¿Qué es la máquina de moldeo por inyección?

The injection moulding machine is a key piece of equipment in the manufacture of plastic parts and components from polymeric materials. Its operation is based on the injection of molten material into a mould with the desired shape, where it cools and solidifies to obtain a final product with high dimensional accuracy.

This process is widely used in industry due to its ability to produce parts in large volumes with precise control over the physical properties ,of the material and at very competitive costs.

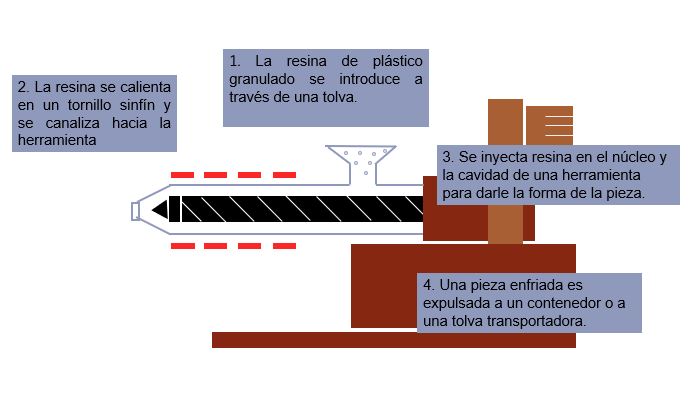

How does injection moulding work?

The injection moulding process follows a series of steps that ensure the quality of the final product. First, the specific thermoplastic material or compound is heated to its melting point. Then, the machine injects the material into the mould at high pressure, ensuring that it is evenly distributed throughout the cavity. The mould is then cooled to solidify the part and finally the finished product is ejected.

This process can include adjustments to parameters such as temperature, injection pressure and cycle times, allowing manufacturing to be optimised according to the needs of the product.

Efficient quality control and testing is key in this process. Moulding parameters must be accurately adjusted to avoid defects such as shrinkage, deformation or bubbles, which can compromise the functionality of the part. For this purpose, modern machines are equipped with real-time monitoring systems, which allow automatic adjustments to be made to improve the stability of the process.

Benefits of the injection moulding machine

One of the main benefits of the injection moulding machine is its ability to ensure high repeatability and accuracy in part production, making it ideal for sectors such as automotive, electronics, medical and packaging manufacturing.

In addition, this method allows the optimisation of the material used, reducing waste and production costs, making it an efficient and sustainable solution for the industry.

It also enables the use of recycled materials and biodegradable polymers, contributing to more sustainable practices within industrial manufacturing.

Injection moulding machine equipment

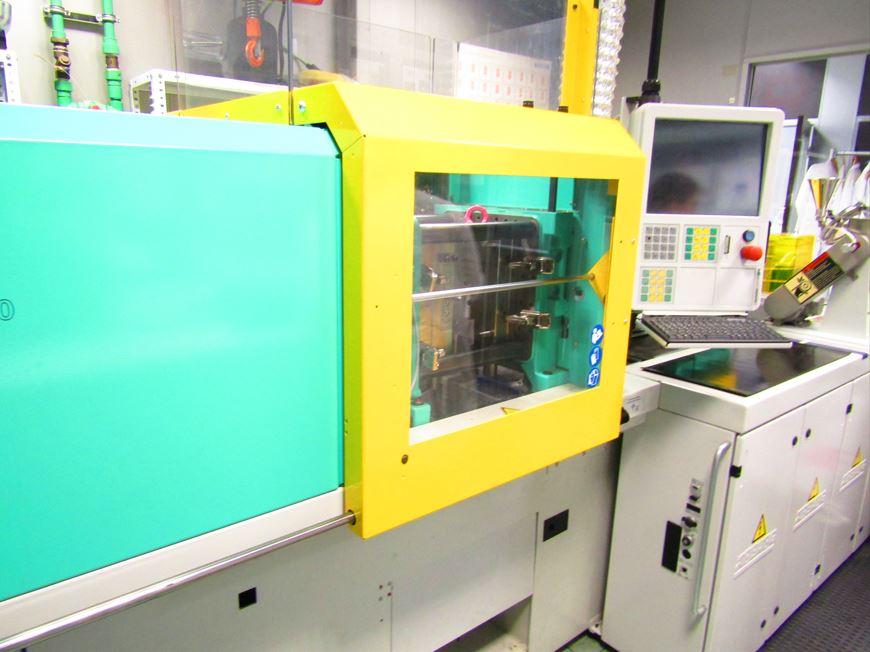

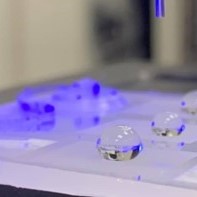

The Arburg Allrounder 270 S 400-70, used at INFINITIA, is a high-precision injection moulding machine designed for the production of samples for material characterisation and mechanical testing.

It features a 400 kN clamping force and an injection unit optimised for processing technical polymers and advanced composites. Its Selogica-based control system allows key parameters such as injection pressure, speed and cycle times to be adjusted, ensuring stable and repeatable production.

This equipment complies with , which regulates the safety requirements for plastic injection moulding machines, ensuring safe and efficient operation in industrial environments.

Thanks to its precision and versatility, this equipment is a fundamental tool in the development of new materials and in the validation of industrial processes

Equipment applications

Injection moulding is a widely used process in various industries due to its ability to produce parts with high precision and in large volumes.

In the field of materials developmentresearch and , this technology is essential for the production of samples for various types of studies. Among its most relevant applications are:

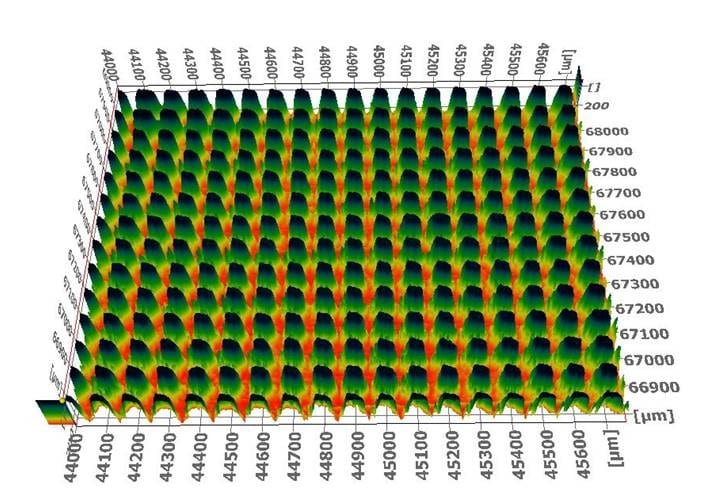

- Injection moulding for surface characterisation: Allows parts to be manufactured with specific finishes in order to study their physical properties, evaluate their texture and determine their behaviour in the face of surface treatments.

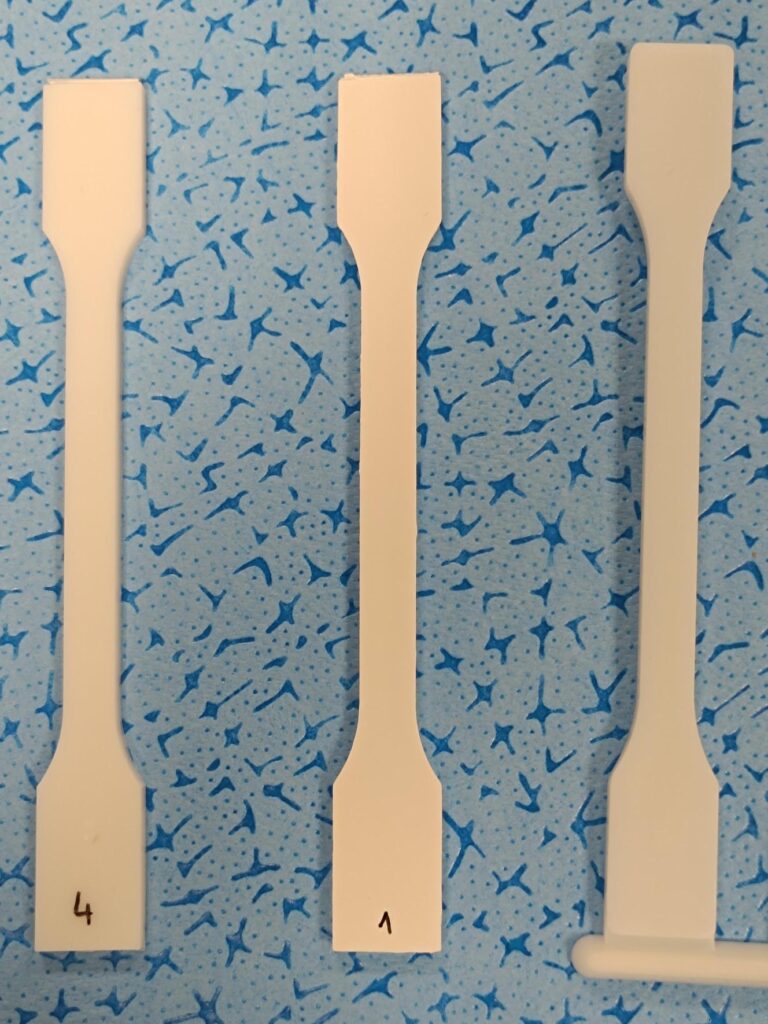

- Injection moulding of samples for mechanical characterisation: This process is essential in the manufacture of samples for testing mechanical properties such as tensile strength, impact and hardness.

- PIM (Powder Injection Moulding) studies: Powder Injection Moulding (PIM) is an advanced technique used in the manufacture of components with metallic or ceramic powders combined with a polymeric binder.

- Development of new materials and plastic formulations: The equipment allows experimentation with different polymers, additives and the creation of surface finish modifications using IMM (in mould microstructurationtechnology) , optimising their properties for their application in different sectors to create materials with new, more resistant, lighter and sustainable properties.

- Quality control and testing in the manufacturing industry: Injection moulding is essential in the production of parts that must meet strict quality standards. Approval tests, failure analysis and studies on the physical and mechanical properties of the materials used are carried out.

- Injection moulding in the automotive industry: In the automotive sector, this technology is used to manufacture components such as interior panels, electronic device housings and structural parts.

- Injection moulding in medical devices and pharmaceuticals: Injection moulding is used in the production of medical devices such as syringes, prostheses, packaging and components for diagnostic equipment.

- Recycling and sustainability in injection moulding: One of the most relevant trends in the industry is the use of recycled plastics and biodegradable polymers in the injection moulding process.

- Process optimisation and energy efficiency: The modernisation of injection moulding machines has led to the incorporation of real-time monitoring systems, automation and advanced quality control.

The injection moulding machine is an essential piece of equipment in the manufacture of samples and industrial parts with a high level of precision. Its application in surface characterisation, plastics testing and material studies makes it an essential tool for research, product development and quality control in multiple sectors.

At INFINITIA, this equipment is used to ensure that the materials manufactured meet the highest standards of quality and performance. From forensic engineering for failure prevention, to optimising production processes, to product improvements innovation and to create new functional surfaces, injection moulding is key to creating innovative solutions in the industry.

We show you some examples of the use of the injection moulding machine at INFINITIA:

New materials through surface finish modifications in plastics