What is the Micro hardness tester?

The micro hardness tester is an advanced instrument designed to measure the hardness of materials at the microscale, a key property in the characterisation of materials and components in sectors such as engineering, metallurgy and electronics.

This instrument is essential in quality control and testing processes, allowing precise evaluation of the mechanical properties of metallic materials and alloys.

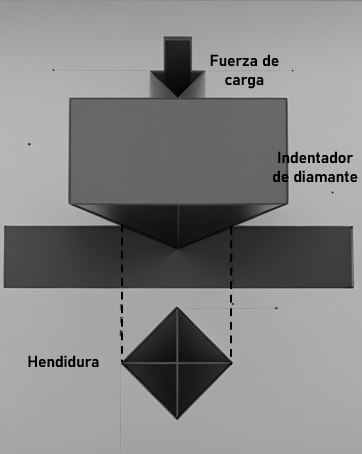

It works by the micro-indentation technique, in which a test tip, usually pyramidal, is pressed into the surface of the material with a controlled force. The size of the indentation left by the tip is accurately measured to calculate the hardness of the material, using standard scales such as Vickers or Knoop. The sensitivity of the microhardness tester allows even the thinnest layers of coatings or thin films to be analysed accurately, providing critical data for research, development of materials approval tests and continuous improvement in advanced materials.

How does the Micro hardness tester work?

The operation of the microhardness tester is based on a controlled loading system and an integrated microscope to measure the indentation generated by the indentation. During the test, the applied force can be adjusted according to the type of material and required standards, ensuring reliable and reproducible measurements. This process is essential in failure analysis and forensic engineering cases, where possible defects or weaknesses in materials subjected to extreme loads or conditions are assessed. The computerised system processes the data in real time and calculates the hardness based on the depth or area of indentation. In addition, the equipment is able to extrapolate parameters such as elastic moduli, providing additional information on the mechanical properties of the material being tested.

Interpretation of the results obtained with a microhardness tester is simple thanks to its integrated software, which generates graphs and tables to facilitate analysis. The process begins with the preparation of the sample, which must be polished and clean to obtain accurate results. Once placed on the equipment platform, the type of load and hardness standard, such as Vickers, Knoop or others, is selected. When the load is applied, the software measures the footprint and automatically calculates the hardness value, which can be compared to the specific requirements of the material or project. This workflow ensures that the data is reliable and ready for immediate use in technical reports or investigations.

Benefits of the Micro hardness tester

A key benefit of the microhardness tester is its ability to make accurate measurements on small or delicate materials, without compromising their integrity. This makes it an essential tool for analysing coatings, thin films and microstructures in sectors where mechanical properties are critical, such as aerospace, automotive and electronics.

In addition, its ability to adjust test conditions, such as load and application speed, ensures results tailored to the specific needs of each failure analysis and testing of metallic materials and alloys.

Equipment of the micro hardness tester

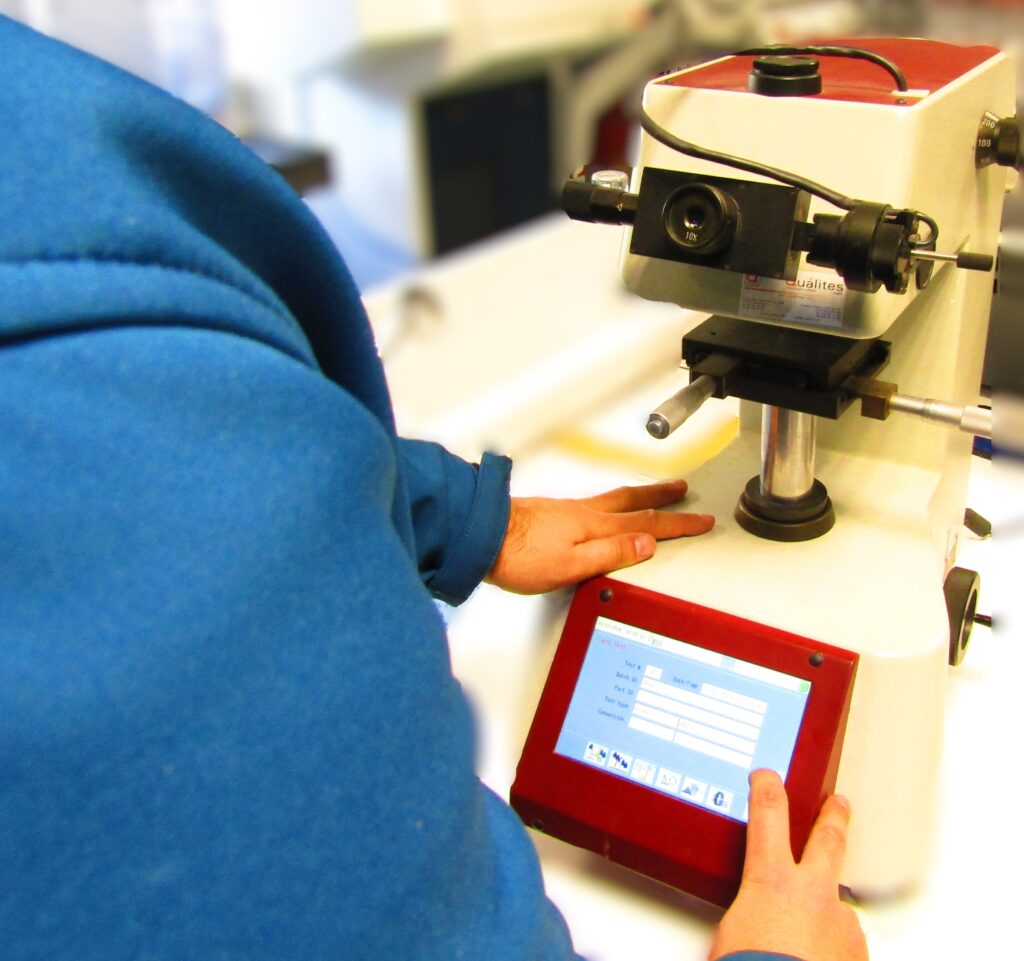

The ISOSCAN OD HV1 model, used at INFINITIA, is a high-precision microhardness tester designed to perform microscale hardness measurements with maximum reliability. This equipment allows working with an adjustable range of test loads from 10 grams to 1 kilogram, which makes it ideal for analysing delicate materials such as thin coatings, as well as more robust samples. Its integrated optical system provides a clear view of the indentation trace, ensuring accurate measurements even on complex surfaces.

In addition, the ISOSCAN OD HV1 incorporates advanced software that automates data analysis, allowing detailed reports to be generated and adapted to international standards such as Vickers and Knoop. Its compact and versatile design makes it an essential tool for laboratories involved in quality control, materials characterisation and materials research.

Equipment applications

The microhardness tester has a wide variety of applications in different industrial and research sectors. The most important of these are described below:

- Material hardness measurement: This equipment is essential for assessing the hardness of metals, alloys, plastics, ceramics and other materials used in the manufacture of components and products. The ability to accurately measure even microstructures allows the properties of different phases or inclusions in composite materials to be analysed.

- Vickers hardness testing and calculation for other standards: Thanks to its versatility, the microhardness tester can test metallic materials and alloys under the Vickers scale and convert the results to other scales such as Brinell or Rockwell, facilitating comparison between different projects and applications. This is especially useful in industries working to international quality standards.

- Load and speed control in testing: The equipment allows the load and application speed to be adjusted according to the material and test specifications. This flexibility is essential for testing sensitive materials or materials with variable mechanical properties, such as advanced polymers and ultra-thin coatings.

- Extrapolation of elastic moduli: In addition to measuring hardness, the microhardness tester can calculate additional parameters such as elastic moduli, which are key indicators of material strength and elasticity. This functionality extends its usefulness in advanced research and new materials development projects.

- Characterisation of coatings and thin films: In sectors such as electronics and optics, the microhardness tester is essential for analysing the mechanical properties of protective coatings and thin films. Its high accuracy ensures reliable measurements on these delicate structures, helping to optimise their design and functionality.

- Metallurgy research: The microhardness tester is a key tool in the failure analysis of metallic microstructures, allowing the study of hardness in different areas of a material, such as welded joints or heat-treated areas. This is essential for quality and safety assurance in critical applications such as construction and automotive.

- Quality control in industrial production: On manufacturing lines, the microhardness tester is used to verify that materials and components meet specified hardness standards. This includes everything from metal parts to plastic components used in electronic products and household appliances.

- Aerospace and automotive applications: These sectors require materials with highly controlled mechanical properties. The microhardness tester enables hardness and other parameters to be analysed on key components, ensuring their performance and reliability under demanding conditions.

- Development of advanced materials: In R&D projects, the microhardness tester is indispensable for characterising new materials and optimising their mechanical properties. This includes special alloys, advanced composites and composite materials, where precision is crucial.

In conclusion, the microhardness tester is an indispensable tool in the characterisation of materials, combining precision, versatility and advanced technology. Its ability to perform microscale measurements positions it as an essential piece of equipment in sectors that demand high standards of quality and performance. At INFINITIA, this equipment is used to guarantee reliable results and support the development of innovative solutions that meet the most demanding standards, to the development of productssafe and quality .

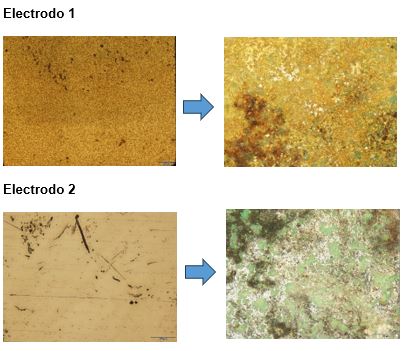

We show you some examples of the use of the microdurimeter in INFINITIA:

Analysis of production failures caused by different batches of galvanised steel components