What was the challenge or problem to solve?

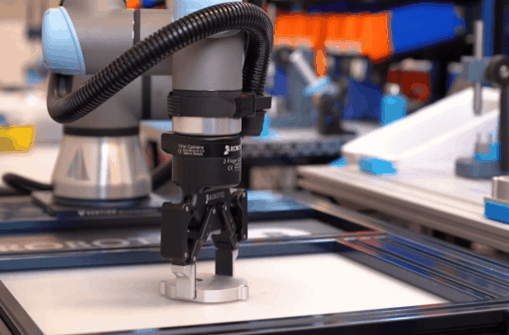

INFINITIA’s product development team tackled the design and prototyping of grippers for collaborative robots to handle various components with a single gripper unit in production.

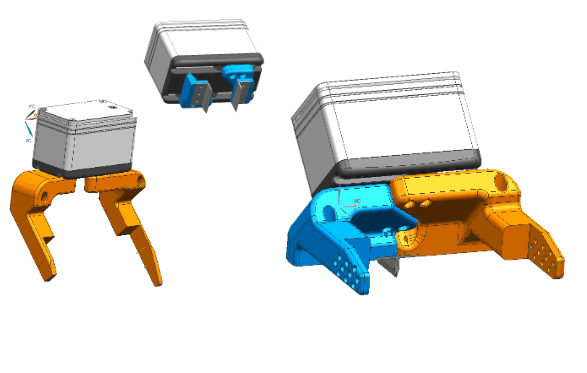

The process began with a detailed analysis of the components and the constraints of the assembly process, in order to ensure the compatibility of the design with the robot’s operations.

After developing individual mechanical solutions and validating them through 3D printing and field testing, the solutions were synthesised into an integrated, multifunctional design.

Thanks to the solution provided by INFINITIA, the customer was able to implement a versatile gripping solution, which allowed the collaborative robot to perform a variety of tasks without the need to change parts, significantly improving flexibility and efficiency in production.