What is the multi-material wire 3D printer?

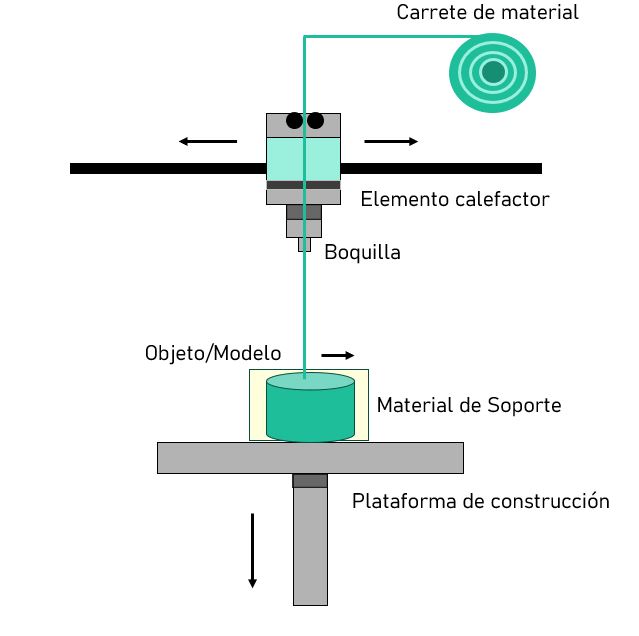

The multi-material wire 3D printer is an advanced additive manufacturing tool that enables the creation of three-dimensional parts by extruding technical polymers. Its operation is based on FDM (Fused Deposition Modeling) technology in ,which a filament of material is melted and deposited layer by layer to form the desired object.

Thanks to its ability to work with multiple materials in a single printing process, this printer offers unprecedented versatility in the manufacture of prototypes, functional parts and custom structures.

How does the multi-material wire 3D printer work?

The operation of this equipment is based on the extrusion of thermoplastic filaments that are heated until they reach their melting point, allowing their controlled deposition on a construction platform.

The 3D printer moves along three axes (X, Y and Z), progressively building the part from a digital model. In its multi-material version, it can alternate between different extruders or use automatic filament changing systems, which allows rigid and flexible, conductive or heat-resistant materials to be combined.

At INFINITIA, we combine this capability with dimensional verification and simulation tools, ensuring that each manufactured part meets the expected functional and aesthetic requirements, even in demanding validation environments such as automotive or advanced electronics.

Benefits of the multi-material wire 3D printer

One of the most outstanding benefits of the multi-material 3D wire printer is its ability to produce complex geometries and structures that would be impossible to produce using conventional manufacturing methods.

This aspect is especially valuable in iterative design and concept validation, allowing engineers and designers to make quick and efficient modifications before final production.

At INFINITIA we have applied this technology in multiple projects, significantly reducing development times and improving product customisation.

Equipment of the multi-material wire 3D printer

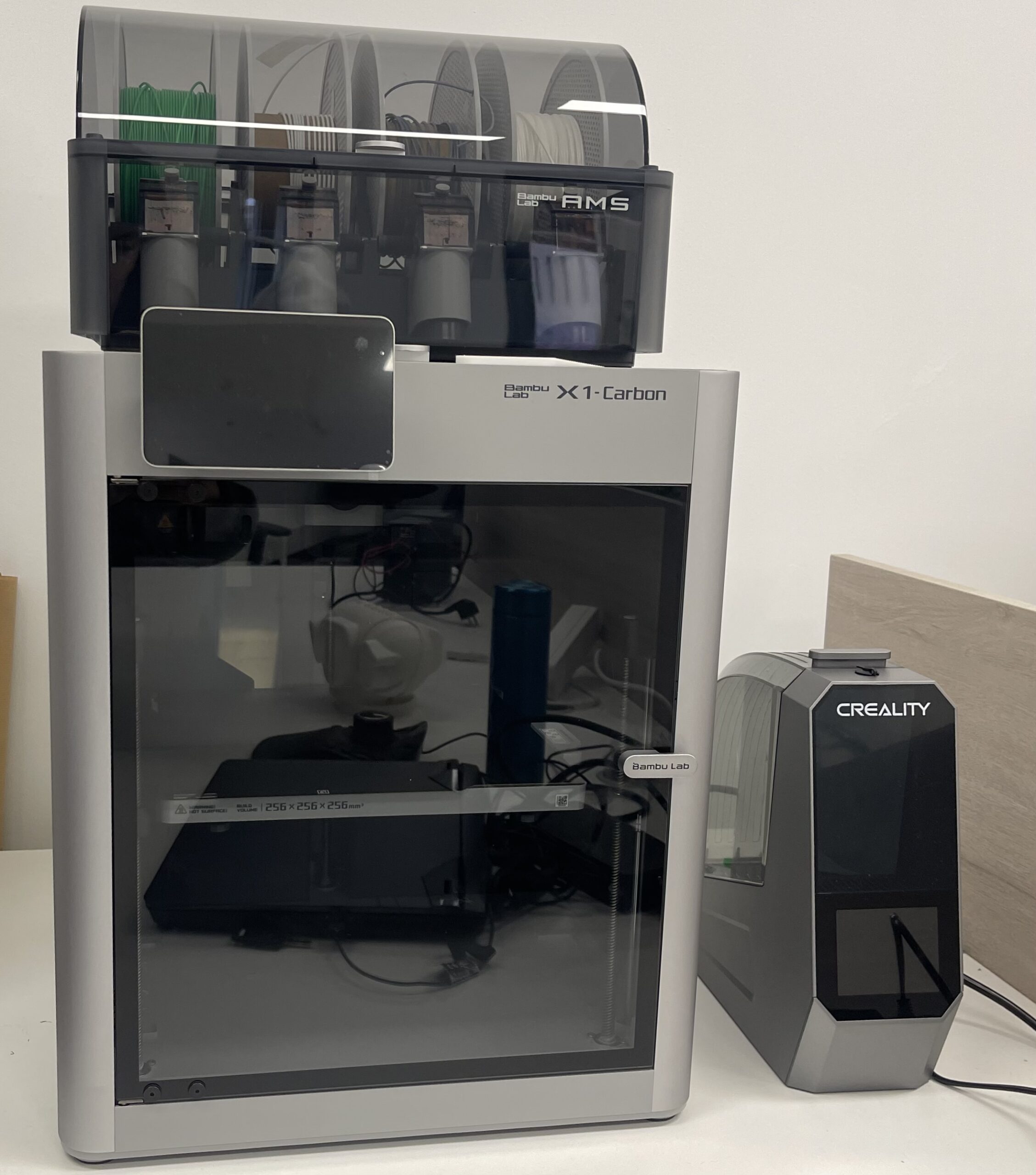

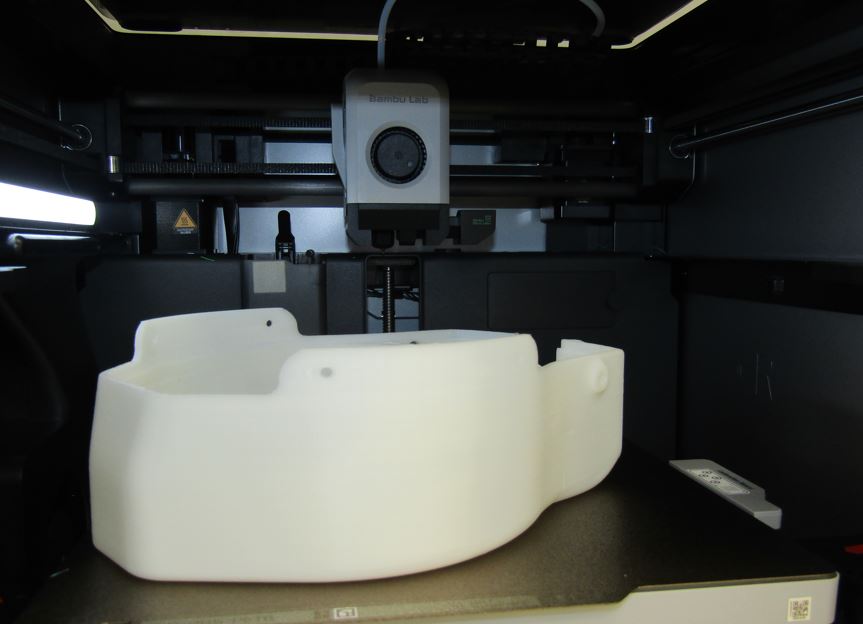

At INFINITIA we have the Bambu X1C, a state-of-the-art printer that stands out for its high precision, printing speed and ability to work with advanced technical materials.

Unlike other models on the market, the Bambu X1C offers an optimised extrusion system that minimises printing errors and ensures excellent adhesion between layers. Its compatibility with a wide range of filaments allows it to be used in demanding applications where mechanical and thermal resistance are key factors.

Thanks to these characteristics, this equipment has become a key part of our laboratory, facilitating experimentation with new technologies and the optimisation of production processes. Its precision and versatility allow us to speed up the manufacture of functional prototypes, validate complex geometries and carry out tests with innovative materials, which contributes to improving products, reducing iteration times and generating advanced solutions adapted to the needs of our customers.

Equipment applications

The main applications of 3D printing include:

- Manufacture of tooling: 3D printing of tooling has revolutionised the way in which specialised tools for production and assembly processes are designed and manufactured. Thanks to the multi-material filament printer, at INFINITIA we can produce customised tooling with materials of high mechanical and thermal resistance, optimising its functionality according to the specific needs of each industry. This allows manufacturing costs and delivery times to be reduced compared to traditional machining or moulding methods.

- Design verification: Before manufacturing a product on a large scale, it is essential to validate its design. With the multi-material filament printer we can create functional prototypes that allow us to check the viability of a design, evaluate its performance and make improvements before final production.

- Manufacture of customised setups: Test and validation setups require specific structures that are adapted to each experiment or test. 3D printing allows these configurations to be manufactured quickly and in a personalised way, ensuring compatibility with laboratory equipment and facilitating the execution of technical tests in sectors such as electronics, biomechanics and robotics.

- Validation of mechanisms: The possibility of printing functional mechanisms with technical materials allows their real behaviour to be evaluated before going into production. At INFINITIA, we use 3D printing for the validation of moving parts, gears and mechanical systems that require high precision and resistance. This process speeds up product development by reducing the need for multiple iterations on more expensive materials.

- Aesthetic validation: In addition to functional testing, 3D printing facilitates the aesthetic validation of products before their launch. At INFINITIA we produce physical models that allow us to evaluate finishes, ergonomics and visual perception, facilitating design adjustments before mass production. This application is especially useful in sectors such as industrial design and consumer goods manufacturing.

- Dimensional verification: The demands for precision in industrial parts require advanced metrology tools. 3D printing allows us to manufacture models with controlled tolerances, facilitating the comparison between theoretical design and final part by means of 3D scanners and laser measurement systems. At INFINITIA, we apply this process in the inspection of critical parts for the aeronautical sector and structural engineering.

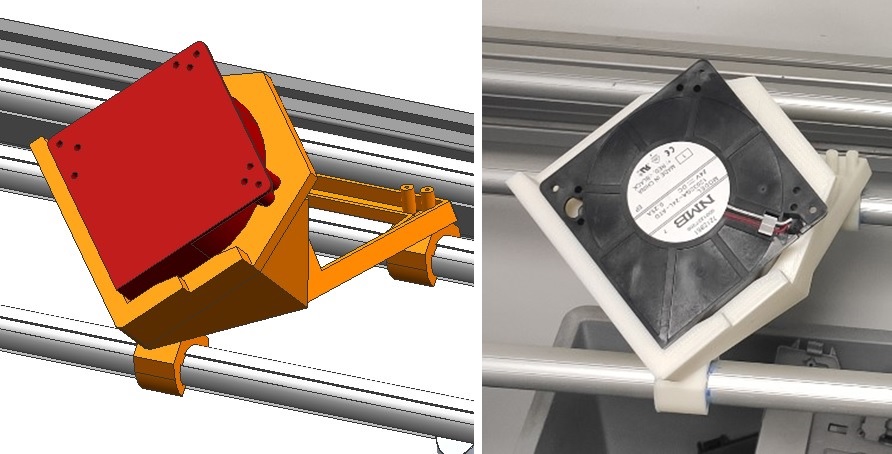

- Adaptation of equipment: Flexibility in the manufacture of customised parts allows existing equipment to be modified to optimise its performance or adapt it to new production needs. At INFINITIA we develop replacement or improvement components for industrial machinery and devices, avoiding dependence on external suppliers and reducing downtime on production lines.

- Low-cost iterative design: One of the most outstanding advantages of 3D printing is the possibility of carrying out multiple iterations of a design without incurring high manufacturing costs. At INFINITIA, we develop functional prototypes with quick and inexpensive changes, which facilitates product optimisation and the implementation of improvements before final production.

- Manufacturing of geometries that cannot be industrialised using conventional processes: The design of parts with complex shapes or optimised internal structures is often a limitation in traditional manufacturing. With the multi-material filament printer of the product development team at INFINITIA, we produce parts with lattice-type structures, internal channels and optimised surfaces that would be impossible to manufacture by machining or injection moulding. This capability opens up new possibilities in advanced materials engineering and the manufacture of lightweight, strong components.

- Proof of concept: Rapid, functional prototypes are crucial for assessing the viability of new ideas and technologies and for carrying out proof of concept. The Bambu X1C allows us to print experimental models in a matter of hours, facilitating the development of innovations in sectors such as biomedicine, flexible electronics and the manufacture of advanced sensors. At INFINITIA, this application is key to the acceleration of R&D&I projects.

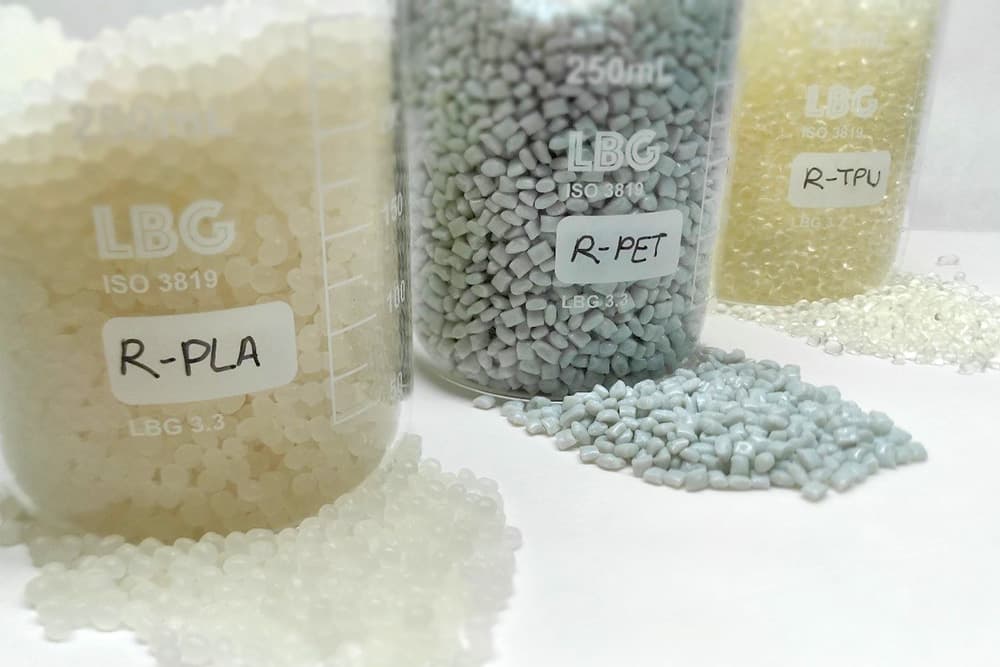

- Testing new technologies: The possibility of working with multiple materials in the same printing process allows the behaviour of new technical polymers and composites to be evaluated in real conditions. At INFINITIA, we experiment with advanced materials, such as filaments reinforced with additives, recycled materials, conductive polymers, exploring their applications in structural engineering and advanced electronics.

At INFINITIA, we have incorporated this technology into our processes to optimise the manufacture of tools, the validation of mechanisms and the development of customised setups.

Thanks to 3D printing, we can reduce production times, minimise costs and improve efficiency in design verification, aesthetic validation and proof of concept testing.

At INFINITIA, we remain committed to innovation and the use of advanced technology in our laboratories to offer accurate, high-quality results. Thanks to our experience and investment in state-of-the-art equipment, we guarantee efficient solutions tailored to the needs of the industry.

We show you some examples of the multi-material wire 3D printer at INFINITIA: