What was the challenge or problem to be solved?

When it comes to the aluminium anodising process, maintaining the aesthetic and functional integrity of the coatings is crucial to ensure the quality and durability of the final product. Recently, at INFINITIA, we were faced with this challenge when our customer noticed that the anodised surface of some of their parts was flaking and failing after standard cleaning procedures. This problem not only compromised the appearance of the product, but also raised serious questions about the quality of the existing manufacturing process.

The main objective of this project was to identify why the coating was peeling off during cleaning and to develop a solution that would prevent such failures in the future. INFINITIA’s forensic engineering team set about studying the problem in depth, with the goal of not only finding the root cause of the failure, but also implementing improvements that would ensure quality and customer satisfaction.

How was it addressed or what was the solution?

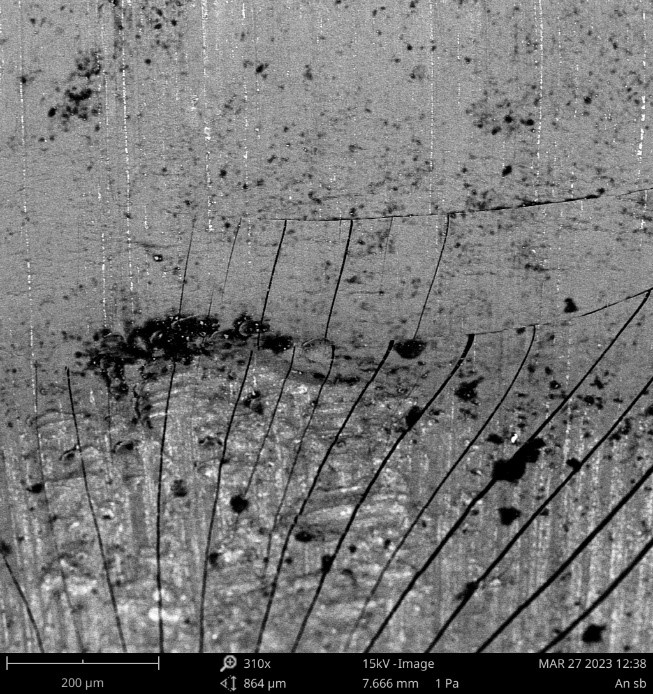

The first step in our investigation was to perform a thorough visual analysis of the affected parts compared to new parts, using professional cameras and optical microscopes. This initial examination allowed us to identify the most compromised areas and establish preliminary hypotheses about the causes of the damage.

Subsequently, new parts were cleaned with various application-specific products to observe how the coatings reacted. This method was essential to rule out or confirm whether the cleaning agents contributed to the problem.

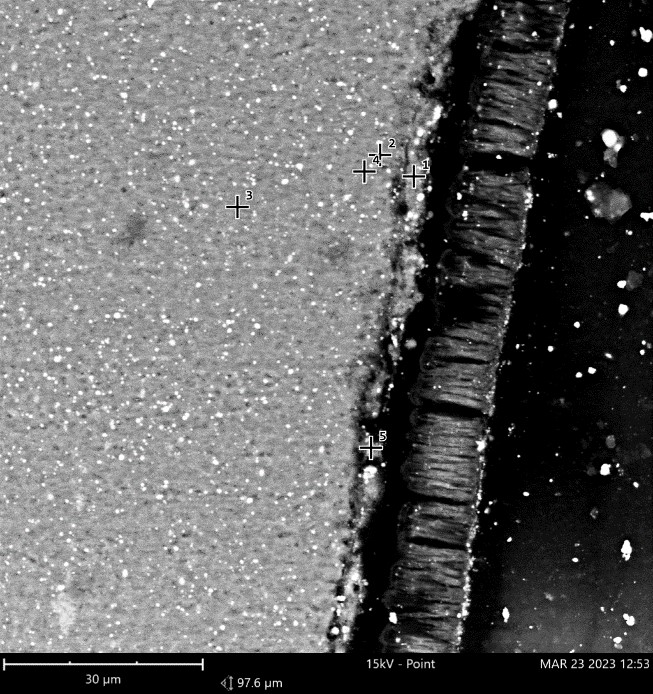

Finally, a scanning electron microscope (SEM) was used to obtain detailed images of the microstructure of the parts. This in-depth analysis revealed specific deficiencies in the anodising process that triggered the failure in contact with certain cleaning chemicals. With these results, adjustments to the anodising process and post-treatment of the parts were proposed.

These changes not only solved the problem of coating peeling, but also improved the overall strength of the treated surface, thus ensuring a more durable and aesthetically appealing product. This significant improvement in the manufacturing process not only met the customer’s quality standards, but also reinforced its reputation for quality in the anodised aluminium industry.