What was the challenge or problem to solve?

This project emerged as a response to a trend: the need to develop a new air purifying device to achieve healthier air in enclosed spaces, especially following the COVID-19 pandemic. Furthermore, consumers demand solutions that not only improve air quality but also contribute to the aesthetics and comfort of their homes.

The challenge was to develop a device that, in addition to purifying and sanitizing the air, had a compact, safe, and efficient design. Moreover, it aimed to ensure a constant flow of purified air, facing the challenge of integrating an effective sanitization solution into a small-sized device.

During its development, significant technical obstacles were overcome, and ultimately, the design of a product ready for industrialization and commercialization was achieved.

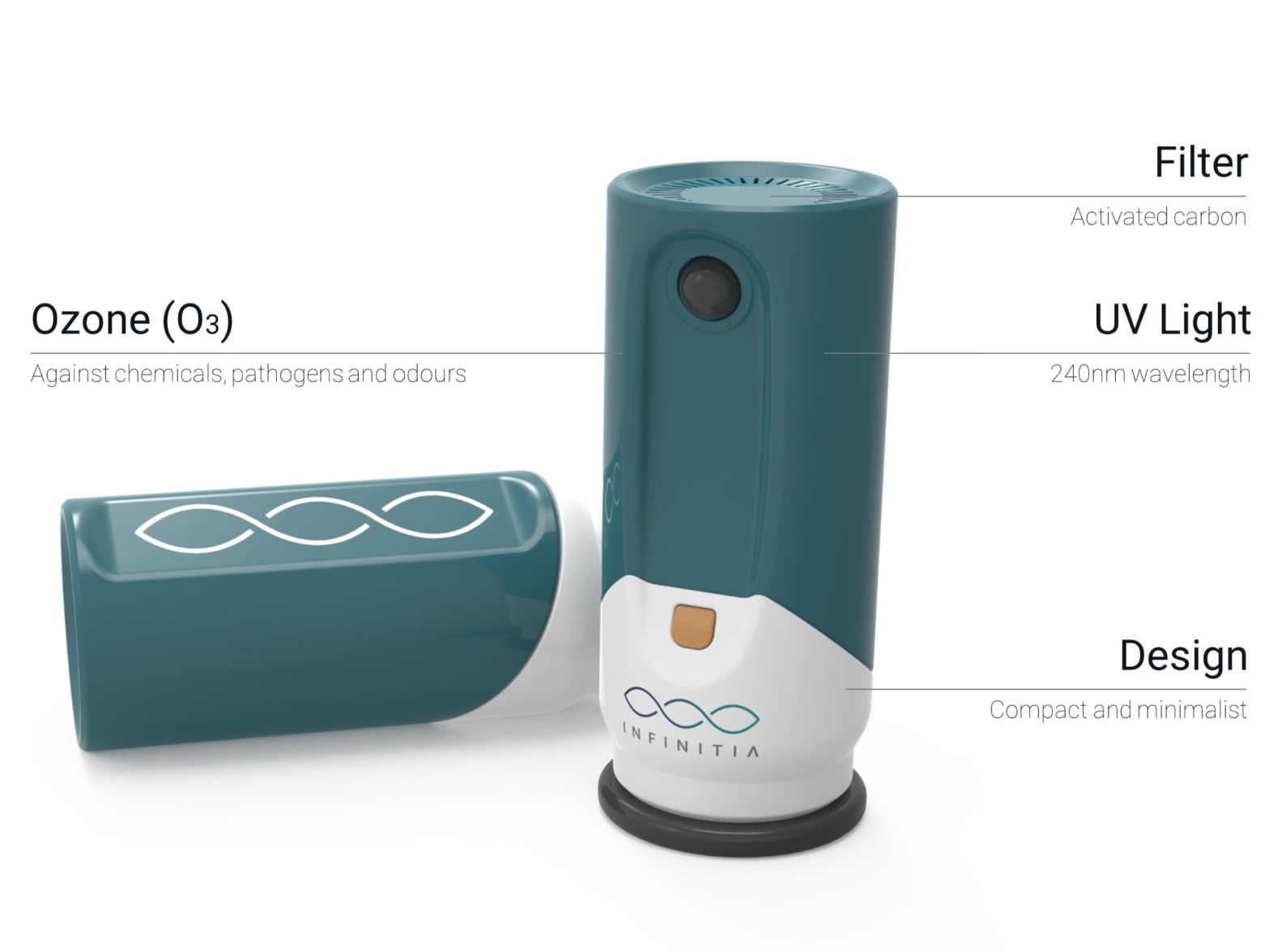

The innovations highlighted in this purifier were mainly its integration of ultraviolet light and ozone generation technologies as methods of eliminating pathogens, chemicals, and bad odours. This, along with activated carbon filters, constituted a comprehensive purification system that guaranteed an indoor environment that was not only cleaner but also safer.

To tackle this challenge, the Product Development Team at INFINITIA worked through the following phases.

Firstly, an exhaustive market study was conducted, including an analysis of the competition, consumer surveys, and focus groups, as well as technical feasibility assessments of the original idea. This phase allowed the identification of specific market needs and the definition of the essential technical requirements for the new device.

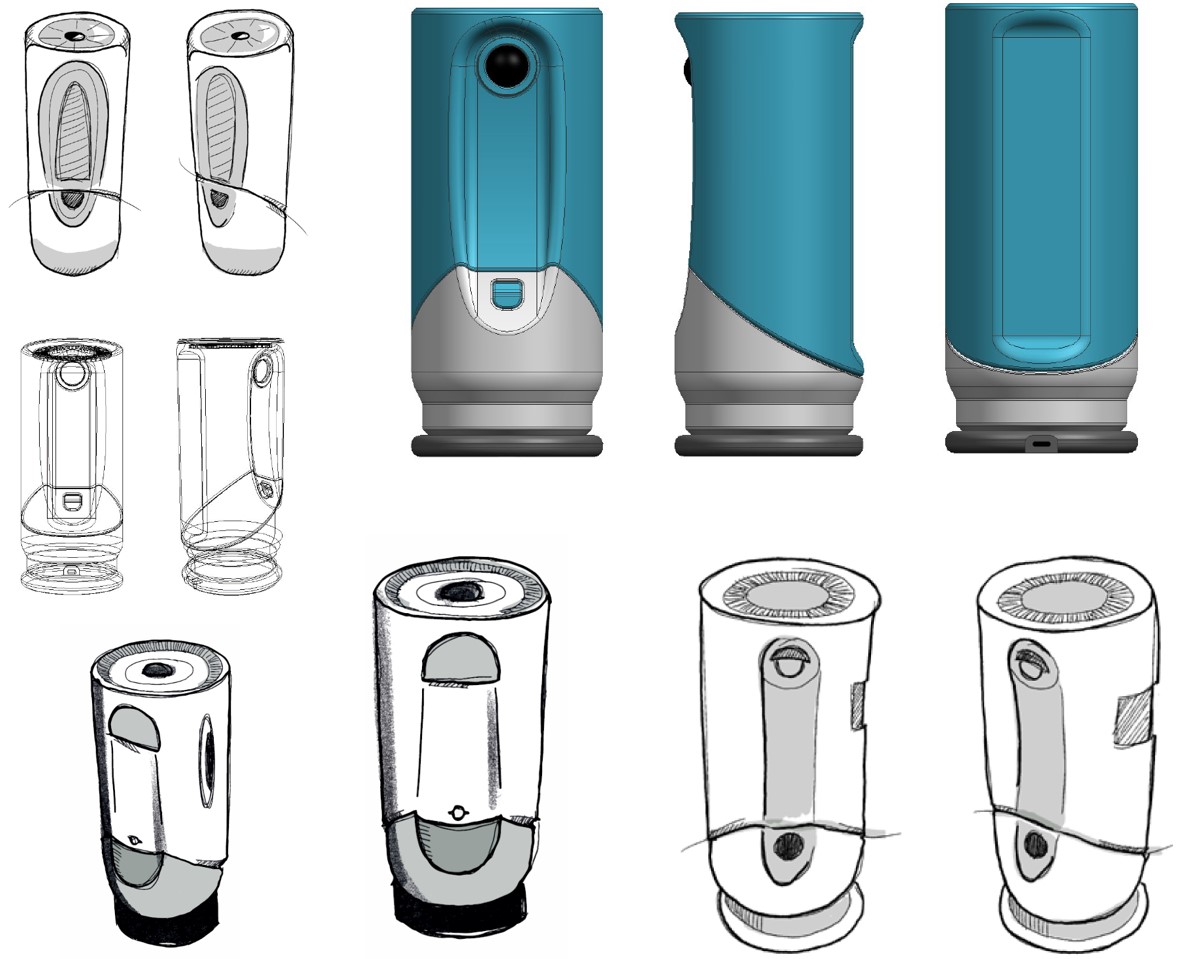

Based on these premises, the ideation and concept generation phase began. Brainstorming techniques, sketching, and computer illustration were used to conceptualize the most innovative solutions. The resulting concepts needed to be viable, feasible, and desirable, with a portable, compact design and a minimal interaction user interface.

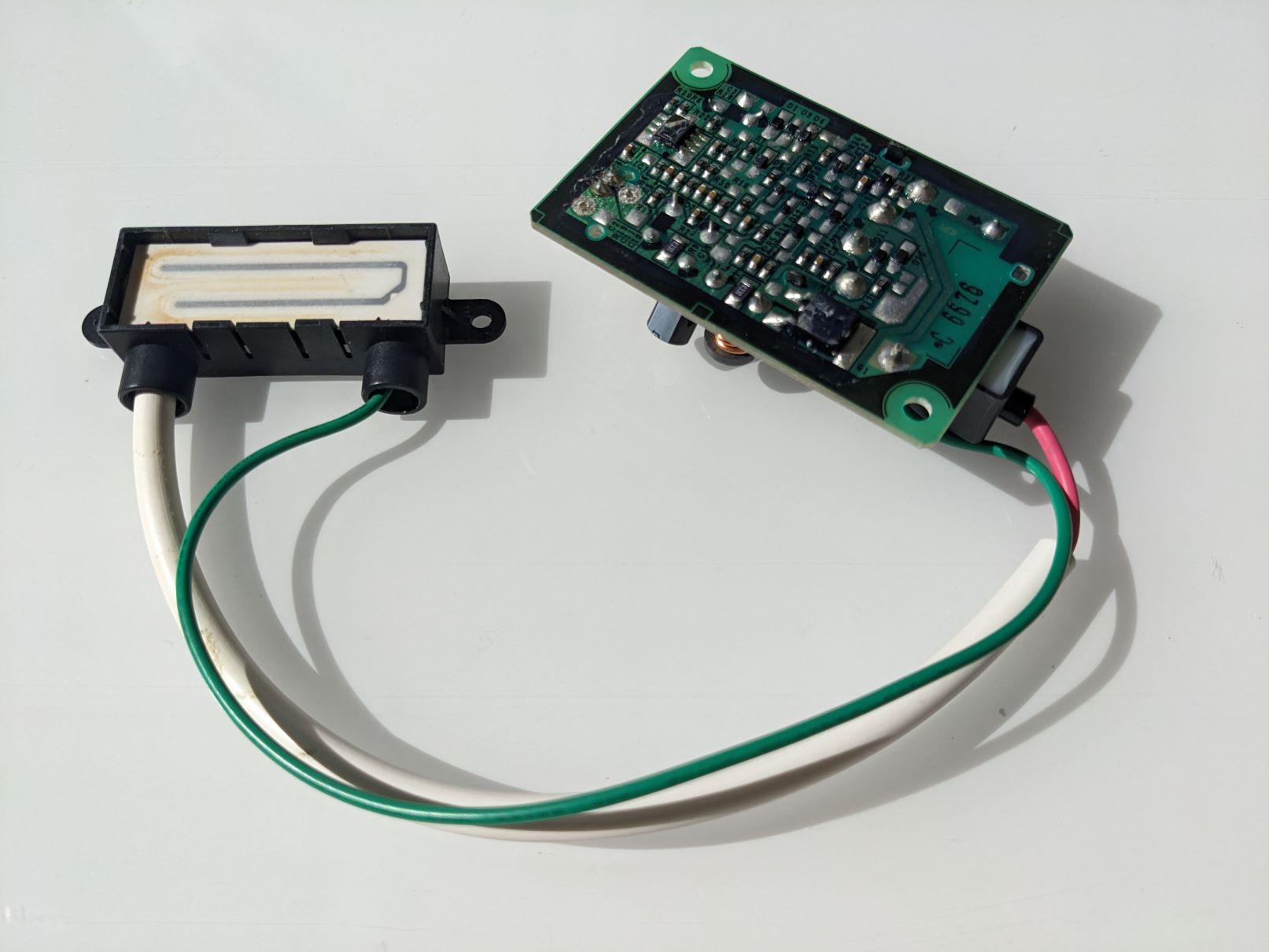

Subsequently, functional prototypes were developed, with which concept tests were performed for the validation of the proposals. This was achieved through the 3D and functional design of the device, rapid prototyping, and specific sanitization technology tests. Thus, the sanitization technology with ozone and UV, the aesthetics, and the user interface of the device could be validated. This phase was crucial for identifying risks, opportunities, and thus making the necessary adjustments to the design.

The final phase involved refining the proposal, optimizing the design for industrial manufacturing, and conducting user tests with a pre-series of the product. These activities ensured that the device met quality standards and design specifications, identifying potential problems before large-scale production.

The result was a highly technological product that did not sacrifice performance for being compact and minimalist in design, offering a concrete response to the growing demand for clean air solutions, combining technological innovation, efficiency, and design in a device that promises to transform our everyday environment.