What is a High Accuracy 3D Laser Scanner?

The High Accuracy 3D laser scanner is an advanced measuring device that allows three-dimensional objects to be digitised with exceptional resolution and accuracy.

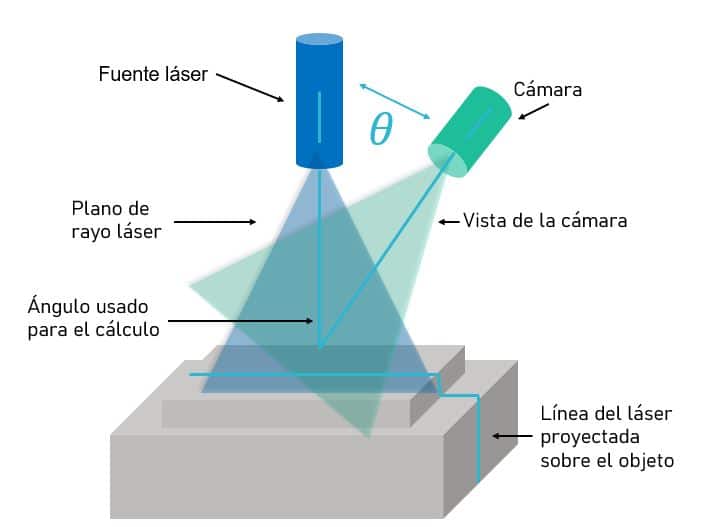

Its operation is based on the emission of a laser beam that scans the surface of the object and captures millions of points in a short period of time, generating a 3D point cloud that faithfully represents the geometry of the object.

This type of technology has become an essential tool in many industries, from reverse engineering to quality control, as it facilitates the production of detailed digital models of parts and structures.

At INFINITIA, we are committed to innovative technological solutions, and the implementation of 3D scanning allows us to optimise our processes in various areas, from the digitisation of mechanical components to the evaluation of surfaces with minimum tolerances.

How does a High Accuracy 3D Laser Scanner work?

The scanning process with a high-precision 3D laser scanner follows a series of fundamental steps:

- Preparation of the object and calibration of the scanner: The part is positioned in a suitable environment to minimise light interference and optimise data capture.

- Laser beam emission: The scanner projects a laser pattern onto the surface of the object and integrated cameras record the deformations of the reflected light.

- 3D point cloud generation: From the captured information, an accurate digital representation of the object’s geometry is created.

- Data processing and optimisation: Using specialised software, the data obtained is refined, eliminating noise and ensuring a detailed surface reconstruction.

- Export and analysis of the digital model: The results are integrated into 3D CAD design systems for inspection or manufacturing.

At INFINITIA, this workflow allows us to guarantee the quality of our analyses and offer precise solutions in areas such as industrial quality control and advanced manufacturing.

Benefits of the High Accuracy 3D Laser Scanner

One of the main benefits of using a high-precision 3D laser scanner is the ability to capture minute details with sub-millimetre accuracy, making it ideal for applications such as wear and deformation analysis, where meticulous inspection of parts is required.

In addition, this equipment significantly optimises rapid prototyping time and costs by efficiently digitising components and generating three-dimensional models ready for modification or printing in additive manufacturing.

At INFINITIA, we use this technology to streamline our product development processes, such as in design and innovation, ensuring that each analysis meets the highest standards of accuracy and reliability.

High Precision 3D Laser Scanner Equipment

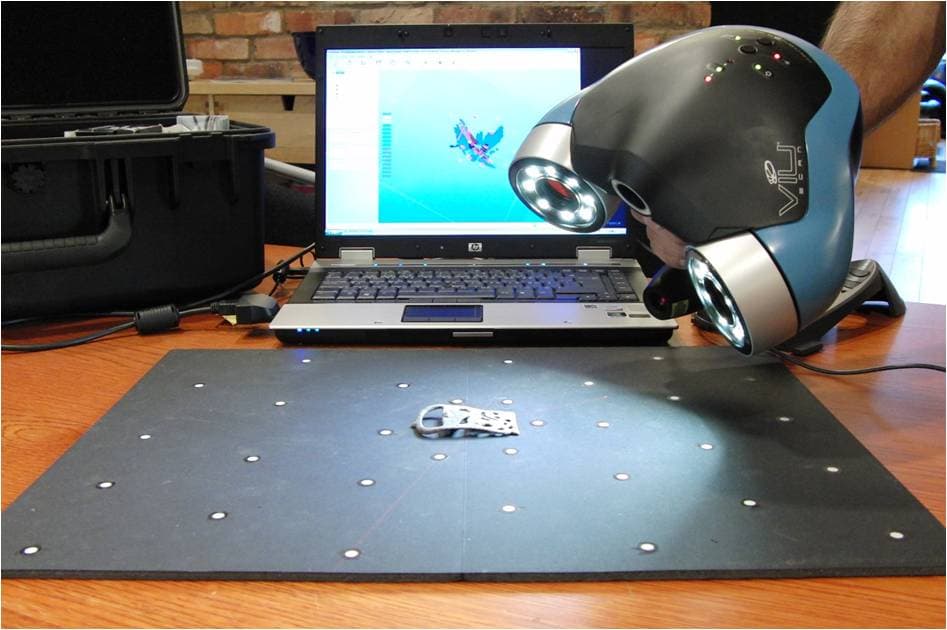

At INFINITIA we have the equipment , a high-precision 3D laser scanner that allows us to carry out detailed studies in applications such as the inspection of mechanical parts and computer-aided design (CAD).

This model stands out for its high resolution scanning capacity and its compatibility with multiple export formats, facilitating integration with different modelling software.

Compared to other systems on the market, the Creality Raptor X offers an optimal combination of accuracy, speed and ease of use, making it an indispensable tool in our innovation and quality control strategy.

High Accuracy 3D Laser Scanner Applications

3D laser scanning has become an indispensable tool in many industrial and research sectors, as it allows the fast and accurate capture of the geometry of any object.

Thanks to its ability to generate detailed digital models, the Creality Raptor X is used in a variety of applications that optimise production processes, reduce errors and improve product quality.

Their main applications are described below:

- Industrial quality control: 3D scanning is a key technology in quality inspection, as it enables non-contact, high-precision measurements. In industries such as automotive and manufacturing, this equipment is used to compare manufactured parts with their original CAD designs, detecting dimensional deviations and possible defects before assembly. At INFINITIA, we use 3D scanning to ensure accuracy in manufacturing processes, allowing us to detect minute variations that could affect the performance of a product. This metrological control capability is essential to ensure that components meet technical specifications and quality standards.

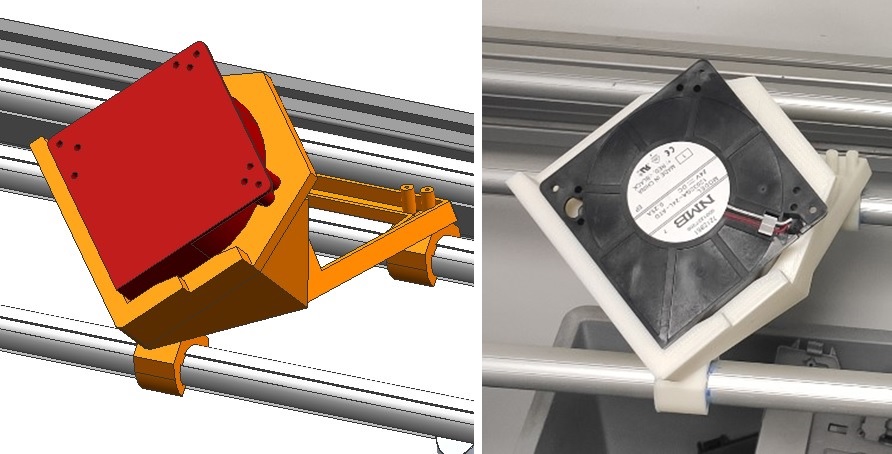

- Computer Aided Design (CAD): 3D scanning facilitates the integration of physical objects into digital environments through its compatibility with CAD software. This process allows engineers and designers to make modifications to scanned parts, optimise designs and generate prototypes more quickly and accurately. At INFINITIA, we use 3D laser scanning to digitise mechanical and structural parts, enabling us to generate accurate CAD models that serve as the basis for the development of new products or the optimisation of existing designs.

- Rapid prototyping: 3D laser scanning is an essential technology in additive manufacturing and rapid prototyping, enabling physical parts to be scanned and prepared for 3D printing. This workflow reduces development time and accelerates design iteration, optimising component validation prior to series production. At INFINITIA, we use 3D scanning to improve our processesproduct development , ensuring that prototypes meet dimensional and functional specifications before final manufacture.

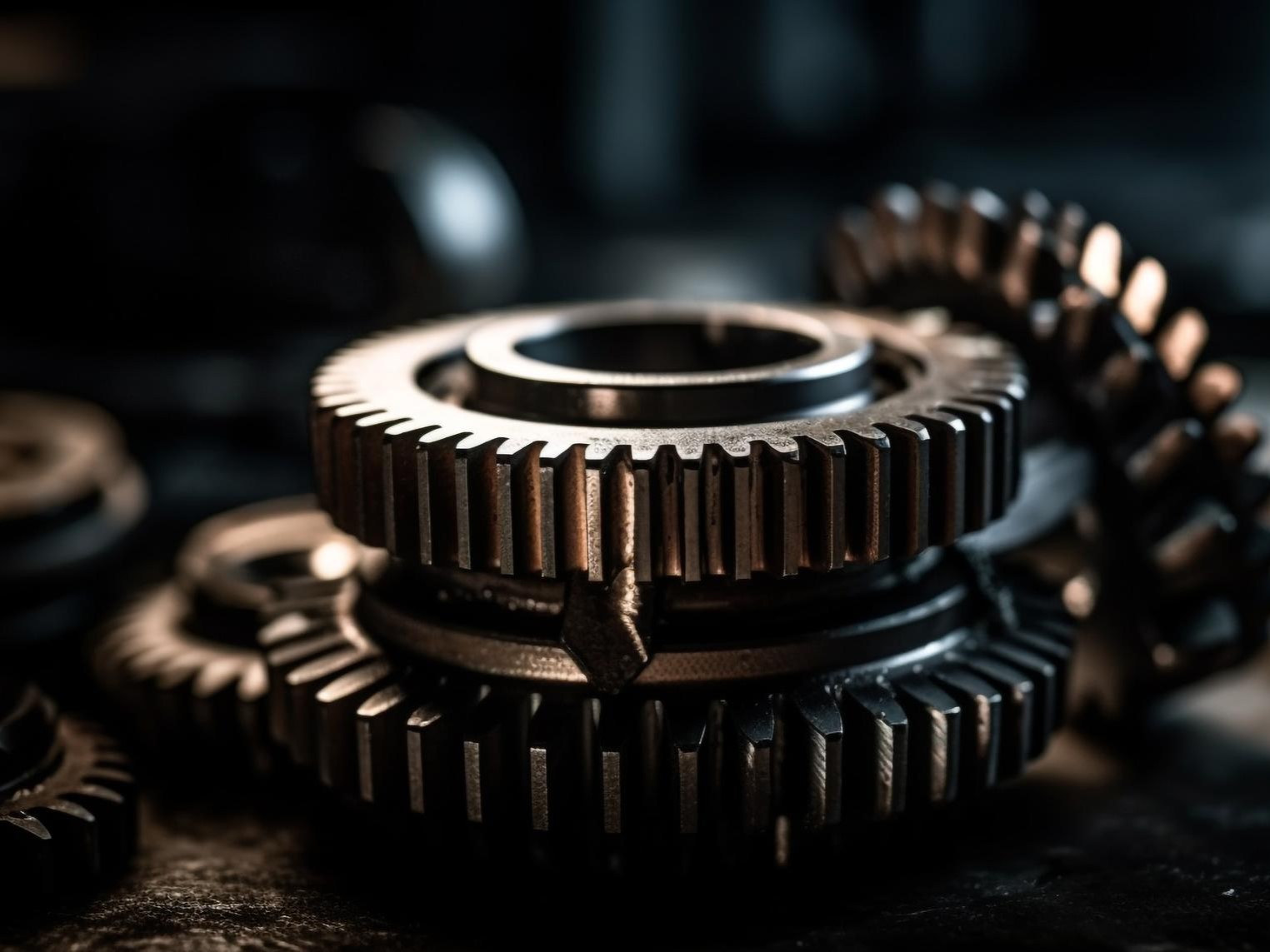

- Inspection of mechanical parts: The use of the 3D laser scanner in the inspection of mechanical parts is essential for assessing the condition of industrial components and detecting possible structural failures. Thanks to its ability to capture high-resolution surfaces, this equipment allows the wear and tear of parts subjected to extreme working conditions to be analysed. At INFINITIA, we apply this technology to the inspection of gears, turbines and other critical components, ensuring their correct operation and prolonging their useful life through detailed wear and deformation analysis.

- Wear and deformation analysis: One of the great benefits of high-precision 3D scanning is its ability to analyse mechanically stressed parts and detect deformation with high accuracy. In industries such as aerospace and automotive, laser scanning is key to assessing material fatigue and predicting structural failure. At INFINITIA, we use 3D scanning to study the evolution of materials under conditions of prolonged use, optimising designs to improve their strength and durability.

- Additive manufacturing and manufacturing: 3D scanning is an essential technology in modern manufacturing, as it allows the digitisation of parts for their reproduction using 3D printing or CNC machining techniques. It also enables the re-engineering of components, facilitating their replication without the need for original drawings. At INFINITIA, we apply 3D scanning to optimise manufacturing processes, ensuring that each part is produced with maximum precision and reducing material waste.

Spare Part Manufacturing for Discontinued Components: One of the most valuable applications of 3D laser scanning is the ability to reproduce industrial parts that are no longer manufactured or for which technical drawings are unavailable. By scanning the original geometry, a 3D point cloud is generated, allowing for the creation of an accurate CAD model ready for additive manufacturing or machining. At INFINITIA, this technique enables us to offer customized solutions for the replacement of obsolete components, particularly in areas such as industrial maintenance, classic automotive parts, or specialized machinery—sectors where spare part availability can be a critical factor for operational continuity.

Reverse Engineering and Product Development: High-precision 3D scanning is a fundamental tool in reverse engineering, enabling the capture of detailed geometry from existing products for analysis, redesign, or improvement. Once digitized, components can be functionally adapted, structurally optimized, or used to create customized versions of the original design. At INFINITIA, we apply this methodology as part of our comprehensive product development process. Using the Creality Raptor X, we combine physical part digitization with CAD design and advanced manufacturing techniques to deliver innovative, functional, and industry-aligned solutions

The high-precision 3D laser scanner is a key tool for three-dimensional digitization, quality control, and rapid prototyping. Its ability to capture complex geometries with great accuracy makes it a versatile and precise solution for analyzing industrial components in sectors such as automotive, engineering, and advanced manufacturing.

At INFINITIA, the Creality Raptor X model is used to develop solutions that demand high reliability in 3D modeling. It is applied in both wear and deformation analysis and computer-aided design (CAD) workflows. This equipment enables us to deliver high-quality, industry-compliant results to our clients.

We show you some examples of the high precision 3D laser scanner at INFINITIA: