What was the challenge or problem to solve?

In the competitive market of kitchen utensils, at INFINITIA, we faced the challenge of analyzing why a competitor’s cooking griddle offered better performance than our client’s product, and at a lower cost. This challenge not only involved thoroughly understanding the competitor’s product characteristics but also exploring our own capabilities for innovation and product improvement. The Forensic Engineering team undertook a reverse engineering process, addressing various physical and chemical characteristics of both griddles.

The project’s success was evidenced by the ability to identify clear differences between the two products. It was observed that variations in the finishing process significantly influenced the final characteristics of the griddle, providing very valuable information for future improvements and product development.

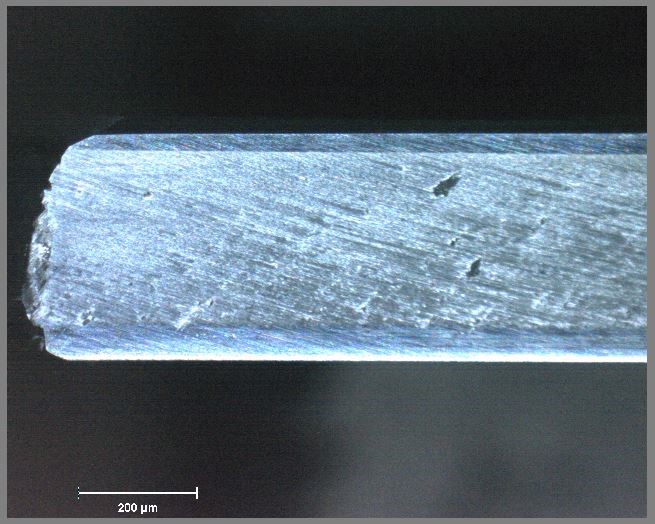

The study began with a visual analysis using an optical microscope to observe the different layers and determine the thickness of the electroplated layers of each griddle. This step was crucial to understand the basic structure and the finishing techniques applied.

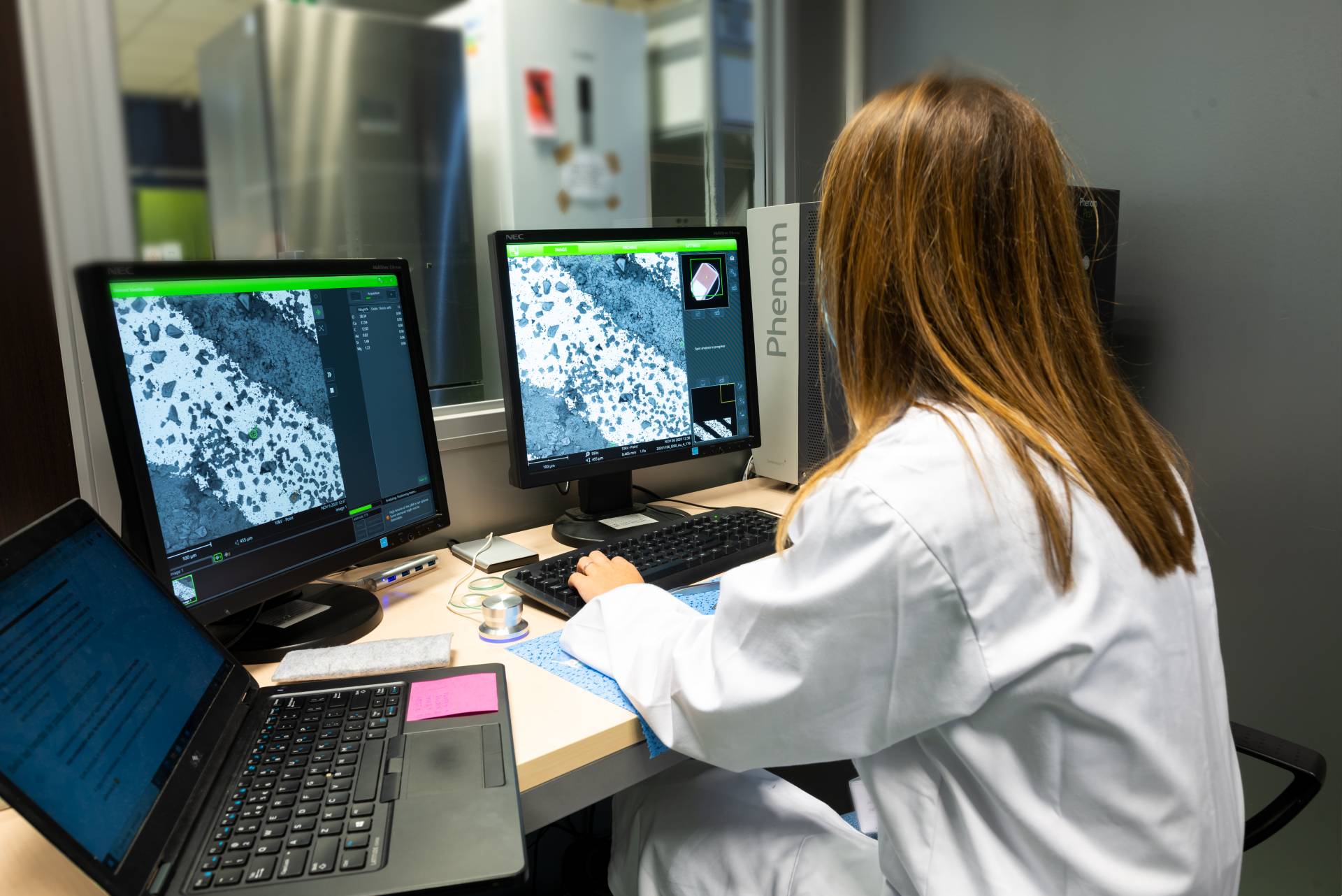

Subsequently, a topographical and compositional study was conducted using a SEM coupled with an EDX detector, allowing for a detailed evaluation of the chemical composition and the presence of possible inclusions in the analyzed surfaces.

This analysis was complemented by roughness measurements, where a profilometer was used to evaluate the surface uniformity of the griddles, which is a determining factor in stain retention and ease of cleaning.

In addition, wettability tests were conducted by measuring the contact angle to understand how the surfaces interact with liquids, an aspect that directly affects cooking and subsequent cleaning. Finally, aesthetic differences, such as color and gloss, were evaluated, which not only affect the product’s appearance but also the consumer’s perception of its quality and efficiency.

The benefits obtained from this study were significant, providing our client with concrete data to optimize the search for a more competitive product in terms of quality and cost.