What was the challenge or problem to solve?

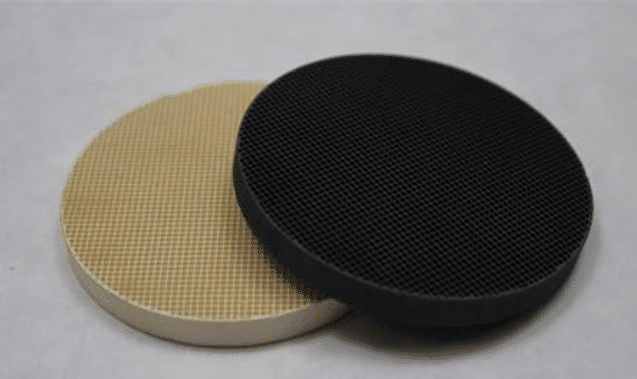

This setup was used to study catalytic filters as a preventive technology for the degradation of volatile organic compounds and unhealthy substances.

How was it addressed or what was the solution?

In order to know the effectiveness of the catalytic filters, it was necessary to build a laboratory setup that allowed controlling several variables and conditions (temperature, concentration of gases, flows …), and tests could be carried out in a controlled and reproducible way.

A key point of the setup was the generation of volatile organic compounds in certain concentrations. For this, an Owlstone OVG-4 brand volatiles generator was available, making the appropriate calibrations and optimizations.

Finally, the results were monitored by a highly sensitive multi-gas team and evaluated by gas chromatography and mass spectrometry.

Challenge

- Evaluation of the gas degradation efficiency of different catalytic filters

- Design a versatile setup through which to modify different parameters in a controlled and reproducible way

- Elimination of volatile organic compounds and unhealthy substances

Solution

- Construction of a laboratory setup

- Generation of volatile organic compounds in determined concentrations

- Monitoring of volatile organic compounds with a multi-gas equipment

- Evaluation of compounds by gas chromatography