What was the challenge or problem to solve?

To identify the cause of the failure, a forensic study was carried out with pieces from different lots, performing various tests in the laboratory.

How was it addressed or what was the solution?

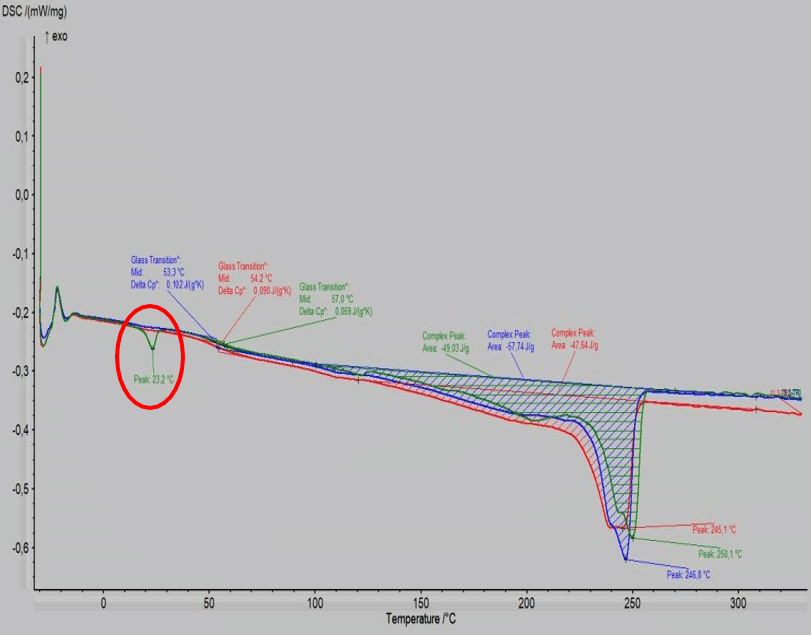

To find the cause of the breakage of the pieces, the material was characterized with infrared spectroscopy (FTIR) and differential scanning calorimetry (DSC) tests.

With the results of the tests, it was detected that in the parts that were broken an essential additive was missing to resist the stresses of the assembly. Taking this into account, it was hypothesized that the raw material used for the production of the batch was not adequate.

Challenge

- Find the cause of breakage of PA66 plastic parts on the assembly line

- Propose a solution to prevent another batch from experiencing the same failure

Solution

- Investigate the material using forensic engineering techniques

- Check with a quick DSC test if the production material of the parts is adequate