What was the challenge or problem to solve?

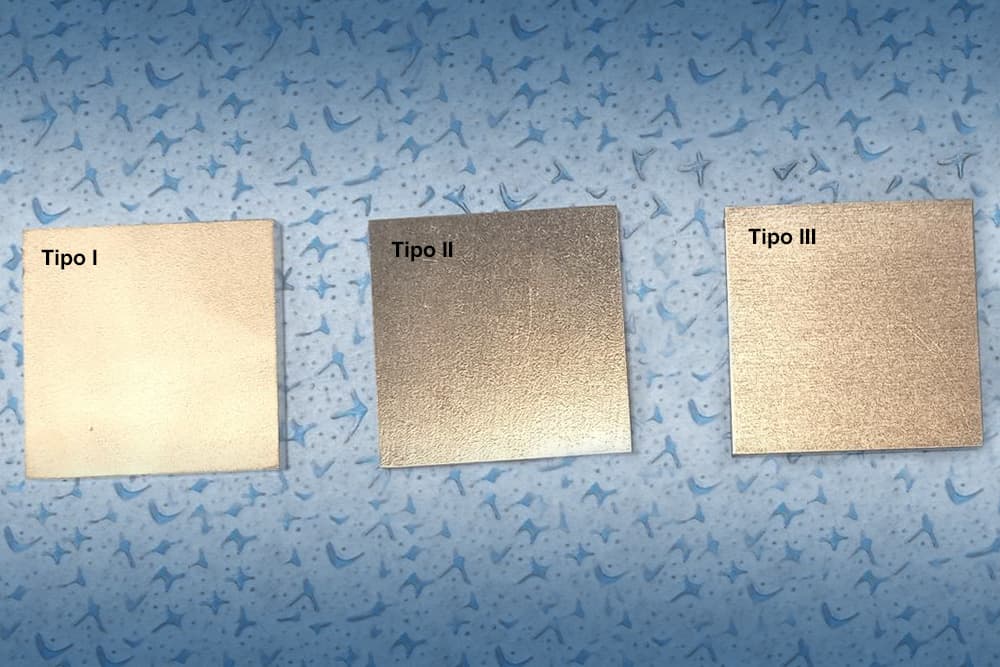

In this project we undertook a comparative study of various steels for a company in the industrial sector. Through different tests, we had to identify which material had the best wear resistance, taking into account the real working conditions in which it would be used.

In addition, the aim of this study was to reduce production costs, increasing the useful life of the product by using the most suitable materials.

INFINITIA developed a prototype to simulate the operating conditions, as there was no standard or norm that could simulate real conditions. After finding out how the machine worked and according to the specifications provided by the client, a customised set-up was designed in which to test the specimens of three steels. In addition, the Forensic Engineering area defined the type of test and parameter to be measured on the steels to determine the degree of wear of these materials.

After studying the behaviour of the steels in real working conditions and in different areas of the machine, it was possible to determine which one showed the least wear, so that the client could select the optimum steel for its application in the manufacture of machinery.

Firstly, a prototype was designed to meet the specifications provided by the client and to simulate the wear and tear that the materials would undergo. In order for the test to be as accurate as possible, it had to be carried out over a long period of time and recreate the usual conditions of use. In addition, the prototype had to have different areas in which to place the material, as the wear of the materials can be influenced by their location within the machine.

Once the prototype had been manufactured, the testing and measurement phase began. To evaluate material wear, the variation of different properties over time was studied. The monitoring of these parameters makes it possible to determine the wear suffered by each of the types of steel, as well as to calculate the corrosion rate of each of them.

In addition, a visual inspection was carried out using an optical microscope. Thanks to this test, it was possible to determine the type of corrosion that had been generated in each material.

From all this information, we produced a final report with the results and conclusions of the study. In this way, the client was able to estimate which steel was less susceptible to structural damage and was therefore the most suitable for their product.