve future designs.

- Development of smart surfaces: This equipment is a key tool in the creation of functional surfaces, such as self-cleaningcoatings, anti-fouling or non-stick , which are increasingly in demand in technology and consumer industries.

In conclusion, the goniometer or tensiometer is an advanced tool that plays a crucial role in the characterisation of surfaces and the evaluation of liquid-solid interactions. Its accuracy, versatility and ability to adapt to various applications make it an essential resource for laboratories working in innovation and quality control and testing.

At INFINITIA, this equipment is used to provide accurate data that contributes to the development of innovative solutions that meet the most demanding standards, to the development of productssafe and quality.

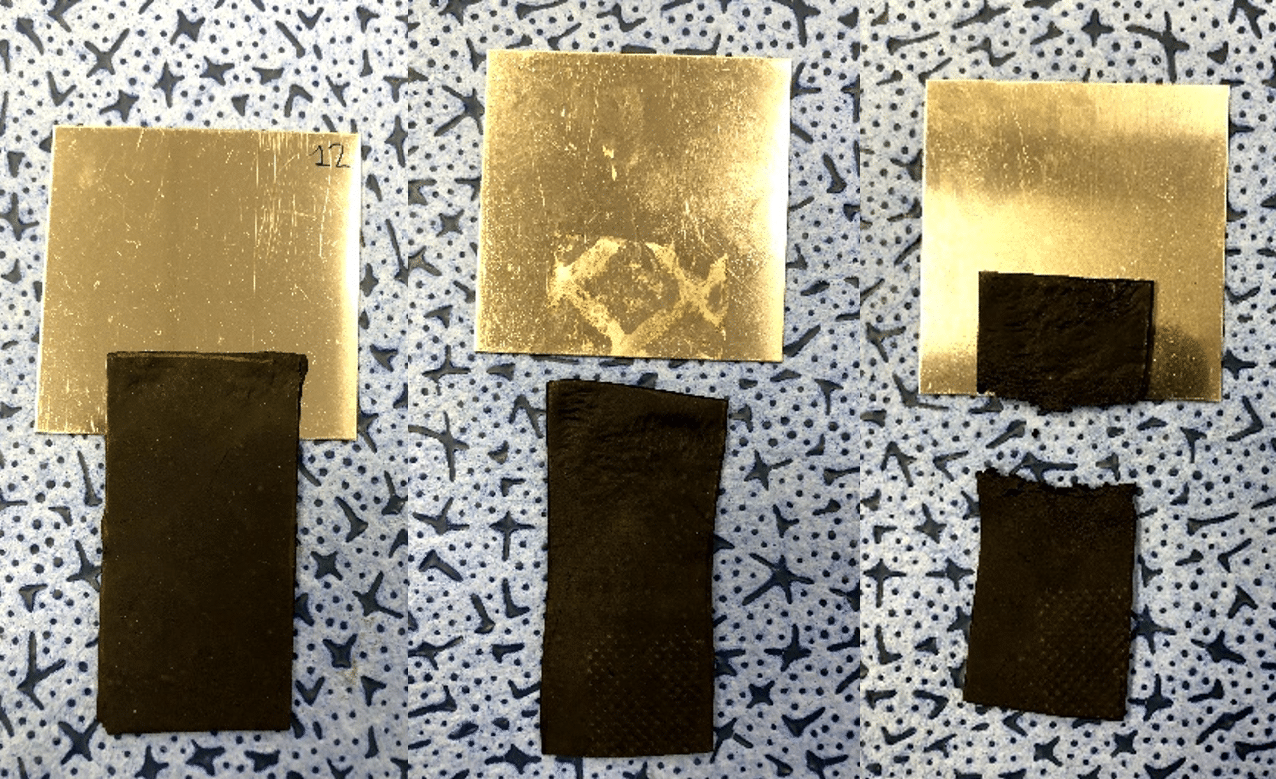

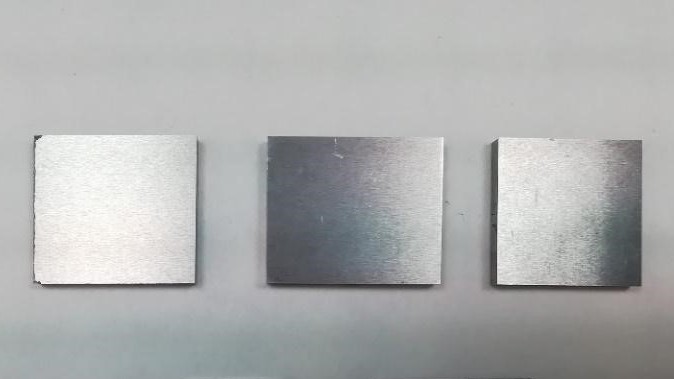

Here are some examples of how to use the INFINITIA contact angle:End of form

New materials through modifications of the surface finish on glass