Did you know that one of the types of electronic component testing we perform at Infinitia is IP testing? Indeed, a concept widely used in the industry, as it allows to measure the degree of tightness of these components against solids or liquids.

Here we explain what IP protection is, its importance and the different degrees that exist.

IP protection: definition

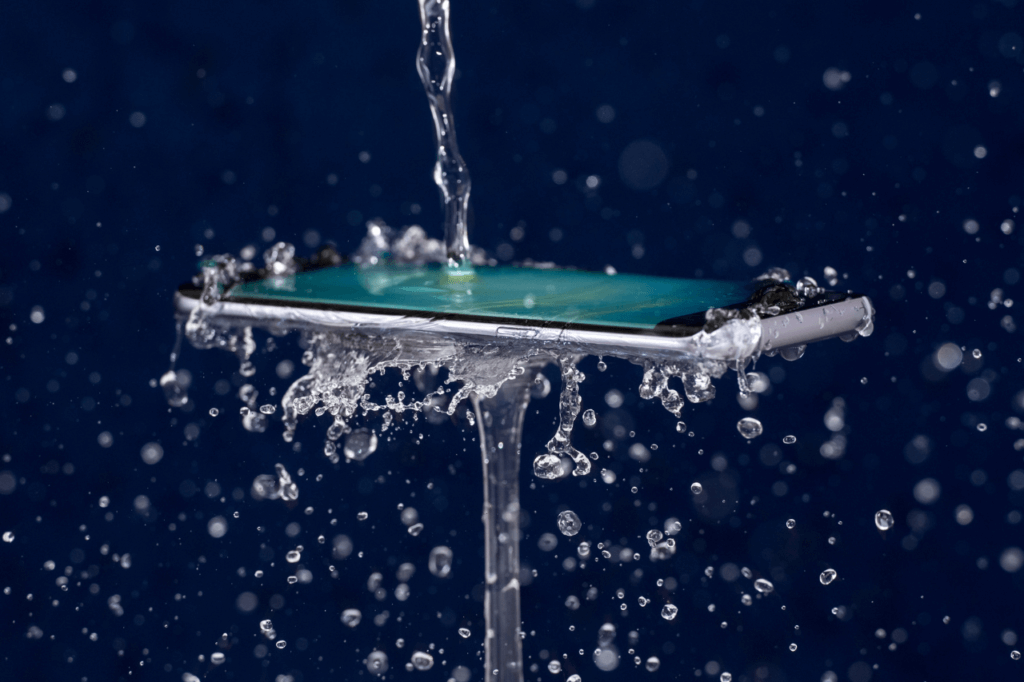

IP protection (Ingress Protection) is a system for classifying components according to different degrees of protection against solids and liquids. The purpose of IP protection is none other than to create products, in this case electrical and electronic products, in complete safety and in compliance with quality standards and regulations.

Thus, the IP degree of protection comes from the hand of 2 digits. The first digit ranges from 0 to 6 and indicates the degree of IP protection against solids such as dust particles. It should be noted that the higher the number, the higher the level of protection. Thus 0 is synonymous with no protection and 6 with complete protection.

For its part, the second digit, corresponding to liquids such as water or even the humidity of that water, is a scale that can go from 0 to 9. Again, 0 is equivalent to no protection, while 9 is equivalent to full protection.

The importance of IP protection in electronics and electricity

IP protection is key to ensuring the quality of electronic and electrical parts. In other words, it has a direct impact on properties such as performance and resistance, durability, correct operation and, of course, the safety of the users who will be using these products.

In addition, it should be noted that it is an international standard. Thus, it provides valuable information not only between manufacturers and suppliers, but also with the end consumer. It is a universal industry standard. Thus, in case of communication problems, it is a recognizable character.

The different degrees of IP protection most commonly used in electronics

As mentioned above, there are different IP ratings. Depending on the number we find on the left or on the right, we can check if they are more or less restrictive in the protection of solids and liquids.

Here are some examples of the most commonly used IP ratings in the electronics industry:

IP20

This IP protection allows the electronic part to be protected against solids larger than 12 mm (dust), but there is no protection against liquids such as water.

IP44

This IP44 allows to protect the electronic components from solids larger than 1 millimeter and from water splashes.

IP54

This is a highly demanded IP degree of protection for electrical and electronic products. The components are protected against the entry of dust, preventing it from affecting the operation of the part. It is also protected from water splashes.

IP65

In this case, total protection is given in solids. Specifically, in dust particles. Likewise, an electronic component with an IP protection of this type is protected from water jets.

IP66

It is similar to IP65, but with a higher water pressure and therefore a more demanding test.

IP67

Again, there is complete protection against dust and, this time, the electrical part can be temporarily submerged in water up to 1 meter deep.

IP68

This IP protection provides complete protection against dust and, in this case, it can be permanently immersed under water. This is why it is usually used in electrical or electronic devices, used under the sea as a diving flashlight.

At Infinitia, we are specialists in IP protection testing.

In Infinitia’s industrial engineering laboratory, we are experts in measuring the different degrees of IP protection of electronic components. This is a guarantee for our customers that they are manufacturing efficient parts and that, later on, they will be part of quality electrical and electronic products.

In Infinitia we have all the human and material equipment necessary for a quality engineering work. Find out more and do not hesitate to contact us.