What was the challenge or problem to solve?

A client needed to carry out the characterization of composite materials to determine the presence of microcapsules in one of their products. This would help optimize certain production parameters and achieve the desired finish in the final product.

The difficulty lay in identifying microcapsules of approximately 3 microns in size, a challenging task due to the variability in the nature, size, and distribution of these microcapsules.

This presented a challenge in interpreting microscopic images, as precision was required.

The success of the project was due to the ability to identify these microcapsules in the samples, revealing differences in the shape, size, and composition of the particles between the samples, thus providing the necessary insights to improve the client’s products.

To address the study, the process began with the receipt of samples sent by the client. A meticulous analysis plan was then developed in consultation with experts in electron microscopy to establish a clear approach.

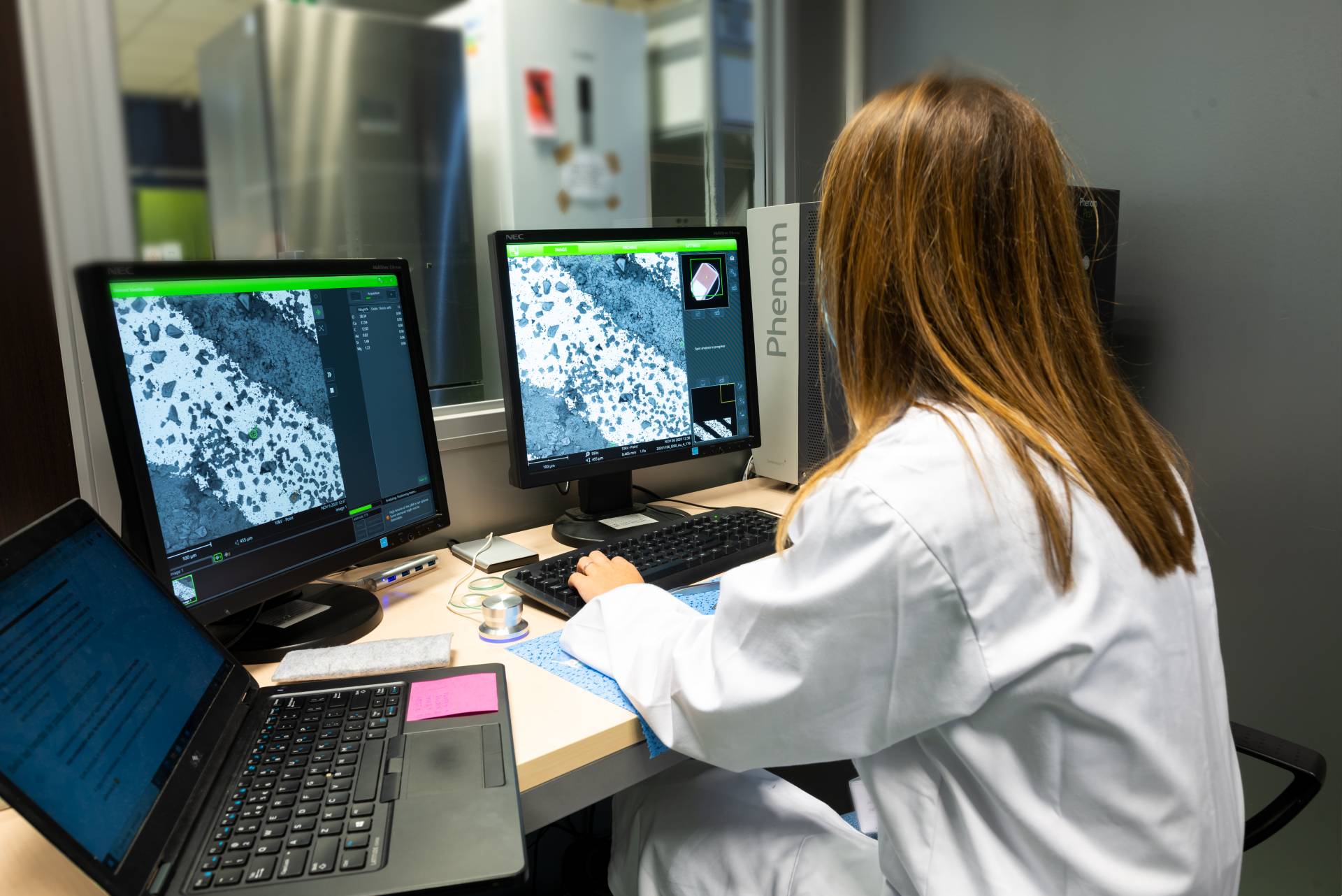

The next step was the preparation of the samples, using specialized equipment to ensure their integrity and viability for microscopic observation. Using a high-resolution scanning electron microscope, specific areas of each sample were analyzed, capturing detailed images that allowed for an accurate evaluation of the present microcapsules.

The processing and analysis of these images were performed with specialized software, enabling the determination of the shape, size, and distribution of the particles. Additionally, their chemical composition was analyzed using energy-dispersive X-ray spectroscopy coupled with the SEM to provide a deeper understanding of the nature of the particles and assess how their composition might have varied based on production parameters.

The detailed results collected for each sample allowed the client to gain a better understanding of the implications of certain factory processes, how they affected the properties of the final product, and thus achieve greater efficiency in production processes.