What was the challenge or problem to solve?

Control of concentrations was critical, as high precision and different temperature ranges were required. Additionally, volatiles must be generated in different types of atmospheres, such as eg. synthetic air, or inert conditions with nitrogen.

How was it addressed or what was the solution?

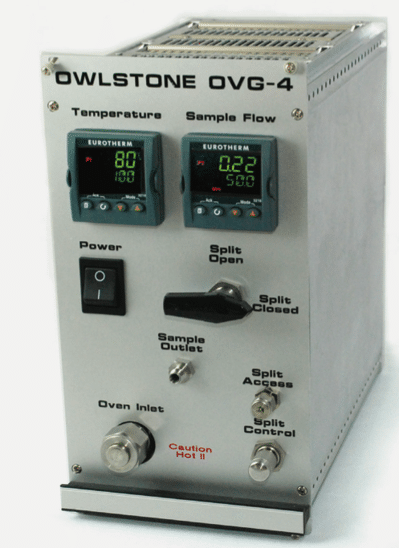

For this, the Materials Innovation team used an Owlstone OVG-4 brand volatiles generator, performing the appropriate calibrations and optimizations.

Control of concentration levels was obtained by preparing the permeation tubes and optimizing the concentrations of the solutions.

In addition to the concentration, other parameters such as temperature and gas flow rates were adjusted to ensure the target concentrations.

Once the study was completed, the client was provided with a custom protocol, as well as different calibration lines to adjust the final concentrations, and to be able to generate different gas atmospheres.

Challenge

- Need to generate gas atmospheres in a controlled way

- Commercial alternatives (eg gas bottles) were not feasible due to their high cost, or limited gas availability

- Have an internal protocol to adjust and reproduce different gas atmospheres

Solution

- A Owlstone OVG-4 volatile generator was available

- Different optimizations and calibrations were made

- A custom protocol and different calibration lines were designed to achieve different gas atmospheres