What is thermogravimetric analysis (TGA)?

Thermogravimetric analysis (TGA) is an analytical technique of vital importance in

materials science and industry. It allows the properties of a material to be studied as a function of temperature and is based on measuring the change in mass of a sample

when it is heated at a controlled rate while exposed to a controlled gas atmosphere.

Through this technique, scientists and technicians can obtain detailed information on

the thermal stability, composition and chemical reactions of materials when

subjected to heat.

TGA is especially useful for identificating the temperatures at which mass changes,

such as decomposition or oxidation, occur. A unique feature of this technique is its

ability to operate under various atmospheres (oxidizing, inert, reducing), which

broadens its applicability to a wide range of studies and materials.

How does TGA works?

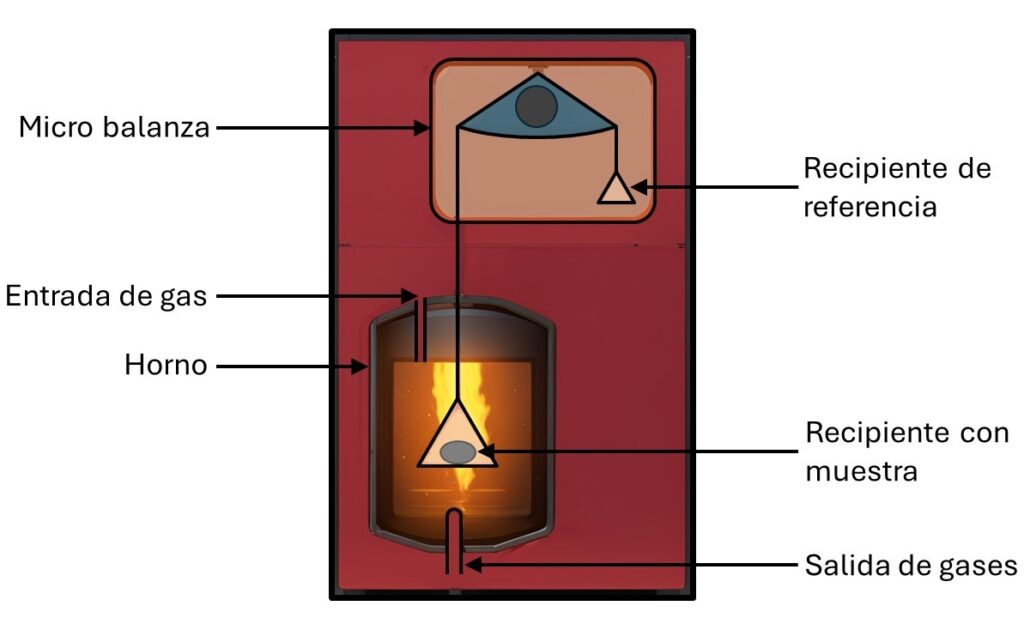

The thermogravimetric analysis (TGA) procedure consists of several key steps that must be followed meticulously to ensure accurate and reliable results. These steps are described in detail below:

- Sample preparation: Initially, the sample to be analyzed is properly prepared. This may include drying, grinding or conditioning in a controlled environment to eliminate any external interference that may affect the results.

- Placement on the balance: Once prepared, the sample is placed on a small, high-precision balance inside the furnace of the thermogravimetric analyzer. This balance is designed to detect minimal changes in the mass of the sample throughout the experiment.

- Controlled temperature increase: The furnace is programmed to increase the temperature in a controlled and gradual manner. The heating rate is selected according to the specific characteristics of the sample and the objectives of the analysis.

- Recording changes in mass: As the temperature increases, any changes in the mass of the sample are continuously recorded as a function of time or temperature. These changes may be due to processes such as thermal decomposition, oxidation, moisture loss, or any other chemical or physical reaction involving a change in mass.

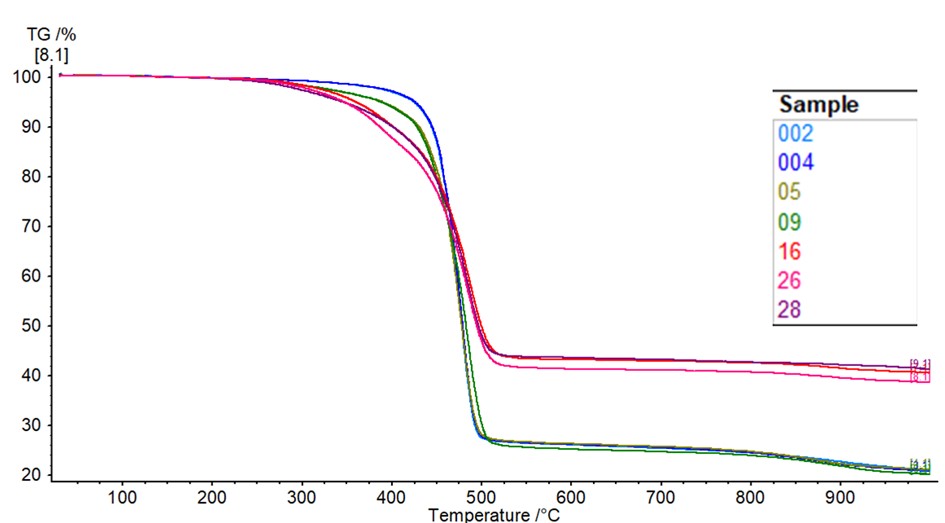

- Analysis of thermogravimetric curves: TGA results are interpreted by analyzing the thermogravimetric curves obtained. These curves show the mass variations as a function of temperature and allow the identification of the different stages of mass loss and the specific temperatures at which these events occur.

- Calibration of the equipment: Before starting the experiment, it is essential to calibrate the equipment to ensure that the measurements are accurate. Calibration includes adjusting the balance and temperature control system to established standards.

- Selection of heating parameters: The appropriate heating parameters for the experiment are selected and set. This includes the heating rate, temperature range and gas atmosphere used (can be inert, oxidizing, etc.).

- Running the experiment: With everything set up and calibrated, the TGA experiment is performed. During this process, the system continuously records mass changes as the sample undergoes the programmed temperature increase.

- Data analysis: Once the experiment is completed, the data obtained is analyzed to draw relevant conclusions. This analysis involves evaluating the thermogravimetric curves, identifying mass loss stages and correlating them with chemical or physical processes occurring in the sample.

- Drawing conclusions: Finally, the results are interpreted and conclusions are drawn about the thermal stability, composition and other relevant aspects of the analyzed material. These results are essential for industrial and research applications.

Benefits of TGA

One of the most prominent benefits of TGA is its ability to provide detailed

information on the composition and thermal stability of materials. This knowledge is

essential in various industries, including plastics, where it is crucial to know the

amount and type of fillers present in the material.

In addition, TGA is extremely useful in the characterization of composite materials,

allowing researchers to determine how these materials behave under heat conditions.

This information is vital for improving product life and safety, and for the development

of new materials with optimized properties. The ability of TGA to evaluate the

resistance to thermal degradation and the stability of materials at different

temperatures makes it an indispensable tool for research laboratories, quality control

and forensic engineering cases.

TGA Equipment

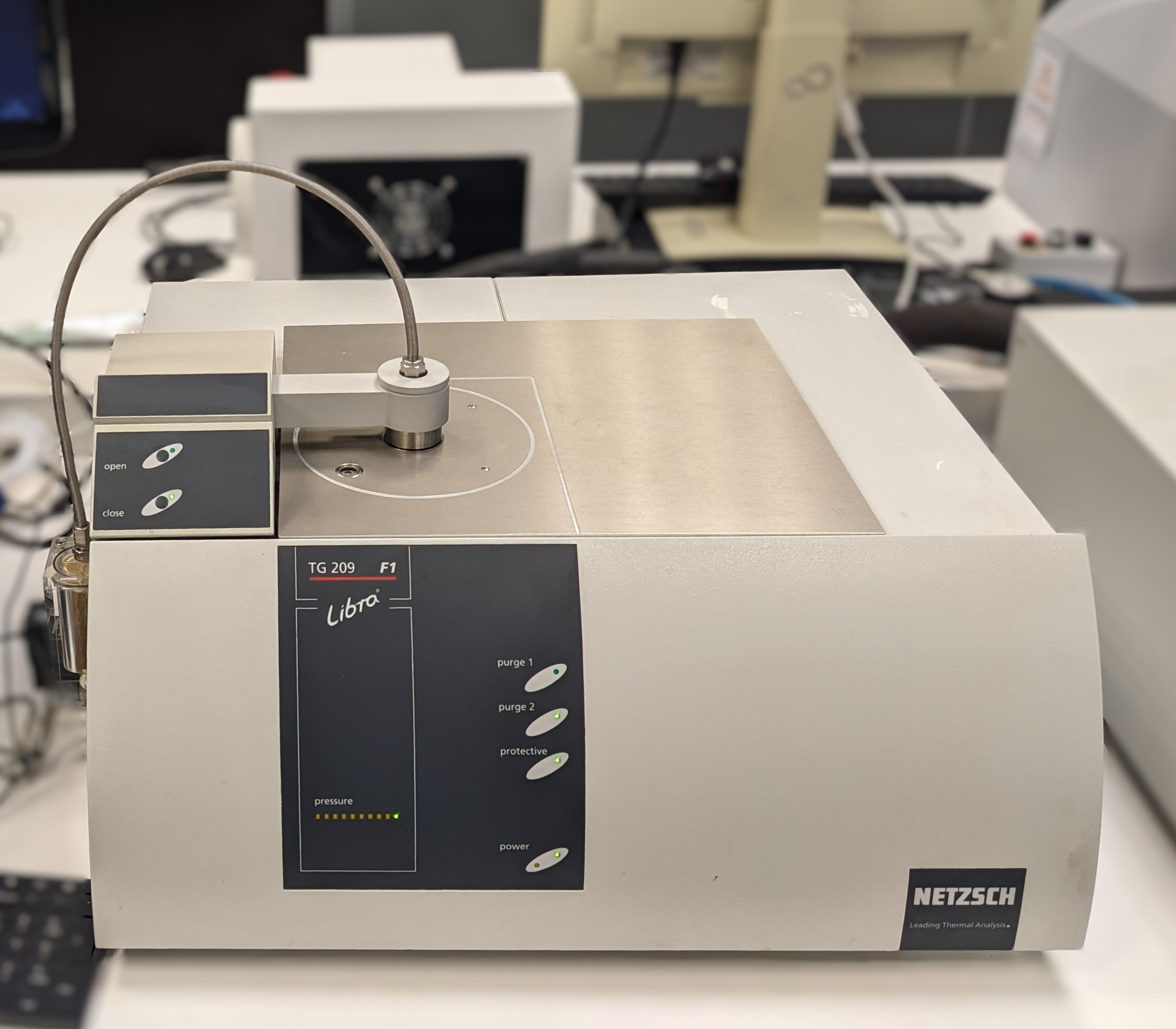

The TGA 209 F1 Libra is an advanced instrument specifically designed to perform

thermogravimetric analysis with high accuracy and reliability. This model stands out

for its wide temperature range, which allows the study of materials in a wide range of

thermal conditions.

The TGA 209 F1 Libra is equipped with a highly sensitive balance that can detect

minute changes in sample mass, ensuring accurate results. The ability of this

equipment to handle samples with different characteristics, including solids, liquids

and powders, makes it a versatile tool for a wide range of applications. In addition,

the TGA 209 F1 Libra allows easy integration with other analytical equipment,

which facilitates complementary studies such as combining it with IR Spectroscopy or a Gas Chromatograph-Mass Chromatograph.

TGA applications

TGA has diverse applications in multiple research fields and industrial sectors. Some of the most relevant applications are presented below.

- Thermal resistance evaluation: TGA is used to determine the thermal stability of materials at high temperatures, which is crucial in the selection of materials for applications involving extreme temperature conditions.

- Characterization of degradation processes: This technique allows the study of how materials decompose when exposed to heat, providing vital information to improve the service life and safety of products such as polymers and composites.

- Determination of oxidation temperatures: TGA can identify the temperatures at which materials begin to oxidize, essential information for the design of oxidation-resistant materials for aerospace and automotive applications.

- Calculation of the different materials that make up the sample: The analysis allows a sample to be broken down into its individual components, such as fillers in plastics, which is essential for quality control and the formulation of new materials.

- Determination of absorbed moisture content: TGA is used to measure the amount of moisture a material has absorbed, which is important in the food and pharmaceutical industry.

- Volatilization rate of materials: The technique helps to determine how fast materials volatilize at different temperatures.

- Thermal cracking point of base fluids: TGA is used to identify the temperatures at which base fluids or formulations begin to thermally decompose, essential for the design of lubricants and other industrial products.

- Combustion and oxidation research: Allows detailed study of combustion and oxidation reactions, useful in the automotive and aerospace industries for the development of fire and heat resistant materials.

- Quality control and assurance: TGA is widely used in quality control to ensure that products meet the required stability and safety standards before being marketed.

These applications underline the flexibility and relevance of TGA in the field of scientific research and industrial development, providing accurate and efficient solutions to a wide range of analytical challenges.

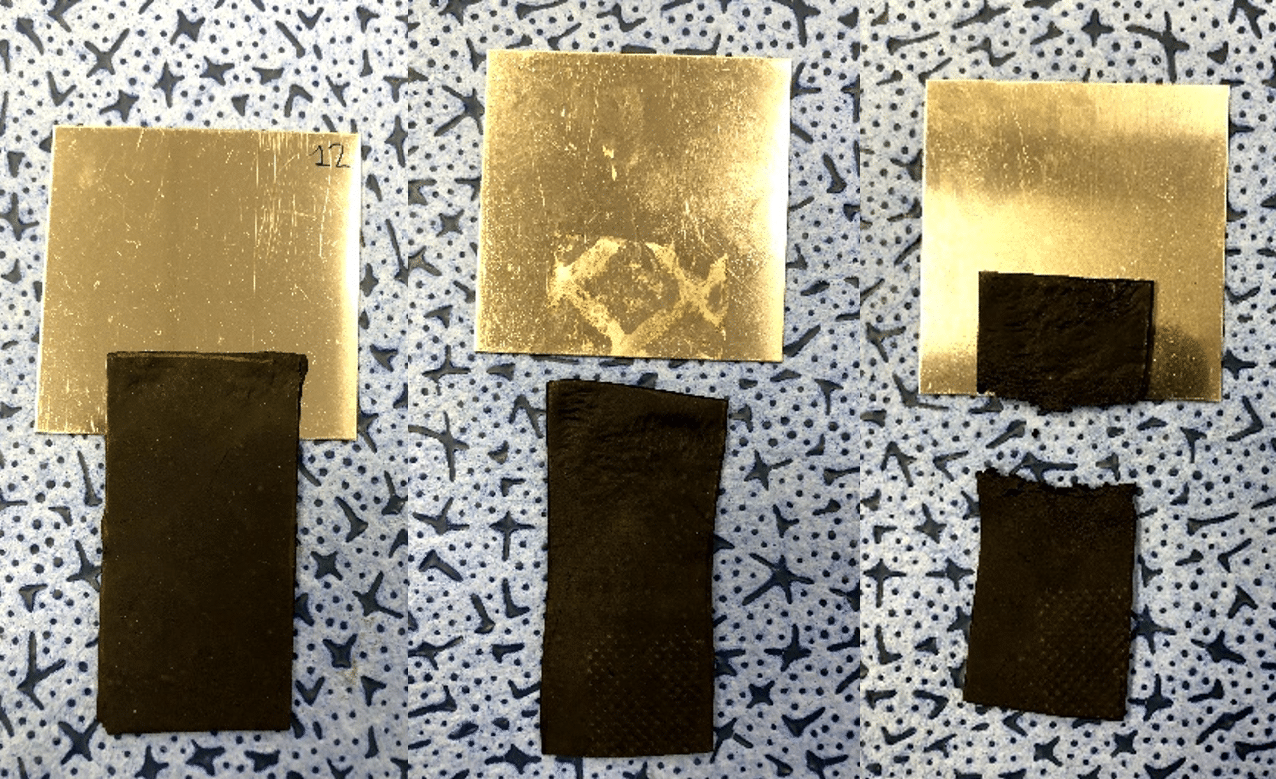

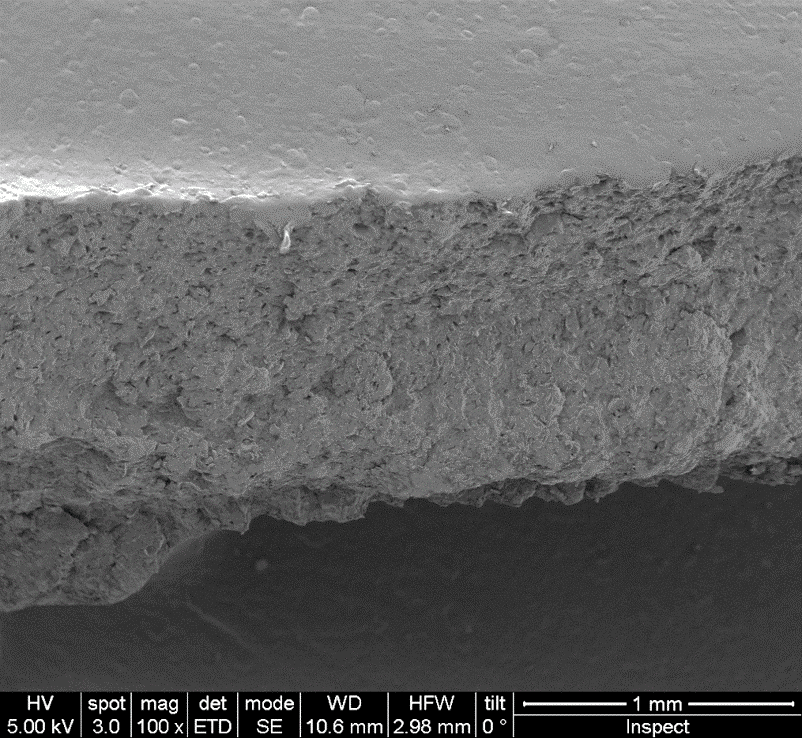

Here are some examples of the use of TGA at INFINITIA:

If you need to apply this equipment in one of your projects, do not

hesitate in contact us. In Infinitia we are here to help you.