What was the challenge or problem to solve?

Sometimes, when selecting a surface finish for a product, the visual appearance of the material is more important than its properties. As a result, the behaviour of the material may not be as expected and may lead to problems or failures.

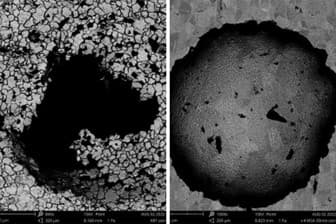

Firstly, we designed and executed a series of electrochemical tests using a potentiostat, with the aim of evaluating the corrosion resistance of the material. The advantage of this type of test compared to other traditional methods is the reduction in time and the increase in reproducibility, as the results obtained are quantitative. To guarantee the validity of the experiments, they were carried out in accordance with ISO 17475:2005.

With the data obtained, we produced a final report detailing the results of the behaviour of the surface finishes evaluated, and from which the customer selected the optimum finish for the manufacture of the product.