What was the challenge or problem to solve?

A client wanted to carry out the analysis of detergents to know the effective composition of some batches manufactured by different suppliers. This case of Forensic Engineering was driven by the need to ensure the quality and effectiveness of the detergent in real conditions of use, considering variables such as temperature, type of stain, water hardness and interaction with materials.

The materials team took the initiative to design a meticulous experimental approach. It started with the design of an experimental mode of testing, using samples made from the materials encountered in operating conditions, as well as standardized stains according to regulations. The real conditions of use had to be simulated, maximizing the effectiveness of stain removal and component protection.

The next phase involved mounting samples in an adapted sample holder. Using standard manufactured stains deposited on different materials, the experiment was carried out on a prototype designed to simulate real operating conditions.

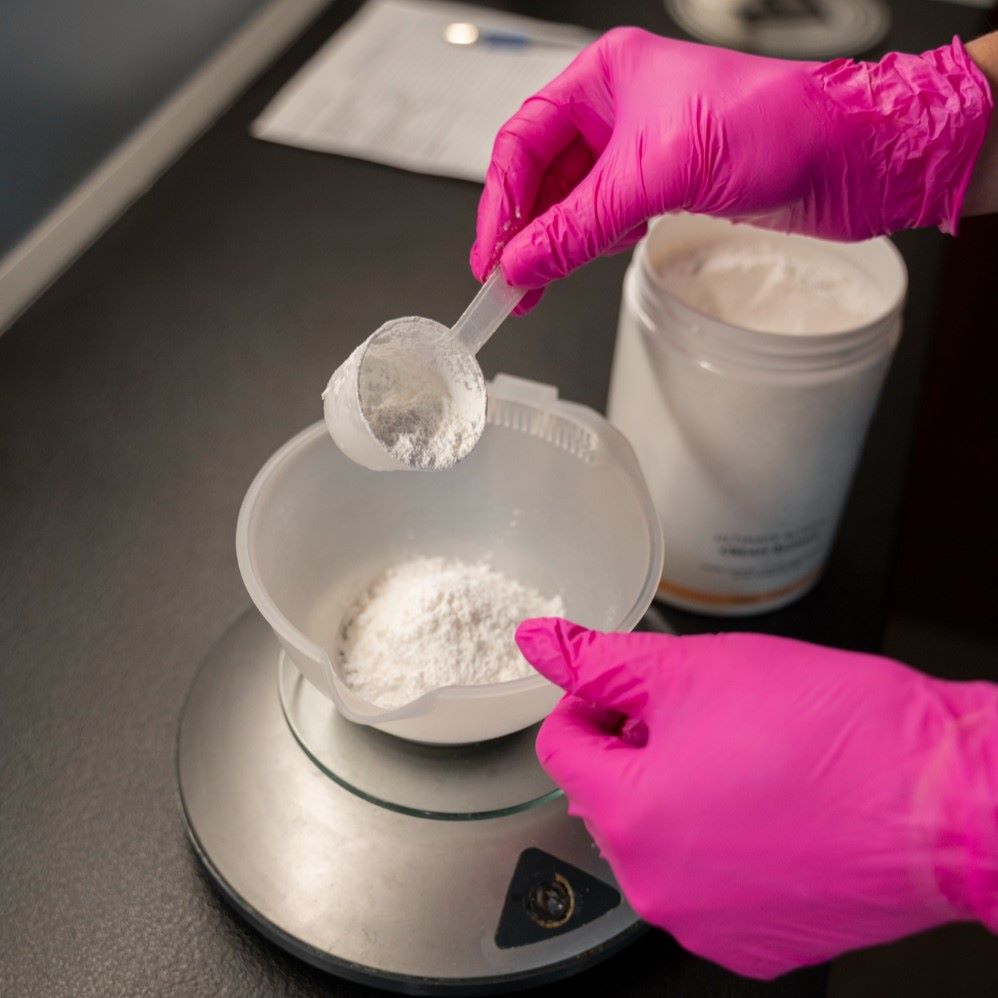

To ensure accurate results, behavioural testing and effectiveness measurements were performed. Scales and visual photographic control were used before and after the washes. This stage was crucial to establish a reliable and repeatable methodology to evaluate the effectiveness of the detergents.

Finally, the evaluation and interpretation of weekly results was essential to provide the client with a clear and reliable picture of the detergents’ effectiveness. This rigorous analysis allowed verification of each supplier’s performance, highlighting those that consistently demonstrated superiority in their formulations.

This comprehensive and detailed approach was the key to the success of the project, identifying the most effective and appropriate detergent for our client’s needs, as well as establishing new internal standards for evaluating future suppliers.