What was the challenge or problem to be solved?

The INFINITIA team was commissioned to carry out reverse engineering and investigate a critical problem in the air filters of a client in the industrial sector.

The company had detected emissions that exceeded regulatory limits, which jeopardised both its legal compliance and the sustainability of its operations. Initially, the client suspected that the air filters were becoming prematurely saturated due to the presence of metallic particles, although the true cause of the failure was unclear.

However, the main challenge was not only to analyse the obvious contaminants, but also to identify adsorbed components in the air filters, especially those in the gaseous phase that could go unnoticed in traditional analyses.

The complexity increased due to the volatilisation of certain substances during the preparation of the samples, which required a meticulous approach and advanced analysis techniques. In addition, the limited amount of sample available required rigorous planning to maximise the information obtained.

How was it addressed or what was the solution?

INFINITIA designed a comprehensive approach to address this challenge, combining advanced methodologies and meticulous analysis:

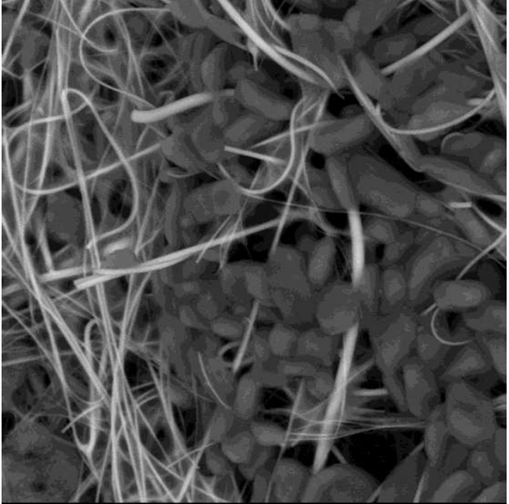

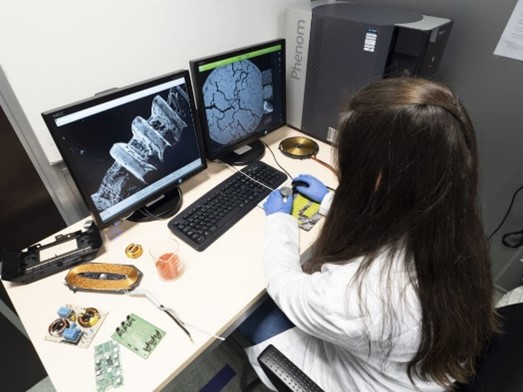

- Preliminary filter analysis: An initial inspection was carried out to identify obvious contaminants using scanning electron microscopy (SEM) and energy dispersive spectrometry (EDX) analysis. This allowed for an initial characterisation of the solid particles adhering to the filter.

- Detection of gas-phase compounds: To address the volatile and adsorbed contaminants, advanced techniques such as thermodesorption coupled with gas chromatography and mass spectrometry (TD-GC-MS) were applied. This approach made it possible to detect compounds that had been adsorbed on the air filters and were not visible in the initial analysis.

- Identification of the critical contaminant: Through exhaustive analysis, the main contaminant responsible for the premature saturation of the filter was determined. This compound had not been previously considered in the filter requirements, and therefore caused the filtration failure.

- Review of operating conditions: Based on the results, we worked together with the client to identify and adjust the system parameters to minimise the failure.

The project was a success in identifying and solving a complex problem that compromised the air filtration system. Thanks to the combination of advanced analysis techniques and a root cause-oriented approach, INFINITIA enabled the client to resolve the out-of-standard emissions and adjust their processes to avoid future saturation of the air filters.

This case not only highlights INFINITIA’s ability to address critical industrial problems, but also demonstrates its commitment to delivering practical and scientifically sound solutions, helping its clients maintain regulatory compliance and operational efficiency.