What was the challenge or problem to solve?

An elegant and transparent glass surface on which scratches or scratches appear easily not only loses aesthetic value, but these defects can affect its functionality, safety of use and have an economic impact due to market claims and loss of quality perception.

How was it addressed or what was the solution?

Before starting to work directly in the laboratories, the materials innovation team carried out a bibliographic study in order to detect patents and the latest existing commercial solutions of coatings with optimum properties for this application.

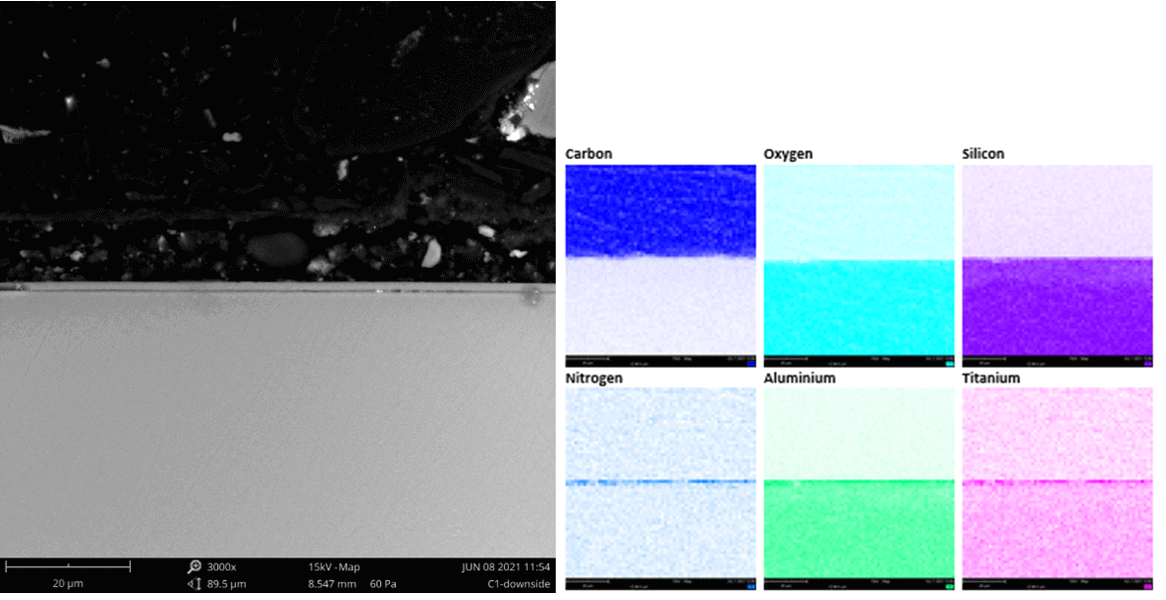

After a first selection, we acquired samples to proceed with the inspection and testing of these coatings. Here, the scanning electron microscope was decisive to define their exact compositions and dimensions and, most interestingly, to be able to formulate our own coatings. In this way, we developed laboratory samples optimized for our customer’s application and tested them in order to verify their performance under real conditions.

Challenge

- Need to apply an anti-scratch coating on a functional glass surface, with the same durability as the component

- Search for patents and commercial solutions to select a viable alternative in terms of cost and lead time

- Materials testing and contact with suppliers

Solution

- Realization of state-of-the-art anti-scratch coatings on glass

- Reverse engineering of commercial solutions through inspection and analysis of manufacturing processes, composition and physical-chemical properties

- Validation of functionality and durability of the developed and selected coatings in real conditions of use of the product