What is a marking laser?

A marking laser is a cutting-edge technology used to permanently engrave codes, logos, text or patterns onto a wide variety of surfaces, from metals and polymers to ceramics and composite materials.

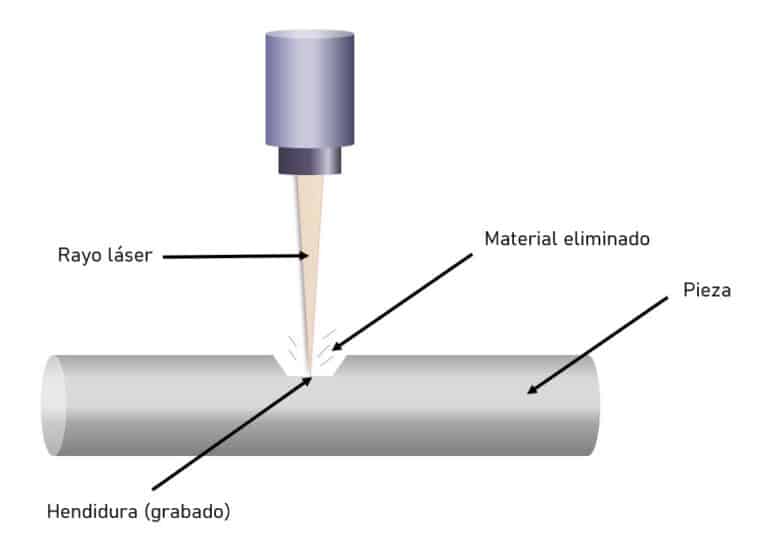

This technique is based on the emission of a highly concentrated laser beam, which interacts with the surface of the material causing a localised physical or chemical modification.

Thanks to its precision, cleanliness and ability to adapt to complex geometries, laser marking has become an essential tool in sectors that require traceability, customisation or identification of technical parts.

Its use is key in industries such as automotive, aerospace, electronics, medical devices and packaging, where markings must withstand wear, abrasion and chemicals.

In this context, INFINITIA is committed to incorporating this technology as part of its commitment to innovation, product and process improvement, offering solutions tailored to industrial development needs.

How does laser marking work?

The laser marking process begins with the generation of the beam by a laser source, such as a fibre laser or an ultra-short pulse laser.

This beam is focused with specific lenses onto the target area and, depending on the energy and duration of the pulse, can generate different effects: from a simple surface colour change to controlled ablation of the material.

The laser interacts with the surface through thermal or photochemical processes, allowing for contactless, high-resolution marking without damaging adjacent areas.

In advanced applications, such as those developed in INFINITIA’s laboratories, this principle is combined with micro and nano structuring techniques, oxidation control or coating removal, adapting the parameters to each case.

The equipment is operated by high-precision control systems that allow processes to be automated, integrated with other production phases or customised designs to be applied, ensuring repeatable results with minimal tolerances.

Benefits of laser marking

One of the biggest benefits of laser marking is its versatility. Unlike conventional methods such as mechanical engraving or ink labelling, lasers allow permanent marking without adding materials or generating waste.

This makes it a sustainable, clean and accurate solution. It also offers extremely high resolution, ideal for Datamatrix codes, serial numbers, logos or microtext, even on irregularly shaped parts.

This type of technology improves product traceability, safety and quality control, facilitating identification throughout the supply chain.

In sectors such as the automotive industry, where durability and reliability standards are strict, laser marking has proven its effectiveness in both validation processes and mass production.

INFINITIA incorporates this technique into its commitment to innovation, applying it to advanced development projects and functional material analysis.

Laser marking equipment

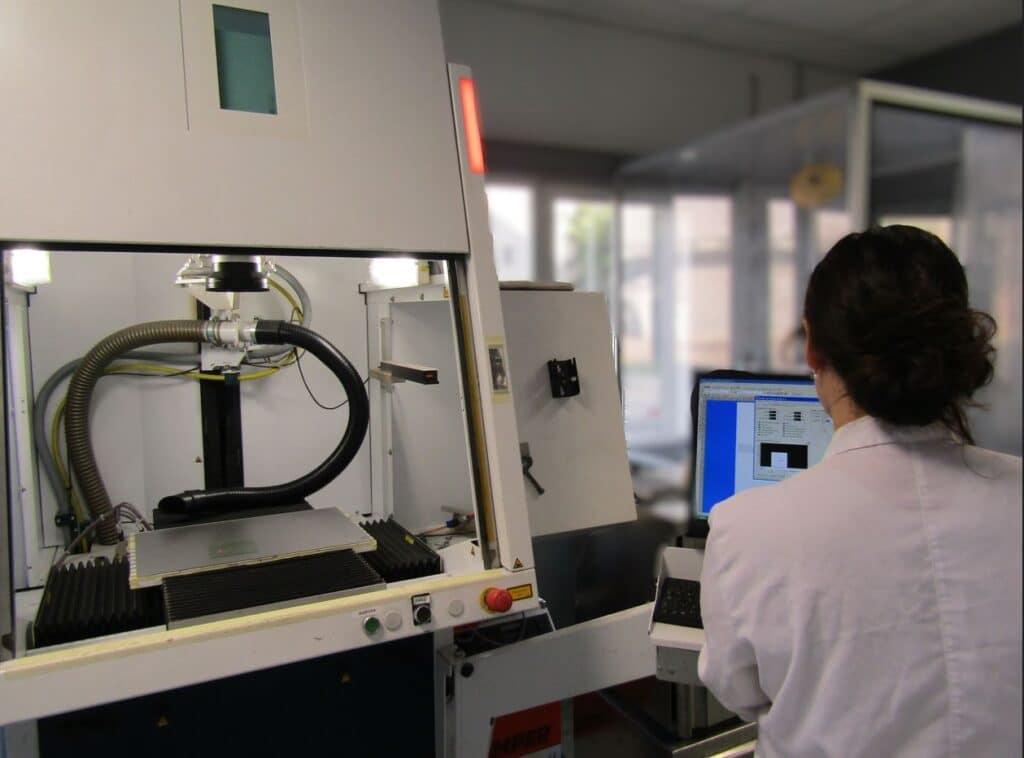

At INFINITIA, we have the Laser TRUMPF 5020 equipment, an infrared fibre laser system with a power of 20W, MOFPA technology and adjustable pulses between 9 and 200 nanoseconds.

This model is capable of operating at frequencies of up to 1000 kHz, allowing great control over the effects of the laser on different materials. The versatility of the TRUMPF 5020 makes it an ideal tool for multiple processes, mainly decorative or functional marking, although depending on the material it can also be used for micro-perforation, laser cleaning, paint removal and micro/nano structuring to modify surface properties.

Its design complies with the safety requirements established by ISO 11553-1:2020, which regulates the safe use of laser machines in industrial and laboratory environments, ensuring personnel protection and system operational reliability.

Compared to other models on the market, its ability to work on parts up to 600x600x400 mm and its compatibility with complex geometries position it as a benchmark in advanced applications.

At INFINITIA, this equipment is integrated into technological development projects, material analysis and solution validation, guaranteeing high-precision results tailored to customer needs.

Applications of the Marking Laser

The marking laser has established itself as an essential tool in many industrial and scientific sectors thanks to its versatility, precision and ability to generate permanent results without contact.

At INFINITIA, the use of marking laser equipment allows us to tackle a wide variety of technological challenges, offering customised solutions that combine functionality and traceability.

The most relevant applications of this equipment in the laboratory environment and in industrial contexts are described below.

- Marking for traceability and identification: One of the most common applications of laser marking is the permanent identification of components using alphanumeric codes, logos, Datamatrix or QR codes. This traceability is essential in sectors such as automotive, aerospace and pharmaceuticals, where each part must be tracked throughout its entire life cycle. At INFINITIA, we use this capability to validate manufacturing processes and ensure that materials comply with the most demanding technical standards.

- Decoration and aesthetic marking: Laser marking allows decorative markings to be applied with high resolution and an excellent surface finish. This is particularly useful for products that combine functionality and aesthetics, such as electronic components, medical instruments or consumer devices. By controlling the pulse frequency and energy, it is possible to generate complex visual effects without altering the structure of the material. This application is a clear example of the added value that technology , innovation or product design.

- Laser cleaning and passivation: Marking lasers can also be used to selectively remove oxides, impurities or surface coatings without damaging the substrate. This process, known as laser cleaning, is highly valued in the preparation of surfaces for subsequent treatments, such as welding or adhesives. In addition, lasers can be used to passivate metal surfaces, creating protective layers that increase corrosion resistance. At INFINITIA, we use this technology both in product development to give materials new functionalities and in failure analysis to study different behaviours in response to lasers and adjust processing parameters.

- Cutting and microperforation: Thanks to its configuration and precision, the marking laser can perform fine cuts and microperforations on technical materials, especially polymers and thin sheets. This type of application is essential in the manufacture of electronic devices, microcomponents and filter membranes. At the INFINITIA laboratory, we carry out this work as part of material innovation testing, where high resolution is required without generating thermal stresses on the part.

- Selective paint removal and ‘day & night’ effects: Laser marking is an ideal solution for the controlled removal of surface layers such as paint or coatings, creating dual visual effects known as day & night, which are widely used in the automotive industry (backlit button panels) and electronics. This technique allows parts to be customised according to lighting conditions or use, without resorting to aggressive chemical processes. At INFINITIA, this application is part of functional validation and coating durability analysis projects.

- Laser welding of polymers: The TRUMPF 5020 marking laser is also used in laser welding of polymers processes, enabling clean, precise and contact-free joints. At INFINITIA, we use it to weld plastic parts through selective absorption, achieving strong joints without the need for adhesives or mechanical elements. This technique is particularly useful in sectors such as automotive and electronics, where tightness and compatibility between materials are required. The joints are validated through thermal, optical and mechanical analyses, ensuring reliable and repeatable results.

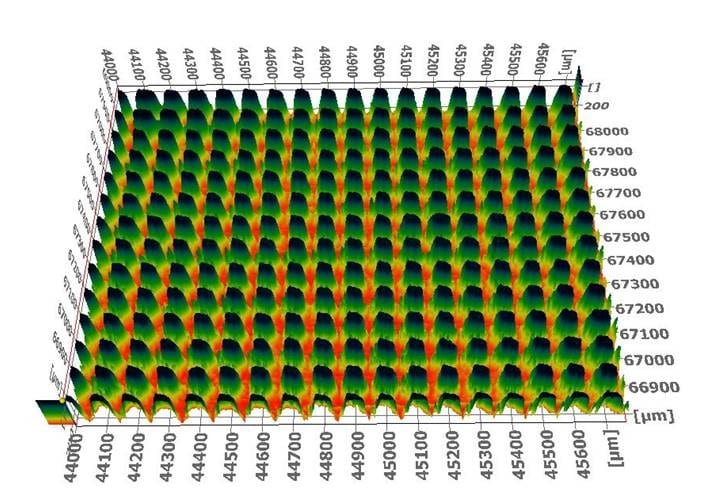

- Surface micro/nanostructuring: One of the most advanced capabilities of laser marking is the ability to induce micro and nanostructures on the surface of a material. These structures modify properties such as roughness, contact angle or reflectance, which is key in the development of functional surfaces: self-cleaning, antibacterial or with specific optical properties. INFINITIA uses this technique in R&D projects linked to sectors such as health and food.

- Controlled oxidation: Lasers can be used to induce controlled oxidation on the surface of metal, generating specific colours or layers with improved properties. This localised thermal oxidation not only has aesthetic value, but can also improve the adhesion of subsequent coatings or serve as passive protection. These types of treatments are applied by INFINITIA in contexts where functionality and chemical resistance must be combined.

- LIFT (Laser Induced Forward Transfer): The equipment can also be used in advanced techniques such as Laser Induced Forward Transfer (LIFT), which allows micro-quantities of materials to be deposited on specific substrates. This technique is widely used in printed electronics, bioprinting and flexible sensors. Its precision and non-contact nature are ideal for transferring functional inks, conductive polymers and biomaterials. INFINITIA works on this application within technology and innovation projects applied to new materials.

Laser marking has established itself as an indispensable tool in laboratory and industrial environments thanks to its versatility, precision and ability to generate permanent, clean and contactless results.

Its integration into traceability, microstructuring, surface cleaning and functional modification processes makes it a key ally in the development of advanced technical solutions.

Equipment such as the TRUMPF 5020 takes these capabilities to the highest level, thanks to its fine control of parameters and its compatibility with a wide range of materials and geometries.

At INFINITIA, laser marking is part of a strategy focused on technical excellence and innovation in materials, both in applied research and laboratory services.

Its use allows us to tackle complex projects that require extreme dimensional control, surface customisation or functional validation tests. In addition, this equipment offers us the possibility of designing unique, efficient and environmentally friendly processes, in line with current sustainability and industry challenges.

Looking ahead, advances in technologies such as ultra-fast laser marking, integration with artificial vision systems and functional printing using techniques such as LIFT, promise exponential growth in their applications. In this context, INFINITIA will continue to invest in these technologies, integrating analytical capabilities, functional design and industrial vision into a single value proposition.

At INFINITIA, we remain committed to innovation and the use of advanced technology in our laboratories to deliver accurate, high-quality results. Thanks to our team of specialists, experience and state-of-the-art equipment, we guarantee efficient solutions tailored to the needs of the industry.

Here are some examples of fast laser marking at INFINITIA:

New materials through modifications to the surface finish of plastics