What was the challenge or problem to solve?

The client wanted to know if the mechanical properties of polycarbonate parts that had changed since their installation due to exposure to adverse environmental conditions.

To check if the parts had suffered from aging, it was decided to analyse new parts and parts that had been subjected to use, in order to compare their behaviour and assess the different qualities of suppliers.

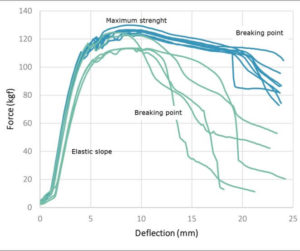

To analyse the samples, the Forensic Engineering team carried out a three-point flexure test. In this test, the bending force and buckling values of the part are recorded.

In this way, the mechanical properties of parts that had been in use could be measured and compared with the properties of new parts.

In the laboratory it was observed that all the used samples showed less plastic deformation before breakage than the new samples, in addition the maximum force supported by the used parts was lower than the new parts and the buckling supported before breakage had been reduced by almost half.

Therefore, it was concluded that the material properties of the parts exposed to the environment had changed compared to the initial ones.

Challenge

- Evaluate the properties of polycarbonate parts subjected to aging in use.

- Compare different grades from different suppliers.

Solution

- Carry out a comparative study of mechanical properties.

- Define a control test to evaluate different qualities and decide whether to discard/accept suppliers’ components.