What is the thermal shock chamber?

The thermal shock chamber is an essential piece of equipment in product research and development laboratories, designed to simulate sudden temperature changes in materials and components. Its main function is to expose test objects to extreme temperature fluctuations, thus evaluating their resistance and behavior under thermal stress.

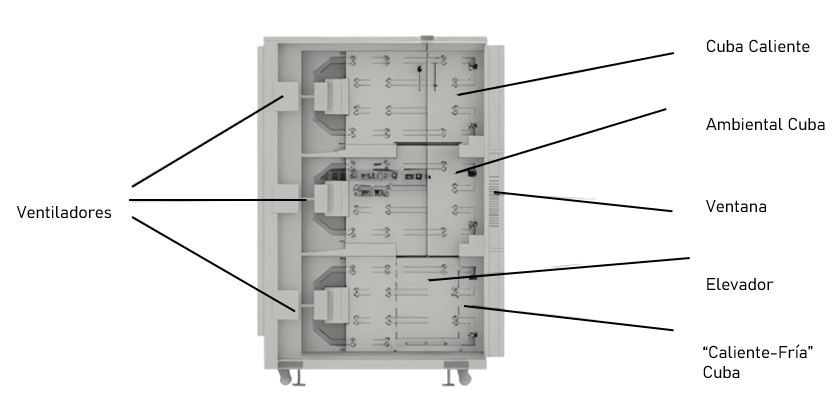

This tool is key to identify how materials react to thermal shocks that occur in real conditions of use, where rapid temperature changes can cause failures or defects in the product. Thermal shock chambers have extreme temperature compartments (hot and cold) that allow the rapid passage of objects between them, generating a thermal shock that accelerates aging or stress processes, allowing life testing and simulating the behavior against external agents.

How does the thermal shock chamber work?

The operation of this equipment is based on the rapid transfer of test objects between high and low temperature environments. Products are subjected to several exposure cycles, allowing identification of whether the material is expanding or contracting too quickly and whether it is showing fractures, color changes or deformations. Tests can be programmed with precise temperature and time parameters, ensuring that tests are tailored to the specific needs of each product or material.

The results obtained from a thermal shock chamber test are interpreted by analyzing the physical and functional changes of the material under study. The steps in conducting a typical test begin with setting the temperature and cycle time parameters, followed by insertion of the material into the chamber. Subsequently, the material is rapidly cycled between the high and low temperature zones, repeating the cycle as programmed. Finally, the materials are evaluated visually and by functional testing to check for damage, cracks or performance failures.

The testing process within a climatic chamber is systematic and highly controlled. First, a cycle program is defined that establishes the environmental conditions to be replicated, as well as the exposure times in each phase. Next, the product or material is placed inside the chamber, ensuring that the sensors are well positioned to monitor changes in temperature and humidity.

After running the test program, the collected data is analyzed to identify how the object has reacted to the simulated conditions. This analysis makes it possible to determine whether the product meets durability standards or is susceptible to failure under certain environmental conditions. Climatic chambers are therefore essential tools in quality control and in the development of products that must be reliable and durable.

Benefits of the climatic chamber

A key benefit of the thermal shock chamber is its ability to perform accelerated temperature cycling failure testing, which allows for a significant reduction in analysis time compared to long-term field testing. These tests are critical for industries such as automotive, electronics and aerospace, where products must be able to withstand abrupt temperature changes during day-to-day use. By simulating these changes in a laboratory, failures can be identified before the product goes to market, helping to improve its reliability and quality.

Thermal shock chamber equipment

The WEISS TS-120 thermal shock chamber model, used by INFINITIA, is an advanced thermal shock chamber designed to perform high precision tests under extreme thermal stress conditions. This equipment stands out for its ability to subject materials and products to rapid temperature changes between hot and cold environments, which makes it possible to simulate real conditions of use where thermal variations can be abrupt. Thanks to its state-of-the-art technology, the WEISS TS-120 offers precise control over thermal shock cycles, making it a crucial tool for evaluating the strength and durability of products under demanding conditions. The ability to program thermal ramps and rapid transitions ensures that both gradual and extreme scenarios can be replicated in a controlled manner.

On a general level, thermal shock chambers such as the WEISS TS-120 are used in a wide variety of industrial sectors, such as automotive, electronics and aerospace, where products must meet strict quality standards. Such equipment is indispensable to ensure that products can not only withstand the actual conditions of use, but also offer long-term reliability and durability under constant thermal stress.

In particular, the WEISS TS-120 has established itself as one of the most advanced and reliable options in its class. This equipment not only enables standard thermal shock testing, but also offers additional features such as rapid transfer between the hot and cold chambers, ensuring that materials do not suffer additional damage during testing. This accuracy is especially useful in sectors such as forensic engineering, where it is critical to replicate the exact conditions under which material or product failures occurred. With the WEISS TS-120, it is possible to identify failures with high accuracy, facilitating improvements in the design and quality of products under analysis.

In summary, the WEISS TS-120 is an advanced thermal shock chamber that offers a combination of accuracy, reliability and adaptability in a wide variety of industrial applications, ensuring that the products tested meet the highest standards of quality, durability and safety.

Equipment applications

The thermal shock chamber has key applications in a variety of industries, enabling the evaluation of how products and materials react to extreme thermal conditions. This versatility makes the equipment indispensable in sectors such as materials research, electronics, automotive and aeronautics. Some of the most important applications are described below:

- Accelerated failure testing: One of the most important applications is accelerated failure testing. Through rapid high and low temperature cycling, it is possible to identify how products will fail during their lifetime, simulating several years of use in just a few hours or days. This is especially useful in the automotive and aerospace industries, where components are subjected to drastic temperature changes in a short period of time.

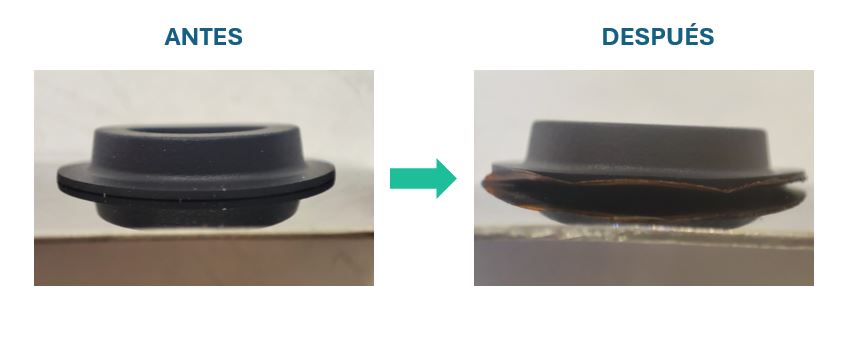

- Verification of coatings and paints: In sectors such as automotive or household appliances, it is essential to evaluate the resistance of coatings and paints applied to products. Thermal shock chambers make it possible to simulate the conditions to which these coatings will be exposed, verifying whether they crack, peel or change color under extreme temperatures. This type of testing ensures that products maintain their appearance and durability even under adverse conditions.

- Characterization of ceramic materials: Ceramic materials, known for their high temperature resistance, must also be evaluated under extreme thermal shock conditions. This equipment allows the thermal characterization of ceramics, determining their ability to withstand rapid temperature changes without fracturing or suffering structural damage. This application is critical in the materials industry, where ceramics are used in a variety of products that must withstand high levels of thermal stress.

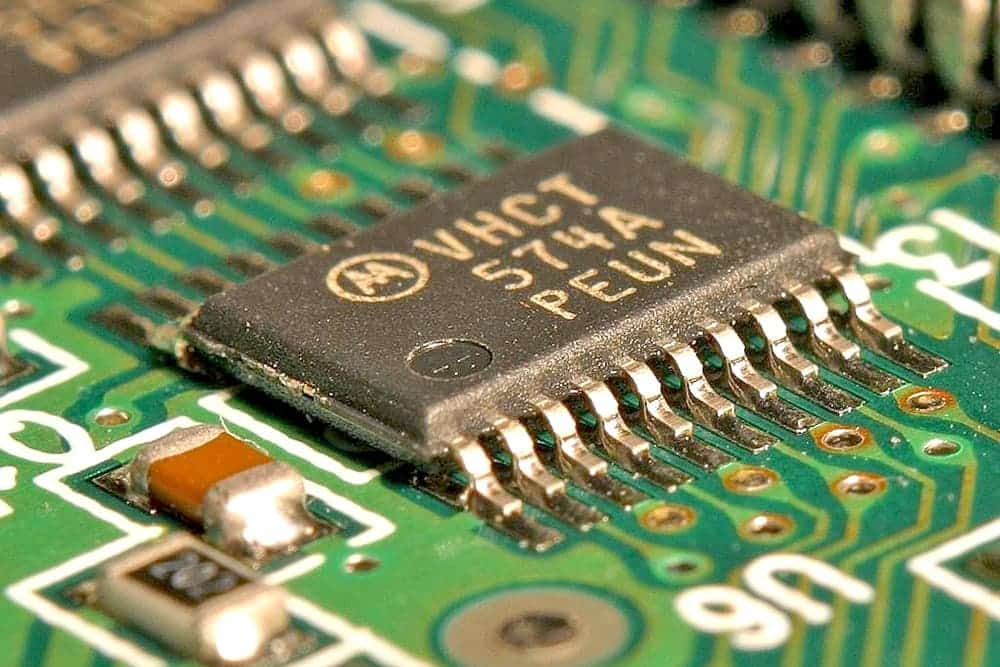

- Electronic component testing: In the electronics industry, components are often subjected to thermal shock tests to ensure that they can function properly even in environments with extreme temperature changes. Thermal shock chambers are used to verify the resistance of circuits, semiconductors and other electronic components that must perform optimally under demanding conditions.

Aerospace testing: The aerospace industry also benefits greatly from this type of equipment. Materials and components used in aircraft and satellites are constantly exposed to extreme temperature variations during flight. Thermal shock chambers make it possible to simulate these conditions in a controlled environment, ensuring that materials are able to withstand them without failure.

In summary, the thermal shock chamber is an indispensable piece of equipment in the evaluation of products and materials that will be exposed to rapid and extreme temperature changes. Its ability to perform accelerated tests, together with its precision in the control of thermal cycles, make it a key tool in the development of more durable and safer products.

The WEISS TS-120 thermal shock chamber model used by INFINITIA offers advanced solutions for a variety of industrial applications, ensuring that products meet the highest standards of quality and reliability.

Te mostramos algunos ejemplos del uso de la Cámara Climática INFINITIA:

Here are some examples of INFINITIA’s use of the crash chamber: