What is the Universal Testing Machine?

The universal testing machine is an equipment designed to measure the mechanical properties of different materials through tensile, compression, bending and shear tests.

This equipment is widely used in quality control and research laboratories, as well as in the field of failure analysis and forensic engineering, to analyse how materials respond to different types of mechanical stress.

Thanks to its versatility, the universal testing machine enables accurate testing of a wide range of materials, from metals and plastics to textiles, providing key data on their strength, elasticity and durability. Its robust, modular design makes it an essential tool for ensuring the quality and performance of products in industrial sectors and in materials testing.

How does the Universal Testing Machine work?

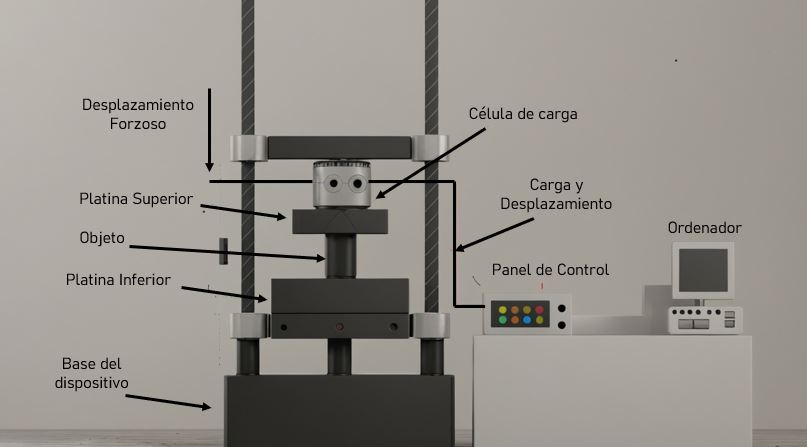

The operation of the universal testing machine is based on the controlled application of force through a motorised system which generates the movement necessary to perform the test. The specimen is placed in specific grips or clamping devices appropriate to the type of test to be performed.

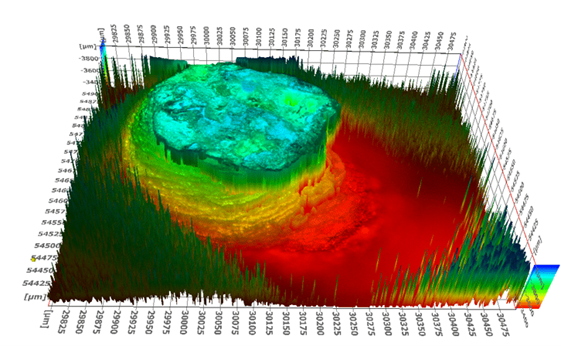

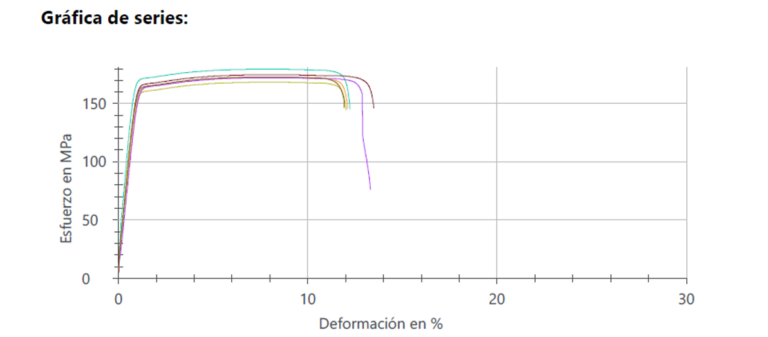

During the test, sensors integrated in the machine record real-time data, such as the applied force and the deformation of the specimen. This data is processed and graphically represented, allowing the results to be accurately interpreted and the mechanical properties of the material under test to be assessed.

The interpretation of the results obtained with this equipment is a process that combines the observation of the generated graphs, generally stress-strain curves, with the analysis of quantitative values such as yield strength, maximum strength and modulus of elasticity.

To perform the test, basic steps are followed: prepare the sample with the required dimensions, place it correctly in the machine, select the appropriate programme according to the type of material and test, and finally run the test. The integrated software facilitates the analysis and export of the results, allowing precise and detailed documentation, ideal for scientific research and quality control reports.

Benefits of the Universal Testing Machine

One of the most outstanding benefits of the universal testing machine is its versatility to adapt to different types of materials and tests, making it an indispensable tool for a wide range of industries. Its ability to measure mechanical properties with high accuracy ensures that products meet the highest quality standards, improving product reliability and safety. In addition, its modular design allows the instrument to be customised with specific accessories for specialised tests, maximising its usefulness in the laboratory.

Universal Testing Machine Equipment

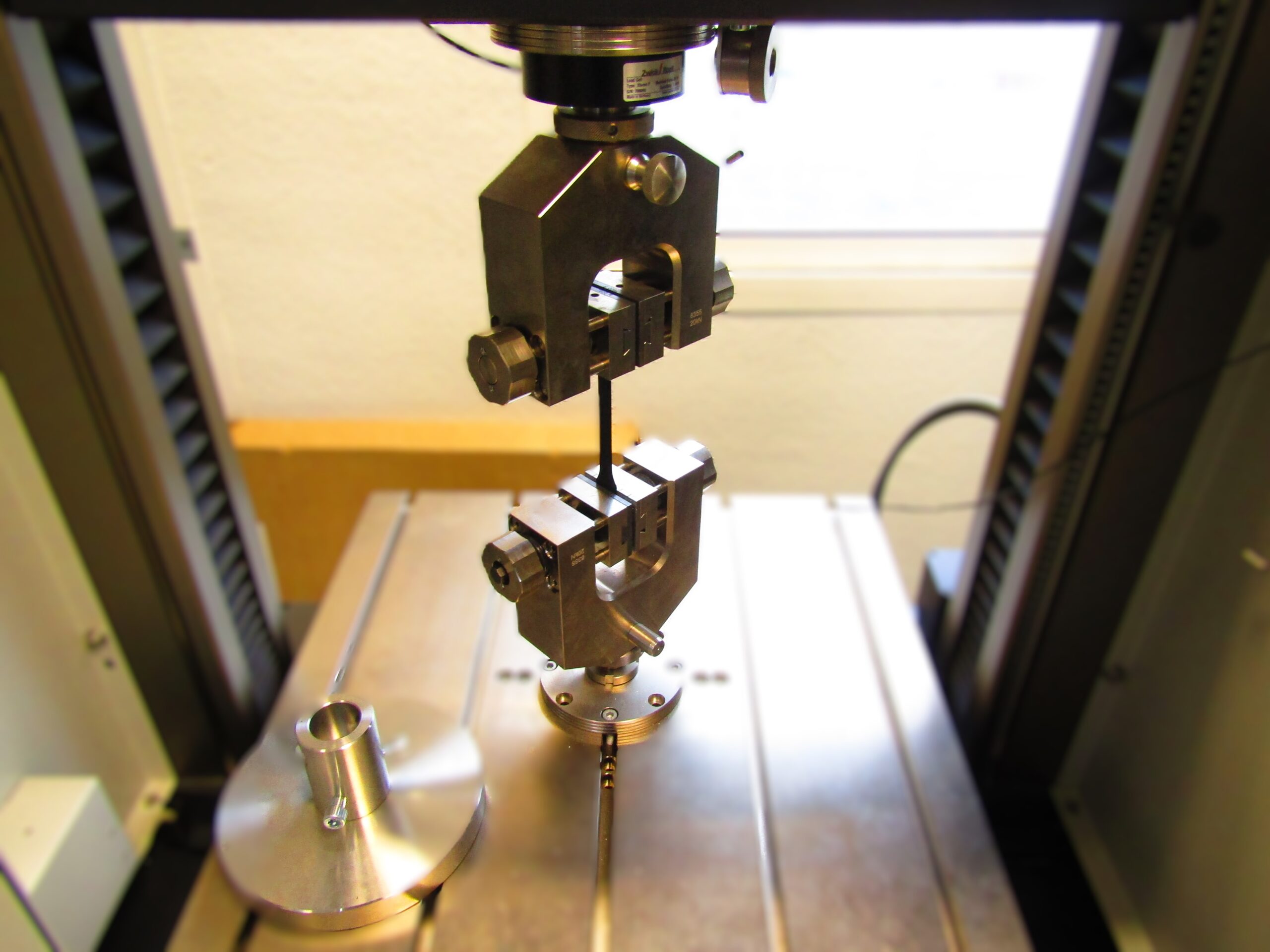

INFINITIA has the ZwickRoell Allround4nezozc, a universal testing machine designed to perform advanced mechanical tests with precision and efficiency. This machine stands out for its adjustable load capacity, which reaches up to 250 kN, allowing testing of metals and alloys in a wide variety of materials, from light textiles to high-strength metals.

Its control system includes high-resolution sensors to ensure measurement accuracy, while its integrated software facilitates test programming and analysis. In addition, the Allround4nezozc’s robust design ensures reliable performance under heavy use, making it an essential tool for ensuring the quality and durability of materials in sectors such as construction, automotive and aerospace.

Equipment applications

The universal testing machine has a wide range of applications in various industrial and research sectors, allowing the testing of metals and alloys, as well as other materials of different natures. Some of the most relevant applications are described below:

- Metal testing: The machine is used to assess the strength and ductility of metals, ensuring that they meet the specifications required in industries such as automotive, aerospace and construction. These tests allow key properties such as yield strength, tensile strength and maximum elongation before fracture to be determined.

- Textile testing: In the textile industry, this equipment is used to analyse the tensile strength, elasticity and durability of fabrics. These tests are essential for developing high quality products in clothing, upholstery and technical materials used in sectors such as sports and medical.

- Plastics analysis: Plastics are subjected to tensile, compression and flexural tests to determine their durability and behaviour under different loading conditions. These tests are essential in the production of packaging, or to approve a polymer laser welding process.

- Rubber evaluation: In the rubber industry, this equipment is essential for analysing the elasticity, tensile strength and deformation of products. This is crucial to ensure the performance of materials used in tyres, seals and other components. For example, after undergoing an accelerated ultraviolet light ageing test.

- Tests on paperboard and paper: Tests for compressive and tensile strength are essential to ensure that packaging materials and other paper products meet quality and durability requirements.

- Concrete testing: In the construction industry, this equipment is used to measure the compressive and flexural strength of concrete, ensuring its reliability and compliance with safety regulations. These tests are essential to ensure the structural stability of buildings, bridges and other infrastructure.

- Testing in the aerospace industry: The universal testing machine plays a crucial role in the evaluation of materials used in the manufacture of aircraft and space components. These tests ensure that materials meet the exacting quality and safety standards required in this sector.

- Automotive analysis: In the automotive sector, this equipment is used to assess the strength and durability of materials and components, from metal parts to plastics and textiles used in vehicle interiors. These tests contribute to improving the safety and performance of automobiles.

In conclusion, the universal testing machine is an indispensable tool for the mechanical characterisation of materials in a wide variety of industrial and scientific sectors. Its ability to perform accurate tests and adapt to different experimental needs makes it a versatile and reliable piece of equipment.

At INFINITIA, this equipment is used to guarantee the quality of materials and products, contributing to the development of innovative solutions that meet the most demanding standards, to the development of safe and quality products.

Here are some examples of the use of the universal testing machine at INFINITIA: