What is a metallographic microscope?

The metallographic microscope is an essential analytical tool for the study of metallic materials, designed to observe and analyse the internal microstructures of metals.

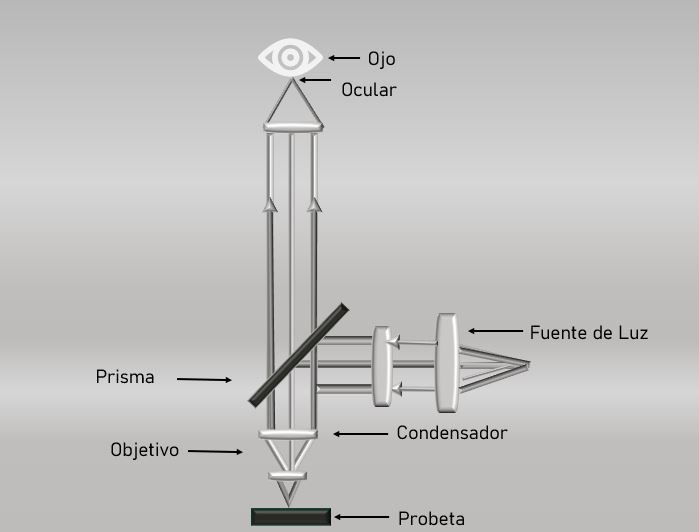

This equipment uses optical microscopy techniques to examine the arrangement of grains, phases and possible defects present in metal samples. It works by reflecting light onto the polished surface of the sample, allowing clear and detailed images of the structural features of metals to be obtained.

These observations are fundamental to understanding the physical properties of materials, helping to improve their design and performance in specific applications.

How does the metallographic microscope work?

The operation of the metallographic microscope begins with meticulous sample preparation. This includes precise cutting, resin mounting and polishing, followed by chemical or heat treatments depending on the needs of the analysis.

Once prepared, the sample is placed under the microscope, where it is illuminated with reflected light. Structural details are captured using high-resolution lenses and analysed using specialised software. This process identifies characteristics such as metallic phases, microstructure uniformity and the presence of defects, such as cracks or inclusions, which could compromise the material’s performance.

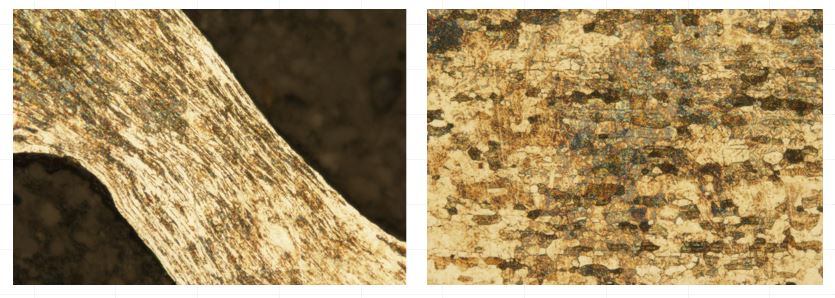

Interpretation of the results obtained with a metallographic microscope involves visual analysis of the captured images. Basic steps include observation of internal structures, identification of metallic phases and measurement of grain sizes and defects. This data is compared to industry standards or project-specific requirements to assess the quality of the material.

In addition, many models include options for capturing and storing images, allowing for comparative analysis and accurate documentation of the data obtained, which is crucial in scientific research and quality control processes.

Benefits of metallographic microscopy

A key benefit of the metallographic microscope is its ability to provide detailed, non-destructive information on the quality and physical properties of materials. This allows engineers and scientists to optimise manufacturing processes, select suitable materials and ensure that final products meet the required quality standards.

In addition, its versatility to analyse a wide range of metallic materials makes it an indispensable tool for the automotive, aerospace, construction and advanced research industries.

Metallographic microscope equipment

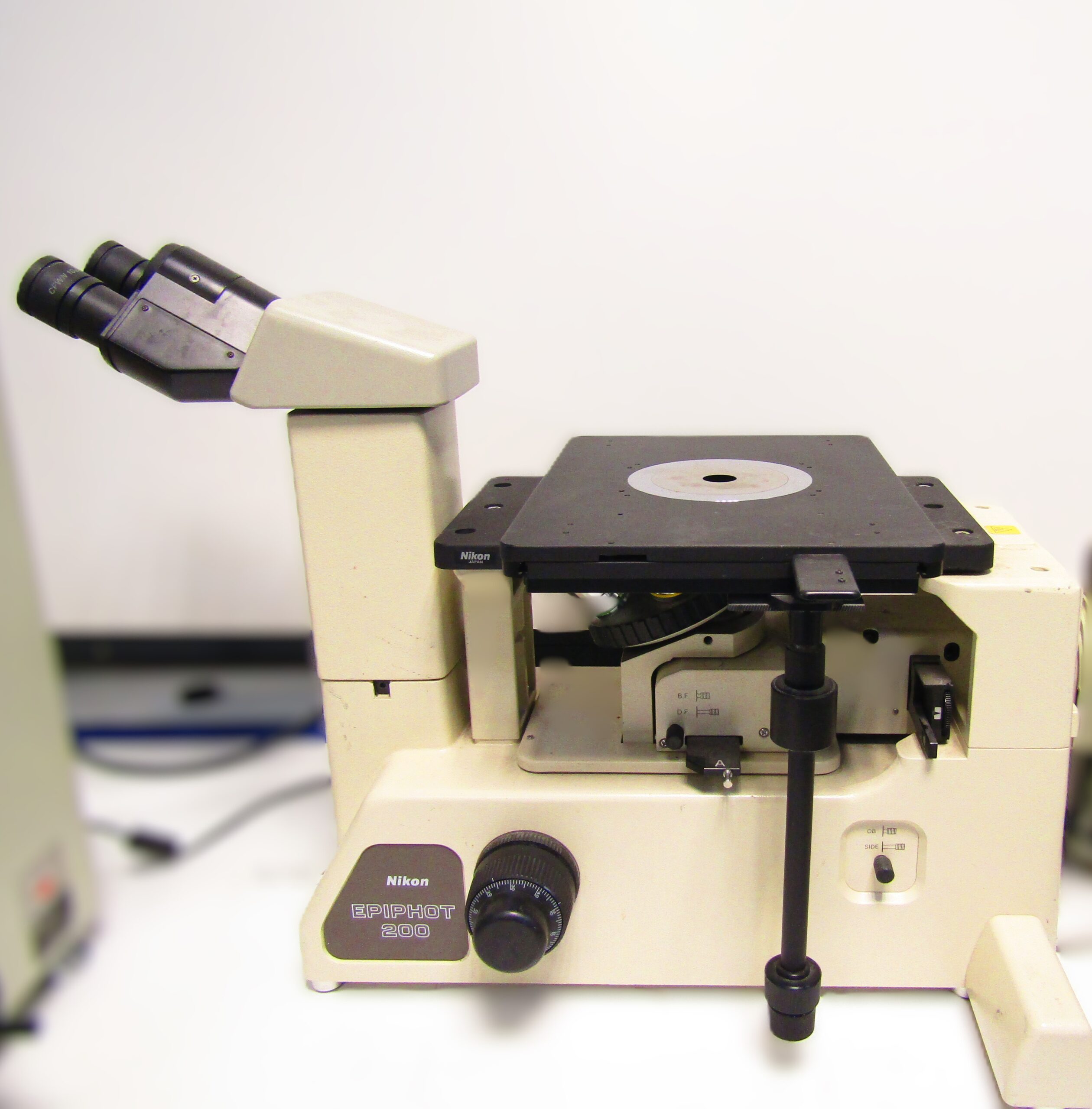

The Nikon Epiphot 200 , used at INFINITIA, is a high-precision metallographic microscope designed specifically for the detailed analysis of metallic microstructures. This model features an advanced optical system including high-resolution lenses and adjustable epi-vertical illumination, ideal for observing polished and chemically treated surfaces. In addition, its ability to integrate digital cameras allows high-quality images to be captured for detailed analysis and documentation.

The Epiphot 200 is equipped with a wide range of objectives that facilitate the study of microscopic features such as grains, phases and defects, adapting to various industrial and scientific needs. Its robust construction and ergonomic design ensure an efficient and comfortable user experience, making it an indispensable tool in quality control laboratoriesand advanced materials development.

Equipment applications

The metallographic microscope has a wide variety of applications in different industrial and research sectors. The most relevant of these are highlighted below:

- Failure analysis : This equipment allows the identification and characterisation of defective materials , helping to understand the causes of failures in metallic components.

Metal phase analysis: This equipment allows the identification and characterisation of materials present in a metallic sample. This is essential for assessing the composition and physical properties of the material, ensuring its suitability for specific applications.

- Defect detection: With metallographic microscopy, it is possible to detect internal defects such as cracks, inclusions and porosity in materials, such as defect detection and redesign of aluminium conductors . This information is essential to ensure product quality and prevent product failure.

- Corrosion performance evaluation: This equipment is used to study the effects of corrosion on metals , analysing degradation patterns and determining material resistance in aggressive environments. This is crucial in industries such as chemical and petrochemical, where materials are exposed to extreme conditions.

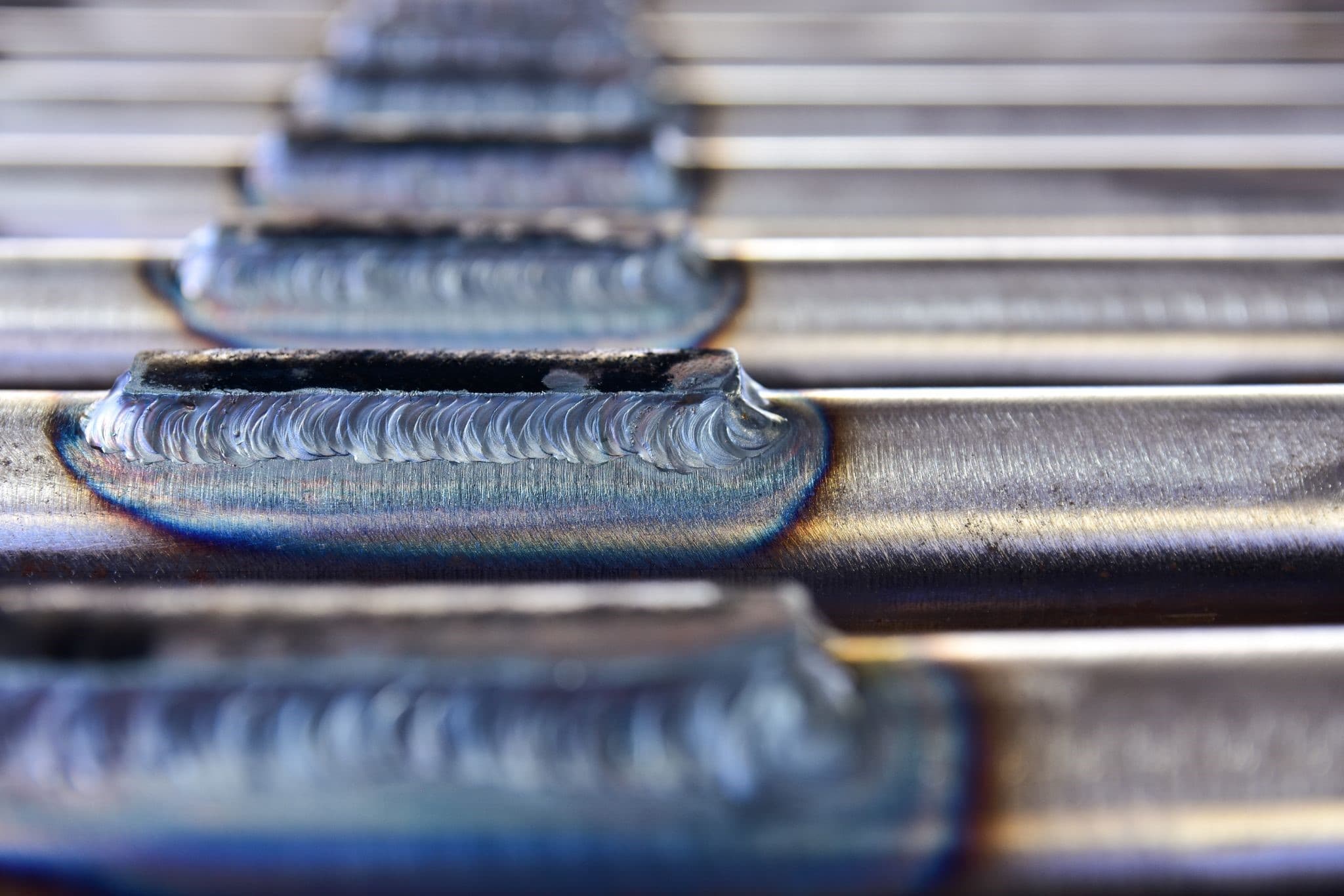

- Characterisation of welds : In the fabrication of metallic structures, metallographic microscopy is used to assess the quality of welded joints . This includes analysis of the weld microstructure and thermally affected zones, ensuring that the joints are safe and durable.

- Quality control in the automotive industry: In the automotive sector, this equipment is used to analyse metal components used in engines, transmissions and chassis, ensuring their strength and durability under intensive use.

- Aerospace research: In the aerospace industry, the metallographic microscope is essential for studying advanced materials, such as light alloys and superalloys, which are used in critical aircraft and spacecraft components.

- Development of advanced metallic materials : In testing laboratories, this equipment is used to analyse new alloys and optimise their physical properties, contributing to technological innovation in various fields.

- Inspection in the construction industry: The metallographic microscope is used to assess the quality of metallic materials such as structural steels and reinforcements, ensuring that they comply with safety and strength regulations.

In conclusion, the metallographic microscope is an essential tool for the detailed analysis of metallic microstructures, playing a crucial role in research and quality control in numerous industrial sectors. Its ability to provide accurate and reliable information on the physical properties of materials contributes to the development of safer, more efficient and durable products.

At INFINITIA, this equipment is used to ensure that the materials analysed meet the highest standards, making it an essential tool for investigators, forensic engineering analysis, and professionals seeking reliable and high quality results in their analysis.

Here are some examples of the use of the metallographic microscope at INFINITIA: