What was the challenge or problem to be solved?

The main challenge of the project developed by INFINITIA’s Forensic Engineering team was the analysis of alloys to identify the most suitable material. These alloys were used by different competitors in the same industrial application. Choosing the right material for a specific application is key to ensure the efficiency, durability and performance of any product, so reverse engineering analysis is a fundamental tool to make an informed decision.

Our client wanted to compare materials used by competitors in order to identify which one offered the best performance and best suited their needs. The challenge was to accurately analyse and quantify the elements present in each alloy to determine which offered the best performance. The goal: to perform a detailed analysis of the compositions and select the most advantageous option.

How was it approached or what was the solution?

To achieve the objective, a structured approach was followed, starting with a comprehensive literature search. Through professional databases and specialised libraries, the team collected key information on alloys used in similar applications. This step was essential to establish a solid basis for comparison and to define which materials should be further analysed.

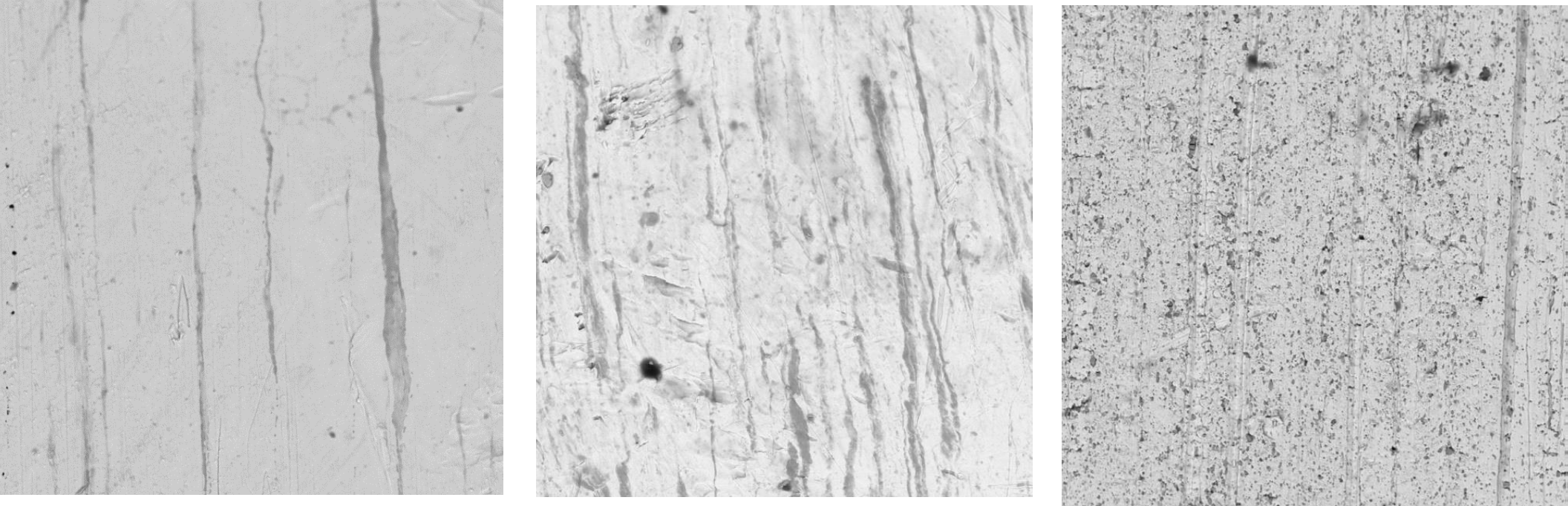

Once the samples of interest were selected, a detailed visual inspection was carried out using a scanning electron microscope (SEM). This technique allowed the team to examine the morphology and structure of the alloys at the microscopic level, identifying variations that could affect their performance in the final application. Surface morphology is a critical aspect, as it directly influences the behaviour of the material under real conditions of use.

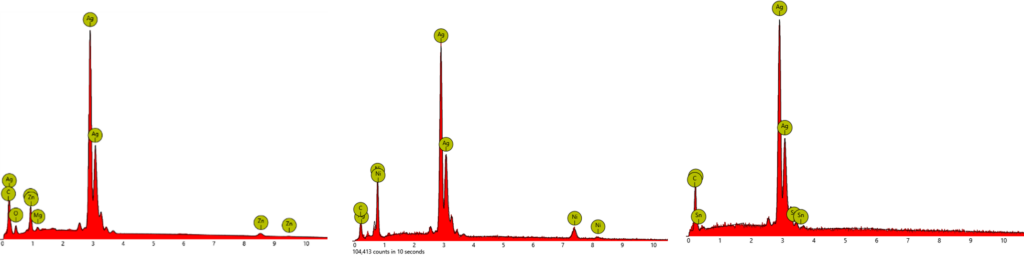

Subsequently, a compositional analysis was carried out using an X-ray detector (EDX), which allowed the elements present in each alloy to be identified and quantified semi-quantitatively. With this information, the team was able to make a detailed comparison between the different options. Thanks to this comprehensive approach, INFINITIA was not only able to identify the materials used by competitors, but also to determine which offered the best performance for the customer’s application.

The project was a success, as it provided a clear and informed recommendation, allowing the client to select the most suitable material for their product.