What is a Salt Spray Chamber?

The salt spray chamber is an equipment used to perform accelerated corrosion tests, recreating high salinity environments to evaluate the resistance of materials to aggressive conditions.

This device reproduces a controlled environment by spraying a saline solution, allowing the effects that would normally take years to manifest themselves to be simulated in an accelerated manner.

This type of testing is key in the automotive, marine and protective coatings industries, among others, where durability and corrosion resistance are critical factors.

Its main features include the ability to maintain precise conditions of temperature, humidity and salt concentration, ensuring consistent and comparable results. In addition to salt spray chambers, it is often combined with electrochemical tests and potentiostats in order to obtain a complete characterisation of the materials, evaluation against external agents , or even accelerated tests.

How does the salt spray chamber work?

The operation of the salt spray chamber is simple but effective. The samples to be tested are placed inside the chamber, where they are exposed to the salt spray for a certain time, depending on the type of test and the regulations to be followed, such as ASTM B117 or ISO 9227 .

The equipment uses a system of nozzles to disperse the sodium chloride solution into the environment, creating a continuous mist that is deposited on the surfaces of the samples. Throughout the test, the materials are evaluated for signs of corrosion such as rust, discolouration or wear, which will indicate their resistance under real-life conditions.

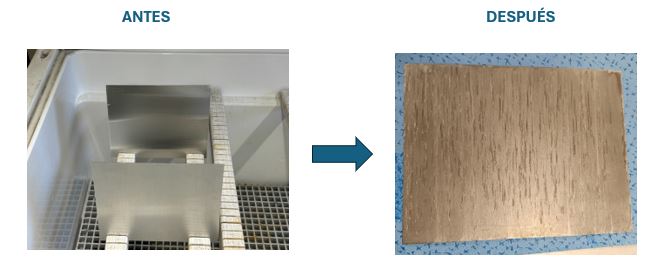

The interpretation of the salt spray chamber results is based on several parameters, such as the exposure time and the degree of visible deterioration of the samples. The typical procedure begins with the preparation of the surfaces to be tested, following strict industry standards. Once the test is completed, the samples are removed and the extent of corrosion damage is analysed.

Depending on the type of material and industry sector, tests may include measuring weight loss, adhesion of coatings, or the appearance of cracks in protective coatings. These results provide valuable information on the durability of the material and its ability to withstand corrosive environments.

Benefits of the salt spray chamber

One of the main benefits of the salt spray chamber is the speed with which it can replicate the effects of corrosion in extreme environments. This allows manufacturers to reduce development and evaluation times for new materials or coatings, optimising their products to be more resistant and durable.

The equipment’s ability to simulate years of exposure in just a few days of testing makes it an essential tool for quality assurance in sectors such as automotive, construction and shipbuilding, where real-life conditions are extremely challenging.

Equipment of the salt spray chamber

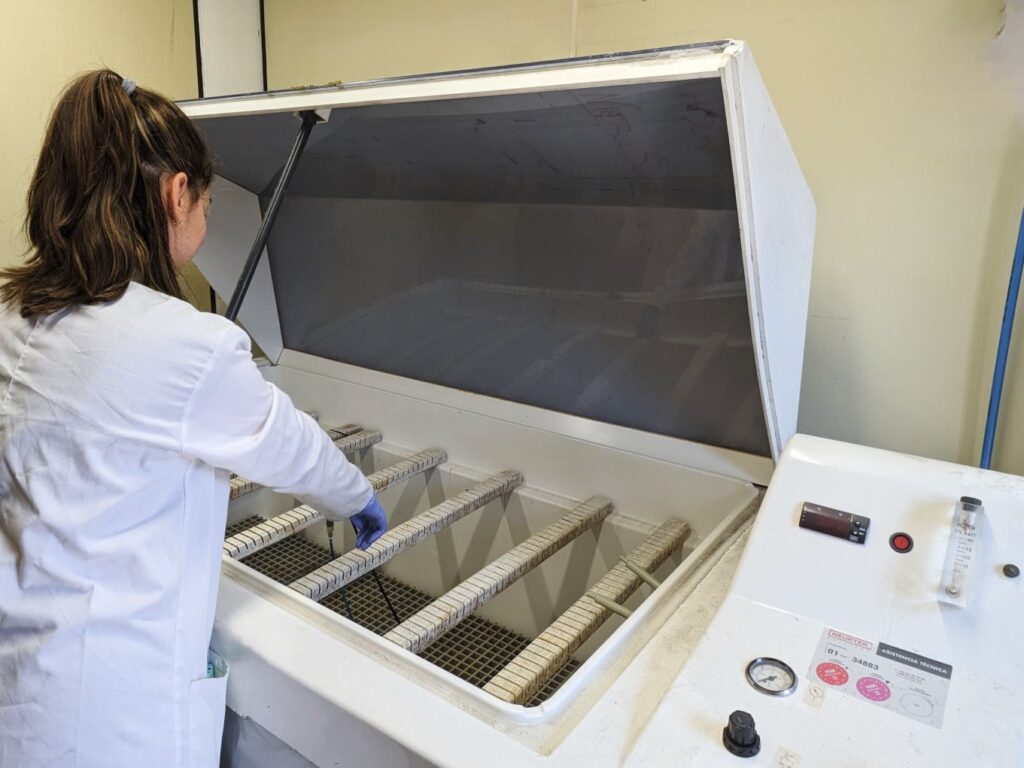

The Dycometal SSC-400 , modelused by INFINITIA, is designed with a series of components that guarantee precise control and efficient operation of the test. It has a control panel with an automaton in charge of managing the test, allowing optimal monitoring and regulation.

In addition, it has a temperature regulator in the tank, ensuring stable conditions throughout the process. For proper water control, it incorporates level indicators on the boiler, while the spraying pressure is kept constant thanks to a specific regulator. The equipment is also equipped with a pressure reducer and a pressure gauge for precise adjustment of the air pressure.

The inner tank is made of fibreglass and polyester resin, materials that make it highly resistant to corrosion and guarantee its durability. Inside, the heating elements are injected directly into the tank, which favours a uniform distribution of the heat, avoiding fluctuations.

For the correct placement of the samples, the equipment has a set of sample-holding bars, allowing an orderly distribution inside the chamber. In addition, a high-precision temperature probe is in charge of constantly monitoring the internal environment, ensuring that the test parameters are appropriate.

The spray system, designed to ensure a homogeneous dispersion of the salt solution, stands out for its low consumption, optimising the efficiency of the process without compromising the quality of the results. This mechanism allows a uniform distribution of the aerosol within the chamber, ensuring that all samples receive equal treatment.

Thanks to its advanced design and quality components, this salt spray tester provides accurate and reliable control of corrosion tests , ensuring consistent and reproducible results. This makes it a versatile solution for quality control laboratories and research , as it complies with international standards such as ASTM and ISO, guaranteeing reliable and globally comparable results.

Equipment applications

The salt spray chamber has prominent applications in a wide range of industrial sectors, where corrosion resistance is a critical factor in product durability. Some of the most relevant applications are described below:

- Accelerated corrosion resistance testing: The main use of this equipment is to subject materials and coatings to extreme corrosion conditions in an accelerated manner. This type of testing is vital in sectors such as automotive and construction, where products must withstand corrosive environments for long periods of time.

- Assessment of surfaces and coatings: The salt spray chamber is used to test the effectiveness of protective coatings applied to metals, such as paints, galvanised and anodised coatings. The tests allow the adhesion, uniformity and durability of these coatings against corrosion to be evaluated, ensuring that the products meet quality and safety standards.

-Testing of galvanising and other surface treatments: Galvanising processes, in which metal is coated with a protective layer of zinc, are crucial to prevent oxidation. The salt spray chamber allows the effectiveness of these processes to be assessed, ensuring that the materials are suitable for use in industrial and marine environments.

- Endurance testing for automotive and aeronautical components: In industries such as automotive and aeronautics, it is essential to ensure that metal parts used in vehicles and aircraft do not suffer premature corrosion. Salt spray equipment is key to assessing the durability of these components, ensuring that they maintain their structural integrity throughout the life of the product.

- Testing in the marine industry: Materials used in ships and boats are constantly exposed to aggressive marine environments. The salt spray chamber is used to simulate these conditions and test how materials react, ensuring that they meet the standards required for use in these environments.

- Accelerated corrosion:resistance testingThis application allows the evaluation of the ability of materials to withstand corrosive environments in a short period of time, simulating years of exposure in just days or weeks.

- Assessment of surfaces, coatings and galvanising: The salt spray chamber ensures that protective coatings applied to materials comply with regulations and provide effective protection against corrosion.

- TCD in saline, acetic and cupric environments: This model allows specialised testing in different corrosive solutions, such as saline, acetic and cupric environments, extending the possibilities of analysis in demanding industrial sectors.

In summary, the salt spray chamber is an indispensable tool in the field of corrosion testing, providing accurate and reliable data for the development and improvement of materials in critical industrial sectors.

With its ability to perform rapid and reproducible tests, this equipment helps to ensure the quality and durability of products in extreme conditions, contributing to the development of stronger and more sustainable materials, making it an essential tool for investigators, forensic engineering analysis and in the investigations of failure analysis .

Here are some examples of the use of the salt spray chamber at INFINITIA: