What was the challenge or problem to solve?

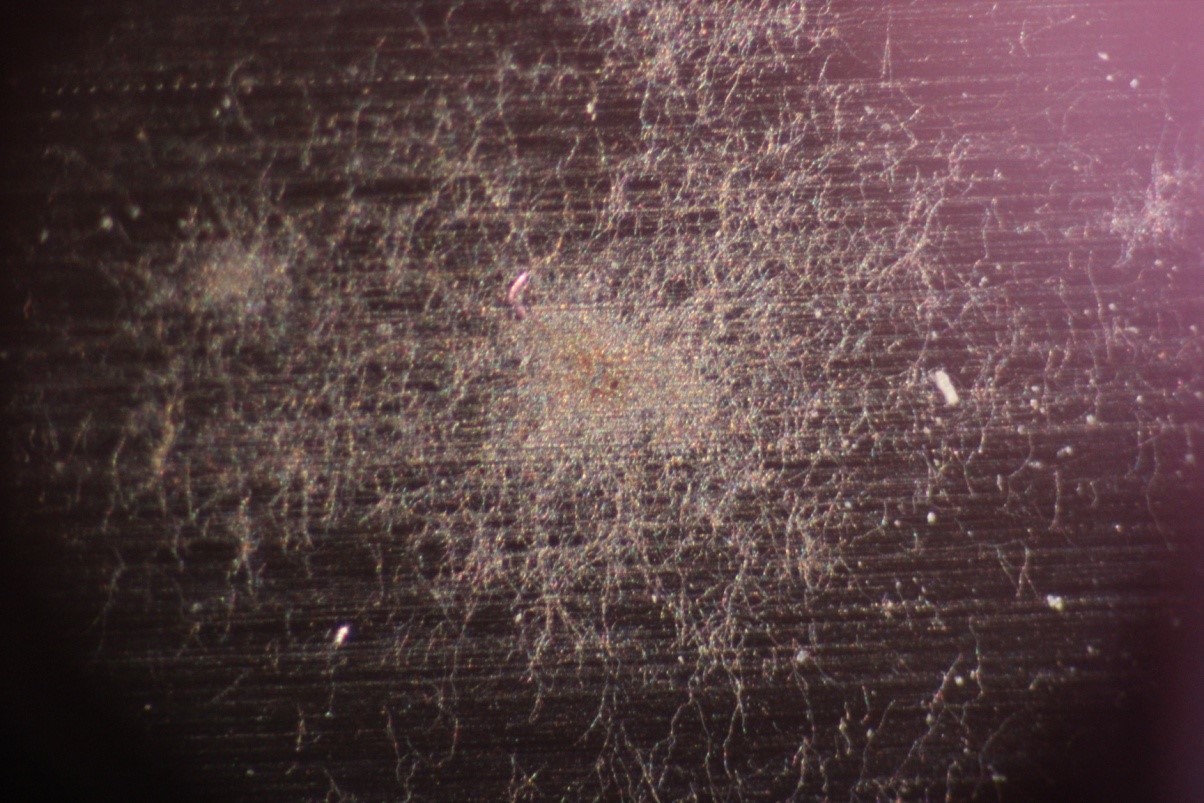

One of our clients presented us with a situation that started from that scenario. During the manufacturing process – the production was carried out on the Asian continent – a kind of stains appeared on the steel, similar to those produced by corrosion, approximately 1-2 centimeters in diameter.

How was it addressed or what was the solution?

We found the solution after a thorough investigation by our forensic engineering team. The detailed and joint work of studying the behavior of the material in each step of its transformation, from the initial phases to the factory finish, resulted in a specific analysis that became the true answer to the initial hypothesis. The stains were caused by fungi due to a contamination problem.

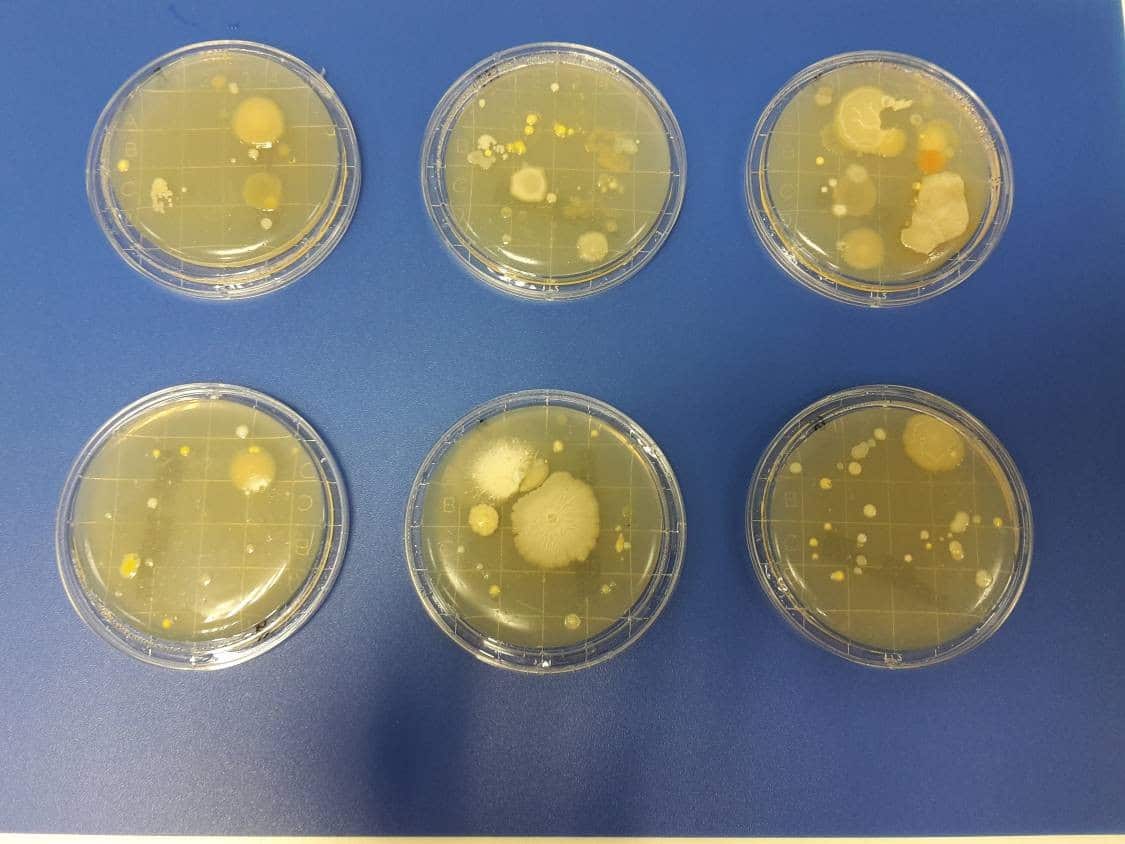

Through in-depth analysis developed in the microbiology laboratory, after several material tests and the corresponding quality control of the steel, critical points were found; such as areas with excessive humidity or areas the handling was incorrect. Thus, a “hygiene map” was drawn up that determined the necessary changes regarding air cleaning and jobs. Situation that can be extrapolated to other scenarios.

Challenge

- Analyze unknown stains that arose on steel parts in production

- Detect the source and look for potential solutions

Solution

- Investigation through Forensic Engineering

- Analysis of samples by the microbiology laboratory

- Design of a hygiene map with the critical points of contamination