What was the challenge or problem to solve?

In this project, the Product Development team was commissioned to study the mechanical and aesthetic characteristics of rubber after being exposed to degradation by ultraviolet light (UV-C). This exposure was intended to simulate an accelerated aging process that would allow observing possible changes in the properties of this material and thus validate whether they met the requirements of the final application.

After exposing the rubbers to ultraviolet light for 7 consecutive days, several mechanical tests were performed to check hardness, elasticity and color variation. In this way, our team found that the color and hardness parameters did not show significant changes. On the other hand, after oxidation with light, a reduction in the ductility of the rubbers was observed and, therefore, an increase in their brittleness.

First, the rubber bands and UV light lamps were placed in the climatic chamber. This type of chamber makes it possible to maintain stable light, temperature and humidity conditions, which are essential for this test. For one week, the rubber was subjected to a simulation of oxidation produced by ultraviolet light.

During this time, documentation and a literature search were carried out. The objective was to choose the most suitable techniques that would allow us to know with certainty the characteristics of the rubbers after the aging process.

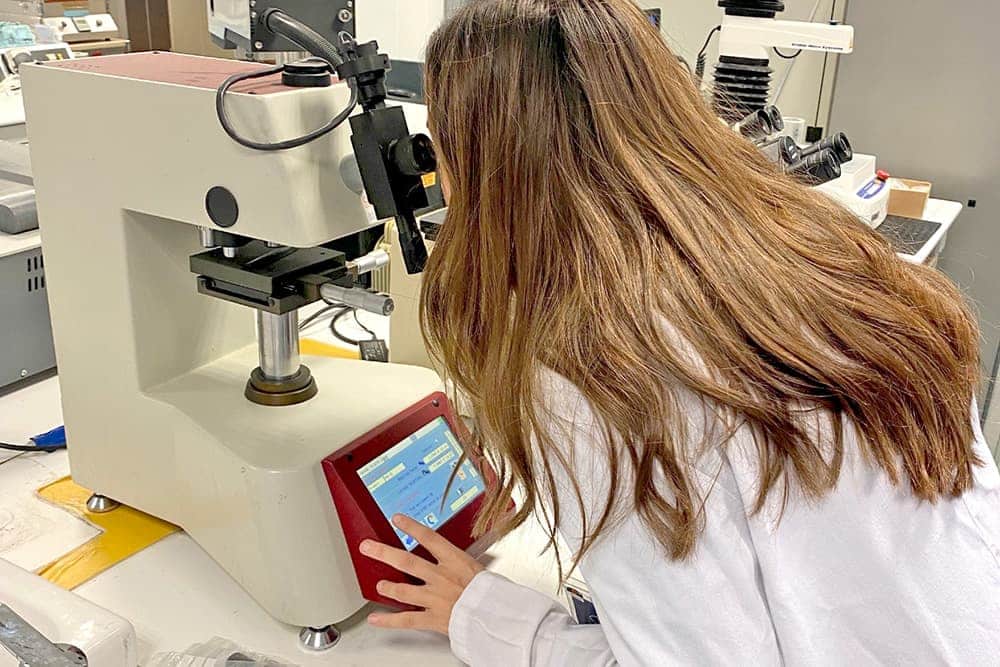

Once the week had elapsed, ductility tests were carried out on the Universal Testing Machine to check whether, after oxidation, the elasticity of the rubbers had decreased. Hardness tests were also carried out with the hardness tester to check the variation of this property in the materials. Finally, color tests were carried out, using a colorimeter to study possible aesthetic changes.

After collecting and analyzing the results, our team proceeded to the final comparative study of the original and oxidized samples. The conclusion was that the aging of the materials had resulted in a loss of ductility and, therefore, an increase in the brittleness of the rubbers.