What was the challenge or problem to solve?

This was a particularly complex job, in which the INFINITIA team had to demonstrate its versatility and ability to adapt to the client’s requirements, taking advantage of the benefits offered by the manufacture of prototypes using 3D printing.

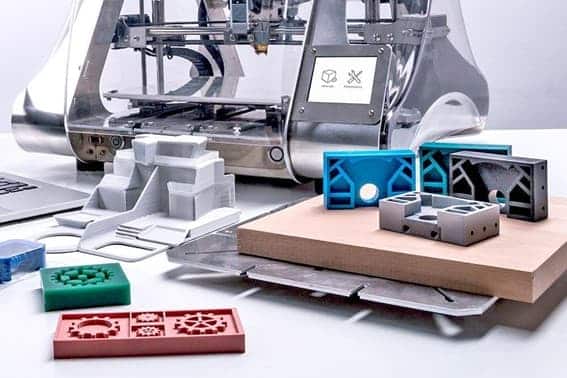

Given all these requirements, INFINITIA’s proposal for the development of the project was to make prototypes of the parts using 3D printing and test them with the engraving robot in situ, at the customer’s facilities. This approach was associated with significant difficulties in addition to the tight deadlines mentioned above, including the large size of the parts, which also had a complex geometry that had to be replicated as accurately as possible in the prototypes to ensure their resemblance to the real parts.

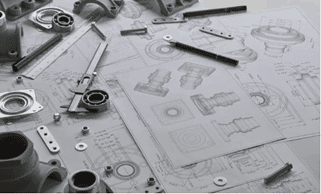

Due to the need to take a large number of factors into account when preparing parts for 3D printing, INFINITIA’s Product Development Department employed powerful professional CAD software capable of carrying out complex design processes.

We proceeded to manufacture the prototypes to simulate the parts to be laser engraved, using a 3D printer with FDM technology. This tool is particularly interesting due to its capacity to produce large parts, as well as the speed and precision it has already demonstrated in previous projects and work.

Different verification and metrology methods were then applied to ensure that the geometry of the prototypes was as accurate as possible. This step was particularly important as dimensional verification ensures that the geometry of the manufactured object corresponds to the digital model.

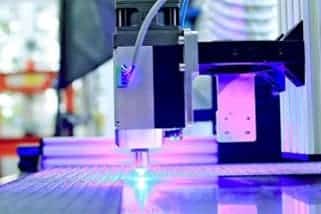

The work was completed by carrying out the rest of the tasks directly at our customer’s premises together with those in charge of programming the laser engraving robot in order to optimise the process. This direct contact with the client was essential and allowed us to speed up the process, as we knew first-hand the different needs, requirements and factors involved in the project.

Thanks to the work carried out and the excellent finish of the prototypes manufactured by INFINITIA, the client was able to prepare all the programmes and test them before receiving the real parts, ensuring the optimum engraving result beforehand and thus meeting the required deadlines.